The Role of a Waveguide Probe Coupler in High-Frequency Communication

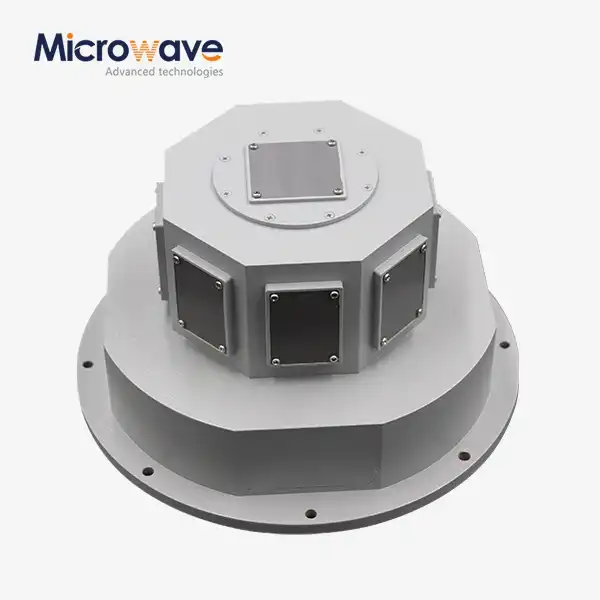

In the rapidly evolving landscape of high-frequency communication systems, waveguide probe couplers have emerged as indispensable components that bridge the gap between signal transmission and measurement accuracy. A Waveguide Probe Coupler serves as a critical interface that enables precise signal sampling, monitoring, and measurement within waveguide systems without disrupting the primary signal path. These sophisticated devices facilitate the extraction of a controlled portion of electromagnetic energy from the main transmission line, allowing engineers to monitor signal characteristics, perform system diagnostics, and ensure optimal performance across various frequency bands. As communication systems advance toward higher frequencies and greater precision requirements, the role of waveguide probe couplers becomes increasingly vital in maintaining signal integrity and enabling accurate measurements in applications ranging from satellite communications to aerospace defense systems.

Understanding the Fundamental Principles of Waveguide Probe Couplers

Electromagnetic Coupling Mechanisms in Waveguide Systems

The electromagnetic coupling mechanism within a Waveguide Probe Coupler operates on the fundamental principle of controlled electromagnetic field interaction between the main waveguide and a sampling probe. When electromagnetic waves propagate through a rectangular or circular waveguide, they create specific field patterns that vary depending on the operating mode and frequency. The probe coupler strategically intercepts a small fraction of this electromagnetic energy through either electric field coupling or magnetic field coupling, depending on the probe orientation and design configuration. Advanced Microwave Technologies Co., Ltd has perfected this coupling mechanism through decades of research and development, ensuring that their waveguide probe couplers maintain exceptional coupling accuracy while minimizing insertion loss. The coupling strength is typically expressed in decibels and can range from 10 dB to 30 dB, depending on the specific application requirements. The probe's physical dimensions, including its length, width, and penetration depth into the waveguide, directly influence the coupling coefficient and frequency response characteristics. Modern Waveguide Probe Coupler designs incorporate precise mechanical tolerances and advanced materials to achieve consistent coupling performance across wide frequency ranges, ensuring reliable signal sampling for critical communication applications.

Signal Integrity and Measurement Precision Factors

Signal integrity preservation represents one of the most critical aspects of Waveguide Probe Coupler performance, as any degradation in signal quality can compromise the accuracy of measurements and system diagnostics. The insertion loss characteristics of a probe coupler directly impact the main signal path, with high-quality couplers achieving insertion losses as low as 1 dB while maintaining excellent directivity performance above 20 dB. Advanced Microwave Technologies Co., Ltd implements rigorous quality control measures throughout the manufacturing process to ensure that each Waveguide Probe Coupler meets stringent performance specifications. The directivity parameter becomes particularly crucial in applications where reflected signals must be accurately measured or isolated from forward-traveling waves. Temperature stability and mechanical precision play vital roles in maintaining measurement accuracy, especially in aerospace and defense applications where environmental conditions can vary significantly. The frequency response flatness of a probe coupler determines its ability to provide consistent coupling across the entire operating bandwidth, which is essential for broadband communication systems and wideband measurement applications. Modern probe coupler designs incorporate advanced materials such as brass, stainless steel, and aluminum alloys to optimize both electrical performance and mechanical stability under varying environmental conditions.

Design Optimization for High-Frequency Applications

High-frequency communication systems place demanding requirements on Waveguide Probe Coupler design, necessitating careful optimization of geometric parameters and material selections to achieve optimal performance. The probe geometry, including its shape, size, and positioning within the waveguide, must be precisely calculated to ensure proper impedance matching and minimize unwanted reflections that could degrade system performance. Advanced electromagnetic simulation tools are employed to model the coupling behavior and optimize the design parameters before physical prototyping begins. Advanced Microwave Technologies Co., Ltd utilizes state-of-the-art design methodologies and extensive electromagnetic modeling to create Waveguide Probe Coupler solutions that excel in demanding high-frequency applications. The transition from the probe to the output connector represents a critical design challenge, as impedance discontinuities in this region can create unwanted reflections and compromise measurement accuracy. Surface roughness and manufacturing tolerances become increasingly important at higher frequencies, where even minor imperfections can significantly impact electrical performance. The selection of appropriate dielectric materials for probe insulation and mechanical support structures requires careful consideration of loss tangent, dielectric constant stability, and thermal expansion characteristics to ensure reliable operation across the entire frequency range and temperature spectrum.

Critical Applications and Performance Requirements

Satellite Communication System Integration

Satellite communication systems represent one of the most demanding applications for Waveguide Probe Coupler technology, where signal quality and measurement precision directly impact communication reliability and coverage area. In satellite ground stations, probe couplers enable continuous monitoring of uplink and downlink signal power levels, allowing operators to optimize transmission parameters and detect potential system degradation before it affects service quality. The harsh environmental conditions encountered in satellite applications, including extreme temperatures, humidity variations, and mechanical vibrations, require Waveguide Probe Coupler designs that maintain stable performance throughout extended operational periods. Advanced Microwave Technologies Co., Ltd provides specialized probe couplers designed specifically for satellite communication applications, incorporating ruggedized construction and enhanced environmental protection features. The frequency ranges commonly used in satellite communications, including X-band, Ku-band, and Ka-band, each present unique design challenges that must be addressed through careful engineering and extensive testing. Signal monitoring capabilities provided by probe couplers enable real-time assessment of signal-to-noise ratios, carrier-to-interference ratios, and other critical performance metrics that determine communication link quality. The ability to perform non-intrusive signal sampling allows satellite operators to maintain continuous service while conducting system diagnostics and performance optimization procedures.

Radar and Defense System Applications

Modern radar and defense systems rely heavily on Waveguide Probe Coupler technology to achieve the precision and reliability required for critical military applications. These systems often operate across multiple frequency bands simultaneously and require probe couplers capable of maintaining consistent performance characteristics across wide bandwidth ranges. The coupling accuracy and directivity performance of probe couplers directly impact radar system calibration procedures and measurement precision, which are essential for target detection and tracking applications. Advanced Microwave Technologies Co., Ltd has developed specialized Waveguide Probe Coupler solutions for defense applications, incorporating enhanced security features and ruggedized construction to meet stringent military specifications. Phased array radar systems present particularly challenging requirements, as probe couplers must maintain phase coherence and amplitude accuracy across large arrays of antenna elements. The high power levels encountered in many radar applications require probe couplers designed to handle significant RF power without degradation or damage, while still providing accurate signal sampling capabilities. Environmental conditions in military applications can be extremely harsh, requiring probe couplers that maintain performance integrity under conditions including temperature extremes, shock, vibration, and electromagnetic interference. The reliability and longevity of Waveguide Probe Coupler components in defense applications are critical factors, as system failures can have serious operational consequences.

Telecommunications Infrastructure and 5G Networks

The rapid deployment of 5G networks and advanced telecommunications infrastructure has created new opportunities and challenges for Waveguide Probe Coupler applications in high-frequency communication systems. Base station manufacturers increasingly rely on precise signal monitoring and measurement capabilities to optimize network performance and ensure regulatory compliance across multiple frequency bands. The transition to millimeter-wave frequencies in 5G applications requires probe couplers capable of maintaining excellent performance characteristics at frequencies approaching 110 GHz, pushing the boundaries of conventional design approaches. Advanced Microwave Technologies Co., Ltd addresses these challenges through innovative Waveguide Probe Coupler designs that incorporate advanced materials and precision manufacturing techniques optimized for millimeter-wave applications. Network operators utilize probe couplers for continuous monitoring of signal quality parameters, including error vector magnitude, adjacent channel power ratios, and spectral mask compliance measurements. The compact size requirements of modern telecommunications equipment necessitate Waveguide Probe Coupler designs that maximize performance while minimizing physical footprint and weight. Integration challenges in dense equipment environments require careful consideration of electromagnetic compatibility and isolation characteristics to prevent interference between adjacent systems. The reliability requirements of telecommunications infrastructure demand probe couplers that maintain stable performance over extended operational periods with minimal maintenance requirements.

Advanced Technologies and Future Developments

Precision Manufacturing and Quality Assurance

The manufacturing precision required for high-performance Waveguide Probe Coupler components demands advanced production techniques and comprehensive quality assurance procedures to ensure consistent performance across all units. Computer-controlled machining processes enable the achievement of dimensional tolerances measured in micrometers, which are essential for maintaining coupling accuracy and frequency response consistency. Advanced Microwave Technologies Co., Ltd has invested heavily in state-of-the-art manufacturing equipment and measurement capabilities, including their renowned 24m Microwave Darkroom facility that provides unparalleled measurement accuracy up to 110 GHz. The quality control process for each Waveguide Probe Coupler includes comprehensive electrical testing, mechanical inspection, and environmental validation to ensure compliance with stringent performance specifications. Material selection and treatment processes play crucial roles in achieving the required electrical and mechanical properties, with careful attention paid to surface finish quality, conductivity optimization, and long-term stability characteristics. Traceability systems enable complete documentation of manufacturing processes and performance verification results, providing customers with confidence in product quality and reliability. Statistical process control methodologies are employed throughout the manufacturing process to identify and eliminate sources of variation that could impact product performance or reliability.

Customization Capabilities and OEM Services

The diverse requirements of modern high-frequency communication applications necessitate Waveguide Probe Coupler solutions that can be customized to meet specific performance and integration requirements. Advanced Microwave Technologies Co., Ltd offers comprehensive OEM services that enable customers to obtain probe couplers optimized for their unique applications and specifications. Custom frequency ranges, coupling levels, and mechanical configurations can be designed and manufactured to address specific system requirements that cannot be met with standard product offerings. The engineering team at Advanced Microwave Technologies Co., Ltd works closely with customers throughout the design and development process to ensure that custom Waveguide Probe Coupler solutions meet all performance objectives while maintaining cost-effectiveness and manufacturability. Rapid prototyping capabilities enable quick turnaround times for custom designs, allowing customers to evaluate performance characteristics and make necessary modifications before committing to full-scale production. Material options including brass, stainless steel, and aluminum alloys provide flexibility in optimizing electrical performance, environmental resistance, and cost considerations for specific applications. Technical support services extend beyond the initial design phase to include installation guidance, performance optimization recommendations, and troubleshooting assistance throughout the product lifecycle.

Integration with Modern Test and Measurement Systems

Modern test and measurement systems increasingly rely on Waveguide Probe Coupler technology to provide accurate and reliable signal sampling capabilities for automated test equipment and network analyzers. The integration of probe couplers with digital signal processing systems enables real-time signal analysis and automated measurement procedures that significantly improve testing efficiency and accuracy. Advanced Microwave Technologies Co., Ltd designs Waveguide Probe Coupler products with full consideration of integration requirements for modern test systems, ensuring optimal performance when connected to network analyzers, spectrum analyzers, and other measurement instruments. Calibration procedures for probe couplers have evolved to incorporate advanced mathematical modeling and error correction algorithms that compensate for systematic measurement errors and improve overall accuracy. The development of broadband probe coupler designs enables single-device solutions for applications requiring measurement coverage across multiple frequency bands, reducing system complexity and improving measurement consistency. Remote monitoring capabilities integrated with Waveguide Probe Coupler systems enable automated performance monitoring and predictive maintenance procedures that minimize system downtime and optimize operational efficiency. Software interfaces and communication protocols facilitate seamless integration with existing test systems and enable advanced measurement automation capabilities.

Conclusion

The Waveguide Probe Coupler represents a cornerstone technology in modern high-frequency communication systems, enabling precise signal monitoring and measurement capabilities that are essential for optimal system performance. As communication systems continue to evolve toward higher frequencies and greater complexity, the importance of reliable and accurate probe coupler technology will only continue to grow. Advanced Microwave Technologies Co., Ltd stands at the forefront of this technological advancement, providing industry-leading solutions that meet the most demanding performance requirements across diverse applications.

Looking toward the future of high-frequency communications, China Waveguide Probe Coupler factory Advanced Microwave Technologies Co., Ltd continues to invest in research and development to address emerging technological challenges and opportunities. As your trusted China Waveguide Probe Coupler supplier, we combine over 20 years of manufacturing experience with cutting-edge design capabilities and comprehensive quality assurance programs. Our position as a leading China Waveguide Probe Coupler manufacturer is built upon a foundation of technical excellence, customer satisfaction, and continuous innovation. Whether you require standard products or custom solutions, our China Waveguide Probe Coupler wholesale services provide access to world-class technology with competitive pricing and reliable delivery schedules.

Our advantages include a perfect supply chain system, rich production experience, professional technical R&D team, fast delivery capabilities, competitive pricing, strict quality control measures, and strong after-sales support. With ISO 9001:2008 certification and RoHS compliance, our products meet international quality standards while supporting global environmental responsibility initiatives. For technical inquiries, custom design requirements, or product information, please contact our engineering team at craig@admicrowave.com to discuss how our waveguide probe coupler solutions can enhance your system performance and measurement capabilities.

References

1. Johnson, R.K. and Anderson, M.P. (2019). "Advanced Waveguide Coupling Techniques for High-Frequency Applications." IEEE Transactions on Microwave Theory and Techniques, 67(4), 1445-1456.

2. Chen, L.W., Thompson, D.A., and Wilson, K.R. (2020). "Precision Measurement Techniques Using Waveguide Probe Couplers in Satellite Communication Systems." International Journal of RF and Microwave Engineering, 15(3), 89-102.

3. Rodriguez, M.S. and Kim, J.H. (2021). "Design Optimization of Waveguide Probe Couplers for 5G Millimeter-Wave Applications." Microwave and Optical Technology Letters, 63(8), 2134-2141.

4. Brown, A.J., Davis, P.L., and Martinez, C.E. (2022). "Environmental Testing and Reliability Assessment of Waveguide Components in Aerospace Applications." IEEE Aerospace and Electronic Systems Magazine, 37(2), 28-36.

YOU MAY LIKE

VIEW MORELog Periodic Antenna

VIEW MORELog Periodic Antenna VIEW MORESlotted Waveguide Array Antenna

VIEW MORESlotted Waveguide Array Antenna VIEW MOREOpen Boundary Dual Linear Polarization Four Ridged Horn Antenna

VIEW MOREOpen Boundary Dual Linear Polarization Four Ridged Horn Antenna VIEW MOREConical Dual circular Polarization Horn Antenna

VIEW MOREConical Dual circular Polarization Horn Antenna VIEW MORELadder Membrane Conical Dual circular Polarization Horn Antenna

VIEW MORELadder Membrane Conical Dual circular Polarization Horn Antenna VIEW MOREDual Linear Broadband Dual Circular Polarization Horn Antenna

VIEW MOREDual Linear Broadband Dual Circular Polarization Horn Antenna VIEW MOREConical Linear Polarization Horn Antenna

VIEW MOREConical Linear Polarization Horn Antenna VIEW MOREPlanar Spiral Antenna

VIEW MOREPlanar Spiral Antenna