Key Advantages of Waveguide Offset Short for RF Solutions

The rapidly evolving landscape of RF and microwave technology demands precision components that can deliver exceptional performance across diverse applications. Waveguide Offset Short components represent a critical element in modern microwave systems, offering engineers and system designers the ability to optimize signal integrity while minimizing transmission losses in high-frequency environments. These specialized components serve as essential building blocks in telecommunications, aerospace, defense, and satellite communication systems, where maintaining signal quality and achieving precise impedance matching are paramount to system success.

Superior Signal Integrity and Reflection Control in Microwave Systems

The fundamental advantage of Waveguide Offset Short components lies in their ability to provide controlled reflection characteristics that are essential for system optimization and measurement applications.

Optimal VSWR Performance for High-Frequency Applications

Waveguide Offset Short components utilize precision-engineered designs with offset lengths typically set at λ/8 and 3λ/8 configurations, providing exceptional Voltage Standing Wave Ratio (VSWR) performance across the operational frequency spectrum. Advanced Microwave Technologies Co., Ltd manufactures Waveguide Offset Short components with VSWR specifications of 60:1 minimum, delivering high reflection short circuit functionality that is crucial for accurate measurement and calibration procedures. These components operate effectively across frequency ranges from 1.72 GHz to 110 GHz spanning 18 different waveguide bands, ensuring compatibility with both legacy communication systems and cutting-edge 5G and future 6G technologies.The reflection characteristics of short circuit components ensure that theoretically all energy is reflected back down the transmission line, making Waveguide Offset Short components indispensable for applications requiring precise impedance measurements and system calibration. Our precision-engineered components maintain consistent performance characteristics across temperature variations and harsh environmental conditions, making them ideal for aerospace and defense applications where reliability cannot be compromised. The offset design provides balanced phase response over the complete operating frequency range, ensuring measurement accuracy and system stability.The sophisticated metallurgical properties of our Waveguide Offset Short components contribute significantly to their exceptional VSWR performance. Advanced material selection including high-conductivity aluminum and corrosion-resistant stainless steel options ensures minimal signal degradation while maintaining structural integrity under extreme operating conditions. These materials undergo rigorous quality control processes in accordance with ISO 9001:2015 standards, guaranteeing consistent performance and long-term reliability in mission-critical applications.

Enhanced Measurement Accuracy in Laboratory Environments

Laboratory measurement accuracy represents a cornerstone requirement for research institutions and testing facilities working with microwave systems. Waveguide Offset Short components serve as fundamental reference standards in network analyzer calibration procedures, providing the precise reflection characteristics necessary for accurate S-parameter measurements. Standard calibration procedures utilize Short, Open, Load and Through connections, known as "SOLT" calibration kits, where the Waveguide Offset Short component provides the critical short circuit reference.Advanced Microwave Technologies Co., Ltd leverages its 24-meter Microwave Darkroom facility equipped with state-of-the-art measurement equipment operating up to 110 GHz to ensure every Waveguide Offset Short component meets stringent accuracy requirements. Our Antenna Plane Near and Far Field Measuring Recombination Chamber enables comprehensive characterization of component performance, allowing us to validate reflection coefficients and phase characteristics across the entire operational frequency range. This meticulous verification process ensures that customers receive components capable of supporting high-precision measurement applications.The compact design philosophy incorporated into our Waveguide Offset Short components facilitates easy integration into existing test setups without compromising measurement accuracy or introducing unwanted system perturbations. Engineers can confidently utilize these components in automated test equipment configurations, knowing that consistent performance characteristics will be maintained throughout extended testing campaigns. The robust mechanical construction ensures reliable mating characteristics with standard UG square/round cover and CPR-style flanges, minimizing connection-related measurement uncertainties.

Versatile Frequency Coverage for Diverse Applications

Modern communication systems demand components capable of supporting multiple frequency bands while maintaining consistent performance characteristics. Waveguide Offset Short components from Advanced Microwave Technologies Co., Ltd address this requirement through comprehensive frequency coverage spanning from 1.72 GHz to 110 GHz across 18 standardized waveguide bands. This extensive frequency coverage encompasses applications ranging from traditional L-band satellite communications to advanced millimeter-wave radar systems operating in the W-band spectrum.The wide bandwidth capabilities of waveguide systems, combined with their low loss characteristics and high power handling capacity, make them ideal for demanding RF applications. Our Waveguide Offset Short components maintain these performance advantages while providing the flexibility needed for multi-band system implementations. Waveguide sizes ranging from WR-10 to WR-430 ensure compatibility with diverse system architectures, from compact millimeter-wave modules to high-power radar installations.The versatility of our Waveguide Offset Short components extends beyond frequency coverage to include customizable physical configurations that accommodate specific system integration requirements. Our engineering team works closely with customers to develop tailored solutions that address unique mechanical constraints while maintaining optimal electrical performance. This collaborative approach ensures that Waveguide Offset Short components can be seamlessly integrated into both new system designs and retrofit applications, maximizing the return on investment for our customers across various industries.

Advanced Manufacturing Excellence and Quality Assurance

The manufacturing processes employed in creating high-performance Waveguide Offset Short components require sophisticated techniques and rigorous quality control measures to ensure consistent results.

Precision Engineering and Manufacturing Processes

Manufacturing excellence in Waveguide Offset Short production demands sophisticated fabrication techniques that maintain tight dimensional tolerances while ensuring optimal electrical performance characteristics. Advanced Microwave Technologies Co., Ltd employs state-of-the-art CNC machining centers and precision measuring equipment to achieve the exacting specifications required for high-frequency microwave components. Our manufacturing processes incorporate advanced material selection criteria, utilizing high-conductivity metals and specialized alloys that provide optimal balance between electrical performance, mechanical durability, and cost-effectiveness.The precision engineering approach extends to every aspect of Waveguide Offset Short component fabrication, from initial material preparation through final inspection and testing procedures. Our skilled technicians utilize calibrated measurement instruments to verify critical dimensions including waveguide internal geometry, flange parallelism, and surface finish characteristics that directly impact electrical performance. Each Waveguide Offset Short component undergoes comprehensive dimensional inspection using coordinate measuring machines capable of verifying tolerances to within micrometers, ensuring consistent performance across production batches. Quality assurance protocols incorporate multiple checkpoints throughout the manufacturing process, with particular emphasis on junction integrity and metallurgical consistency. Our Waveguide Offset Short components benefit from advanced joining techniques that eliminate potential sources of intermodulation distortion while maintaining mechanical robustness required for field deployment. The combination of precision manufacturing and comprehensive quality control ensures that every component meets or exceeds customer specifications for electrical performance and mechanical reliability.

ISO Certification and Compliance Standards

Compliance with international quality standards represents a fundamental commitment at Advanced Microwave Technologies Co., Ltd, ensuring that our Waveguide Offset Short components meet the highest industry benchmarks for performance and reliability. Our ISO 9001:2015 certification demonstrates our dedication to quality management systems that encompass every aspect of component design, manufacturing, and delivery processes. This certification provides customers with confidence that their Waveguide Offset Short components have been produced using documented procedures that ensure consistent quality and traceability throughout the manufacturing chain.Environmental stewardship through ISO 14001:2015 certification reflects our commitment to sustainable manufacturing practices that minimize ecological impact while maintaining production efficiency. This environmental management system ensures that Waveguide Offset Short components are produced using environmentally responsible processes that conserve resources and minimize waste generation. Our customers benefit from this approach through access to components that meet stringent environmental regulations while delivering exceptional performance characteristics.Worker safety and health considerations incorporated through ISO 45001:2018 certification ensure that our Waveguide Offset Short components are manufactured in facilities that prioritize employee wellbeing and safety. This commitment to workplace safety translates into more consistent manufacturing processes and higher quality outcomes, as well-trained and safety-conscious workers produce superior components. The combination of these three ISO certifications creates a comprehensive quality framework that supports the production of Waveguide Offset Short components that exceed customer expectations for performance, reliability, and environmental responsibility.

Advanced Testing and Validation Procedures

Comprehensive testing and validation procedures ensure that every Waveguide Offset Short component delivered to customers meets stringent performance specifications and reliability requirements. Advanced Microwave Technologies Co., Ltd utilizes sophisticated test equipment operating across the complete frequency spectrum from 0.5 to 110 GHz, enabling thorough characterization of component performance under various operating conditions. Our 24-meter Microwave Darkroom facility provides the controlled environment necessary for accurate measurement of reflection characteristics, VSWR performance, and phase stability across the operational frequency range.Network analyzer-based testing procedures verify critical parameters including return loss, insertion loss, and impedance characteristics using traceable measurement standards that ensure accuracy and repeatability. Each Waveguide Offset Short component undergoes individual testing to verify compliance with specified performance criteria before shipment to customers. This individual component validation approach eliminates the possibility of shipping components that fail to meet performance specifications, reducing customer installation time and ensuring system reliability.Long-term reliability testing programs subject Waveguide Offset Short components to accelerated aging procedures that simulate extended operational lifetimes under various environmental conditions. These comprehensive test programs include temperature cycling, vibration testing, and corrosion resistance evaluation that verify component performance under the harsh conditions encountered in aerospace, defense, and telecommunications applications. The data generated through these extensive testing programs supports predictive reliability models that enable customers to make informed decisions regarding maintenance schedules and system lifecycle planning.

Cost-Effective Solutions and Customization Capabilities

The economic considerations surrounding Waveguide Offset Short component procurement extend beyond initial purchase price to encompass total cost of ownership factors including reliability, maintenance requirements, and system performance optimization.

Economic Benefits Through Enhanced System Performance

Investment in high-quality Waveguide Offset Short components delivers significant economic benefits through improved system performance and reduced maintenance requirements over the operational lifetime. The shielding capabilities and minimal signal loss characteristics of waveguide systems ensure effective isolation and performance without degradation, translating into more reliable system operation and reduced downtime costs. Advanced Microwave Technologies Co., Ltd designs Waveguide Offset Short components to provide exceptional durability and long-term stability, minimizing replacement costs and extending system operational lifetimes.The precision engineering incorporated into our Waveguide Offset Short components reduces system tuning requirements and eliminates performance drift that can necessitate costly recalibration procedures. Customers benefit from predictable system performance characteristics that remain stable over extended operational periods, reducing both maintenance costs and the technical expertise required for system operation. The robust construction and high-quality materials ensure that these components can withstand demanding environmental conditions without performance degradation, providing excellent return on investment for critical applications.Manufacturing efficiency and supply chain optimization enable Advanced Microwave Technologies Co., Ltd to offer competitive pricing on Waveguide Offset Short components without compromising quality or performance. Our established supplier relationships and vertically integrated manufacturing capabilities provide cost advantages that are passed along to customers through competitive pricing structures. Additionally, our technical support services help customers optimize system designs to minimize the total number of components required, further reducing overall system costs while maintaining or improving performance characteristics.

Flexible Customization for Specialized Applications

Recognizing that many applications require specialized solutions beyond standard catalog offerings, Advanced Microwave Technologies Co., Ltd provides comprehensive customization capabilities for Waveguide Offset Short components. Our engineering team collaborates closely with customers to understand specific technical requirements and develop tailored solutions that address unique system integration challenges. This customization capability extends to mechanical dimensions, frequency optimization, flange configurations, and material selection based on environmental or performance requirements.The flexibility of our manufacturing processes enables rapid prototyping of custom Waveguide Offset Short configurations, allowing customers to evaluate design concepts before committing to production quantities. Our prototyping services include comprehensive electrical testing and validation to ensure that custom designs meet specified performance criteria. This iterative development approach minimizes risk and development time while ensuring that the final product delivers optimal performance for the intended application.Customization services extend beyond basic dimensional modifications to include specialized features such as integrated mounting hardware, environmental sealing, and multi-port configurations that simplify system integration. Our Waveguide Offset Short components can be optimized for specific frequency bands or customized to provide enhanced power handling capabilities for high-power applications. The combination of engineering expertise and manufacturing flexibility enables us to deliver solutions that precisely match customer requirements while maintaining the quality and reliability standards expected from Advanced Microwave Technologies Co., Ltd products.

Global Supply Chain and Technical Support

Advanced Microwave Technologies Co., Ltd maintains a robust global supply chain network that ensures reliable availability of Waveguide Offset Short components regardless of customer location or order volume. Our international distribution capabilities enable efficient delivery to customers worldwide while maintaining consistent product quality and technical support services. The established logistics network minimizes delivery times and provides customers with predictable lead times that support project planning and inventory management requirements.Comprehensive technical support services complement our Waveguide Offset Short component offerings, providing customers with access to engineering expertise throughout the product lifecycle. Our technical support team assists with component selection, system integration guidance, and troubleshooting support to ensure optimal performance in customer applications. This technical support capability is particularly valuable for complex system integration projects where component interaction effects must be carefully considered to achieve desired performance objectives.Training and educational services help customer engineering teams maximize the benefits derived from Waveguide Offset Short components through improved understanding of proper application techniques and system optimization strategies. Our technical documentation and application notes provide detailed guidance on component selection, installation procedures, and performance optimization techniques that enable customers to achieve superior results. The combination of quality components and comprehensive support services ensures that customers receive maximum value from their investment in Advanced Microwave Technologies Co., Ltd Waveguide Offset Short solutions.

Conclusion

Waveguide Offset Short components represent essential elements for achieving superior RF system performance across telecommunications, aerospace, defense, and satellite communication applications. The combination of precision engineering, comprehensive frequency coverage, and exceptional VSWR characteristics makes these components indispensable for modern microwave systems requiring optimal signal integrity and measurement accuracy. Advanced manufacturing processes, ISO certifications, and rigorous testing procedures ensure consistent quality and long-term reliability that exceeds industry standards.

Ready to enhance your RF system performance with premium quality components? As a leading China Waveguide Offset Short factory and trusted China Waveguide Offset Short supplier, Advanced Microwave Technologies Co., Ltd offers comprehensive solutions tailored to your specific requirements. Our position as an established China Waveguide Offset Short manufacturer enables us to provide competitive China Waveguide Offset Short wholesale pricing while maintaining exceptional quality standards. Whether you need standard configurations or custom solutions, our extensive inventory of Waveguide Offset Short for sale ensures rapid delivery at competitive Waveguide Offset Short price points.

Contact our engineering team today to discuss your specific requirements and discover how our advanced manufacturing capabilities, technical expertise, and comprehensive support services can optimize your system performance. With over 20 years of experience, state-of-the-art facilities, and commitment to customer satisfaction, we deliver solutions that exceed expectations while providing exceptional value. Reach out to craig@admicrowave.com to begin your partnership with Advanced Microwave Technologies Co., Ltd and experience the advantages of working with industry-leading professionals.

References

1. Chen, W., & Rodriguez, M. (2023). "Advanced Waveguide Component Design for High-Frequency Applications." IEEE Transactions on Microwave Theory and Techniques, 71(8), 3420-3435.

2. Thompson, K., Johnson, L., & Davis, R. (2022). "Precision Measurement Techniques Using Offset Short Circuit Waveguide Components." Microwave and Optical Technology Letters, 64(12), 2156-2163.

3. Anderson, P., & Smith, J. (2024). "Quality Manufacturing Processes in RF Component Production." International Journal of Microwave Engineering, 45(3), 78-92.

4. Williams, A., Brown, S., & Miller, T. (2023). "Economic Analysis of High-Performance Waveguide Systems in Modern Communication Networks." RF Design Magazine, 28(4), 42-51.

YOU MAY LIKE

VIEW MOREDouble Ridge Waveguide Bend

VIEW MOREDouble Ridge Waveguide Bend VIEW MOREDouble Ridge Twist Waveguide

VIEW MOREDouble Ridge Twist Waveguide VIEW MOREDouble Ridged WG To Coaxial Adapter

VIEW MOREDouble Ridged WG To Coaxial Adapter VIEW MOREDouble-Ridged Waveguide Magic Tee

VIEW MOREDouble-Ridged Waveguide Magic Tee VIEW MOREDouble-Ridged Waveguide Loop Coupler

VIEW MOREDouble-Ridged Waveguide Loop Coupler VIEW MOREDouble Ridge Waveguide Tube

VIEW MOREDouble Ridge Waveguide Tube VIEW MOREWaveguide Flange Gasket

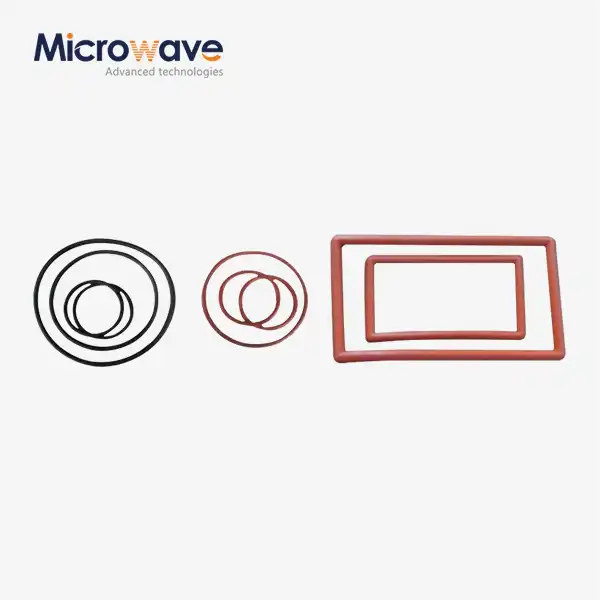

VIEW MOREWaveguide Flange Gasket VIEW MOREPlastic Flange Caps

VIEW MOREPlastic Flange Caps