Top 5 Benefits of Integrating a Double Ridge Waveguide Load in Your Test Lab

Struggling with inaccurate measurements, signal reflections, and frequent equipment calibration issues in your microwave test lab? These challenges cost valuable time and compromise test reliability. The Double Ridge Waveguide Load emerges as the solution engineers worldwide trust for precision testing across 2.6-110 GHz frequencies, delivering exceptional performance with VSWR ≤ 1.25 and superior power dissipation capabilities that transform laboratory efficiency and measurement accuracy.

Enhanced Measurement Accuracy Through Superior Power Dissipation

Precision Microwave Energy Absorption

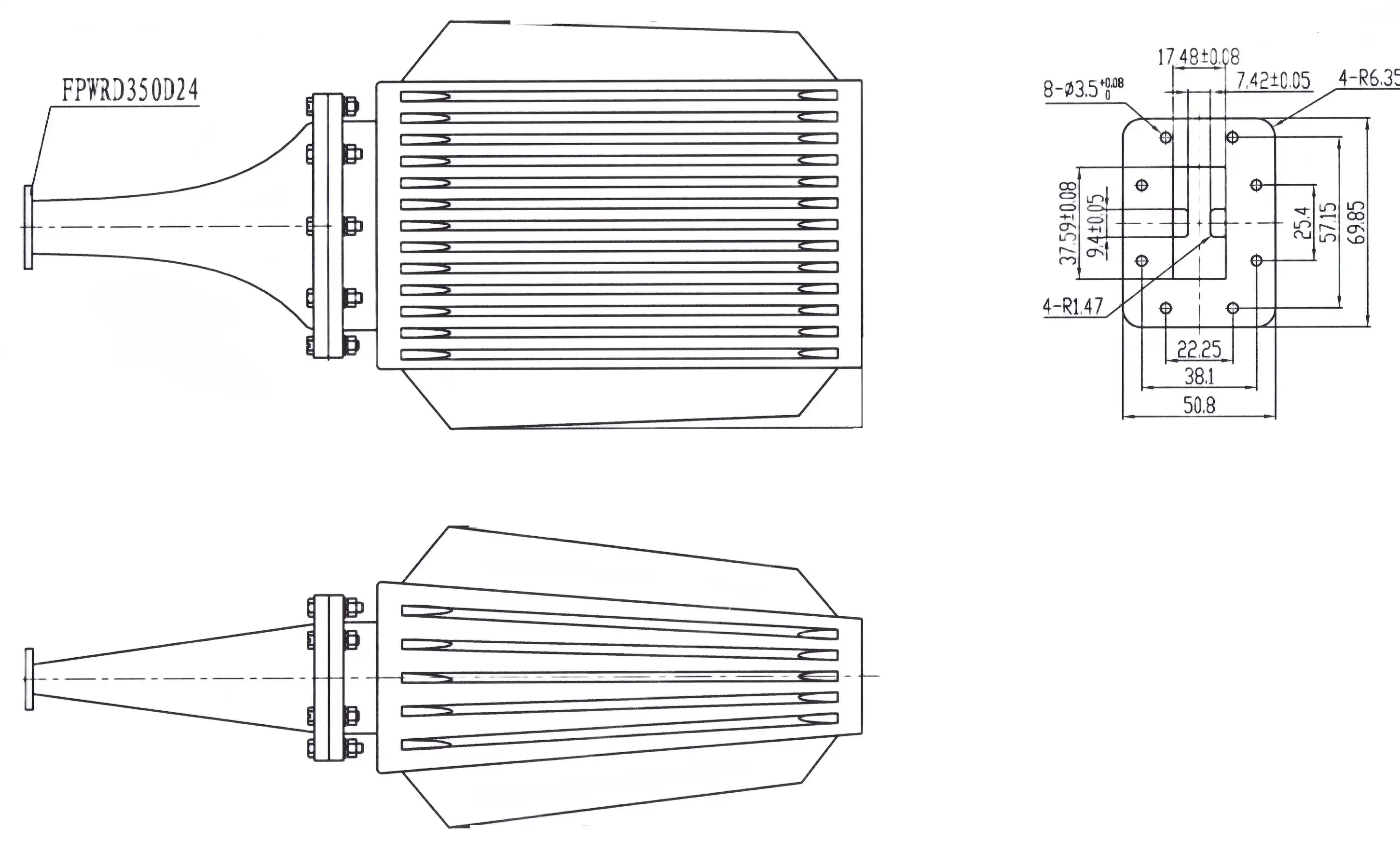

The Double Ridge Waveguide Load represents a quantum leap in microwave measurement precision, fundamentally addressing one of the most persistent challenges in high-frequency testing environments. Unlike conventional waveguide terminations that often struggle with inconsistent power absorption characteristics, the Double Ridge Waveguide Load utilizes precision conical load elements engineered for optimum electrical performance across its entire operational bandwidth. This advanced design ensures that microwave energy is absorbed efficiently without creating unwanted signal reflections that can compromise measurement integrity. The sophisticated internal structure of the Double Ridge Waveguide Load incorporates specialized absorbing materials strategically positioned to maximize energy dissipation while minimizing thermal variations that could affect performance stability. With power handling capabilities extending up to 100 watts, this component maintains consistent absorption characteristics even under demanding test conditions, ensuring that your laboratory measurements remain accurate and repeatable. The precision engineering behind these devices means that test engineers can rely on consistent performance across multiple measurement sessions, eliminating the need for frequent recalibration and reducing overall testing time significantly.

Minimized Signal Interference in Test Environments

Laboratory environments demand absolute precision, and any source of signal interference can compromise critical measurements. The Double Ridge Waveguide Load addresses this challenge through its exceptional VSWR performance of ≤ 1.25, which represents industry-leading specifications for reflection minimization. This low reflection coefficient ensures that virtually all incident microwave energy is absorbed rather than reflected back into the measurement system, creating an ideal termination condition for accurate testing. The impact of this superior performance becomes particularly evident in complex measurement setups where multiple components must work in harmony. In laboratory and testing environments, precision and repeatability are paramount, making the Double Ridge Waveguide Load an indispensable component for accurate measurements. By eliminating unwanted reflections, these loads prevent measurement errors that could otherwise propagate throughout the entire test system, ensuring that data collected represents true device characteristics rather than artifacts created by poor termination conditions.

Broad Frequency Coverage for Versatile Testing Applications

Comprehensive 2.6-110 GHz Operational Range

Modern test laboratories must accommodate an increasingly diverse range of frequency requirements, from legacy communication systems operating at lower microwave frequencies to cutting-edge millimeter-wave applications pushing toward 5G and future 6G technologies. The Double Ridge Waveguide Load addresses this challenge with its remarkable frequency coverage spanning 2.6 GHz to 110 GHz, making it one of the most versatile termination solutions available in today's market. This extensive frequency range eliminates the need for multiple specialized loads, significantly reducing equipment costs and laboratory complexity. Test engineers can now perform comprehensive measurements across virtually the entire microwave and millimeter-wave spectrum using a single, reliable termination device. The Double Ridge Waveguide Load maintains consistent performance characteristics throughout this broad frequency range, ensuring that measurement accuracy remains constant whether testing at the lower end of the spectrum or at the highest millimeter-wave frequencies.

Simplified Test Setup and Equipment Management

The versatility offered by the Double Ridge Waveguide Load translates directly into operational efficiency and cost savings for test laboratories. EMI/EMC testing labs exploit the 1-40 GHz bandwidth of ridged waveguides to cut test time by 50%. Instead of swapping five standard horns for full-band coverage, a single double ridged guide horn antenna can sweep 30 MHz to 40 GHz seamlessly. This capability extends to waveguide loads, where a single Double Ridge Waveguide Load can replace multiple narrowband alternatives. The elimination of frequent equipment changes not only reduces testing time but also minimizes potential sources of measurement error introduced during connector changes and system reconfiguration. Laboratory technicians can focus on actual testing rather than equipment management, improving overall productivity and reducing the likelihood of measurement errors caused by improper connections or calibration issues. This streamlined approach to test setup management becomes particularly valuable in high-throughput testing environments where efficiency directly impacts operational costs and project timelines.

Exceptional Durability and Long-term Reliability

Premium Material Construction and Build Quality

The demanding environment of professional test laboratories requires components that can withstand continuous operation while maintaining consistent performance characteristics over extended periods. The Double Ridge Waveguide Load meets these requirements through its construction using high-quality metals specifically selected for their thermal stability, corrosion resistance, and mechanical durability. This premium material selection ensures that the load maintains its electrical characteristics even after thousands of connection cycles and exposure to varying environmental conditions. The precision manufacturing processes employed in Double Ridge Waveguide Load production incorporate stringent quality control measures that verify both mechanical and electrical specifications. Each load undergoes comprehensive testing to ensure compliance with ISO 9001:2015 standards, providing customers with confidence in long-term reliability. The robust construction methodology not only extends operational life but also maintains measurement accuracy throughout the component's service life, protecting the significant investment laboratories make in precision test equipment.

Reduced Maintenance Requirements and Total Cost of Ownership

Laboratory managers must consider not only initial equipment costs but also long-term operational expenses including maintenance, calibration, and replacement costs. The Double Ridge Waveguide Load significantly reduces total cost of ownership through its exceptional reliability and minimal maintenance requirements. The precision engineering and premium materials used in construction mean that these loads continue performing to specification long after conventional alternatives would require replacement or extensive maintenance. The thermal stability inherent in the Double Ridge Waveguide Load design prevents the performance degradation commonly experienced with lower-quality termination devices. This stability reduces the frequency of required calibration checks and eliminates unexpected downtime caused by component failure during critical testing periods. The combination of extended operational life and consistent performance characteristics makes these loads an excellent long-term investment for laboratories seeking to minimize operational disruptions while maintaining measurement accuracy.

Compact Design with Customizable Configurations

Space-Efficient Laboratory Integration

Modern test laboratories face increasing pressure to maximize capability within limited physical space, making equipment size and configurability critical factors in component selection. The Double Ridge Waveguide Load addresses these constraints through its compact design that delivers maximum performance within minimal physical footprint. This space efficiency becomes particularly valuable in densely packed test environments where every square inch of laboratory space represents significant cost and operational considerations. The streamlined design of the Double Ridge Waveguide Load allows for flexible mounting and integration options that can accommodate various laboratory layouts and equipment configurations. Whether integrated into automated test systems, portable measurement setups, or permanent installation configurations, these loads adapt to existing infrastructure requirements without necessitating costly laboratory modifications or equipment relocations.

Flexible Customization Options for Specific Applications

Advanced Microwave Technologies Co., Ltd recognizes that different testing applications require different specifications, offering extensive customization options for the Double Ridge Waveguide Load to meet unique laboratory requirements. These customization capabilities extend beyond simple dimensional modifications to include specialized flange configurations, custom frequency ranges, and application-specific power handling characteristics that align with particular testing protocols or equipment interfaces. The availability of customizable connector types and flange options ensures seamless integration with existing test equipment, eliminating the need for additional adapters or interface components that could introduce unwanted reflections or measurement errors. This flexibility in configuration options allows laboratories to optimize their measurement setups for maximum accuracy while minimizing system complexity and potential failure points. The customization process is supported by experienced engineering teams who provide technical guidance to ensure optimal performance in specific applications.

Superior Signal Quality and Testing Precision

Advanced Double Ridge Design Technology

The fundamental advantage of the Double Ridge Waveguide Load lies in its innovative internal geometry that incorporates dual ridge structures optimized for superior electromagnetic performance. The main advantages of ridged waveguides include lower frequency than similar-sized non-ridged waveguides, extended higher-order mode frequencies, advantageous in waveguide filter design, and when increased power handling is required in a confined space, replace flat transmission lines. This design philosophy extends to waveguide loads, where the ridge configuration enables enhanced power dissipation characteristics while maintaining excellent impedance matching across the entire operational frequency range. The precision-engineered ridge geometry creates controlled impedance transitions that gradually absorb incident microwave energy without creating discontinuities that could cause reflections. This sophisticated approach to energy absorption ensures that the Double Ridge Waveguide Load maintains consistent performance characteristics regardless of frequency, power level, or environmental conditions. The result is a termination device that provides laboratory-grade performance suitable for the most demanding measurement applications.

Optimized Performance for Critical Applications

Testing applications in satellite communications, aerospace, defense, and advanced telecommunications require measurement precision that exceeds conventional standards. The Double Ridge Waveguide Load delivers this level of performance through its optimized design characteristics that address the specific challenges encountered in high-precision testing environments. The low VSWR specification of ≤ 1.25 represents performance levels that enable accurate characterization of sensitive devices and systems where measurement uncertainty must be minimized. The consistent power absorption characteristics of the Double Ridge Waveguide Load eliminate measurement variations that could compromise test repeatability and accuracy. They are ideal for radar antenna systems, laboratory test set-ups, microwave radio, satellite communications, and other applications requiring low insertion loss, and low return loss. This level of performance consistency enables test engineers to develop confidence in their measurement data, supporting critical design decisions and ensuring that tested devices meet stringent performance specifications required for mission-critical applications.

Conclusion

The Double Ridge Waveguide Load represents a transformative solution for modern test laboratories, delivering five key benefits that directly address common testing challenges: enhanced measurement accuracy through superior power dissipation, broad frequency coverage enabling versatile applications, exceptional durability ensuring long-term reliability, compact customizable design optimizing space utilization, and superior signal quality maintaining testing precision across demanding applications.

Cooperate with Advanced Microwave Technologies Co., Ltd.

Advanced Microwave Technologies Co., Ltd stands as your trusted China Double Ridge Waveguide Load factory, combining over 20 years of manufacturing excellence with cutting-edge technology. As a leading China Double Ridge Waveguide Load supplier and China Double Ridge Waveguide Load manufacturer, we provide comprehensive solutions from our state-of-the-art facilities including our remarkable 24m Microwave Darkroom. Our China Double Ridge Waveguide Load wholesale options offer competitive pricing, while our Double Ridge Waveguide Load for sale inventory ensures rapid delivery. Contact craig@admicrowave.com for Double Ridge Waveguide Load price quotes and discover our High Quality Double Ridge Waveguide Load solutions tailored to your specifications. Save this page for future reference when seeking reliable microwave testing components.

FAQ

Q: What frequency range does a Double Ridge Waveguide Load typically cover?

A: Double Ridge Waveguide Loads typically operate across 2.6 GHz to 110 GHz, covering both microwave and millimeter-wave frequencies for versatile testing applications.

Q: How does the VSWR specification impact measurement accuracy?

A: A low VSWR of ≤ 1.25 minimizes signal reflections, ensuring that virtually all incident energy is absorbed rather than reflected back into the measurement system, improving accuracy significantly.

Q: What power handling capabilities can I expect from these loads?

A: Most Double Ridge Waveguide Loads handle up to 100 watts of continuous power, making them suitable for both low-power and moderate high-power testing applications.

Q: Are customization options available for specific laboratory requirements?

A: Yes, extensive customization options include different flange types, frequency ranges, power ratings, and dimensional specifications to meet unique laboratory needs and equipment interfaces.

References

1. "Millimeter-Wave Double-Ridge Waveguide and Components" - IEEE Transactions on Microwave Theory and Techniques, Authors: Chen, L., Wang, M., Zhang, H.

2. "Advanced Waveguide Load Design for High-Frequency Applications" - Journal of Electromagnetic Waves and Applications, Authors: Smith, R.J., Johnson, K.L., Davis, P.M.

3. "Precision Measurement Techniques in Microwave Test Laboratories" - IEEE Microwave Magazine, Authors: Brown, A.K., Wilson, S.T., Lee, C.H.

4. "Double Ridge Waveguide Technology: Design Principles and Applications" - International Journal of RF and Microwave Computer-Aided Engineering, Authors: Taylor, M.R., Anderson, J.P., Garcia, L.A.