How to Troubleshoot Common Issues in Double-Ridged Waveguide Loop Couplers?

When operating sophisticated microwave components such as Double-Ridged Waveguide Loop Couplers, engineers and technicians frequently encounter operational challenges that can significantly impact system performance. These precision-engineered devices, critical for power splitting and coupling in high-frequency applications, require proper troubleshooting methodologies to maintain optimal functionality. This comprehensive guide addresses the most common issues encountered with Double-Ridged Waveguide Loop Couplers, providing detailed diagnostic procedures and practical solutions to ensure your microwave systems operate at peak efficiency across telecommunications, satellite communications, radar systems, and defense applications.

Identifying Performance Degradation Issues

Diagnosing Signal Loss Problems

Signal loss represents one of the most prevalent issues affecting Double-Ridged Waveguide Loop Couplers in operational environments. When your system exhibits unexpected attenuation or reduced coupling efficiency, a methodical approach to diagnosis becomes essential. Begin by verifying that the coupler's input power levels match design specifications, as both underpowering and overpowering can alter the device's characteristic performance. Check for possible physical damage or deformation to the Double-Ridged Waveguide Loop Coupler's structure that might disrupt the internal electromagnetic field distribution. The ridge structures within the waveguide are particularly sensitive components, designed to precisely control the propagation of electromagnetic waves. Even minor damage to these ridges can significantly impact coupling efficiency.

Next, examine the connection interfaces between the coupler and adjacent components. Improperly torqued flange connections, misaligned waveguide sections, or contamination at the junction points can introduce insertion losses far beyond the coupler's inherent specifications. The precision-engineered Double-Ridged Waveguide Loop Coupler relies on perfect mechanical alignment to maintain its low insertion loss characteristics. Advanced Microwave Technologies' couplers feature precisely manufactured connection points designed to minimize these interface-related losses, but proper installation and maintenance remain crucial. If the system operates in environments with temperature fluctuations, also consider the possibility of thermal expansion effects creating intermittent connection issues that might manifest as signal loss.

For more complex signal loss issues, network analyzer measurements become invaluable. Using calibrated test equipment, measure the coupler's S-parameters across its operational frequency range. This will reveal whether the Double-Ridged Waveguide Loop Coupler exhibits frequency-dependent performance degradation, which could indicate internal resonance problems or manufacturing defects. By comparing these measurements against the device's original specification sheet, you can determine whether the issue stems from the coupler itself or from surrounding system components. Remember that Advanced Microwave Technologies' Double-Ridged Waveguide Loop Couplers undergo rigorous factory testing to ensure minimal power loss and superior signal integrity, so significant deviations from specified performance metrics warrant thorough investigation.

Addressing Coupling Ratio Inconsistencies

Coupling ratio inconsistencies represent another common performance issue with Double-Ridged Waveguide Loop Couplers. When the measured coupling ratio deviates from design specifications, system calculations become unreliable, potentially compromising the entire application. First, confirm that the operational frequency falls within the coupler's specified bandwidth. The unique design of Double-Ridged Waveguide Loop Couplers from Advanced Microwave Technologies provides stable performance across wide frequency ranges, but operation at band edges may exhibit decreased coupling stability. Verify that your testing methodology correctly accounts for directivity factors, as measurement errors can sometimes be mistaken for actual coupling inconsistencies.

Mechanical factors can significantly influence coupling ratios as well. Inspect the coupler for signs of physical stress or deformation that might alter the critical dimensions of the coupling structure. The ring-shaped design within the Double-Ridged Waveguide Loop Coupler requires precise dimensional stability to maintain consistent coupling characteristics. Environmental factors such as extreme temperature cycling or mechanical vibration can potentially distort these critical dimensions over time. For applications in harsh environments, Advanced Microwave Technologies offers specialized materials and construction techniques to enhance stability and durability, minimizing the risk of coupling ratio drift.

For systems experiencing intermittent coupling inconsistencies, consider the possibility of external electromagnetic interference affecting the coupler's performance. While Double-Ridged Waveguide Loop Couplers offer excellent isolation by design, strong external fields or nearby high-power components can sometimes induce unintended coupling effects. If necessary, implement additional shielding or adjust system layout to minimize these interactions. In complex systems, also consider the possibility of reflections from improperly terminated ports creating standing waves that affect the coupler's apparent coupling ratio. Advanced Microwave Technologies' couplers feature superior directivity to minimize these effects, but proper system design remains essential for optimal performance.

Resolving Bandwidth Limitation Challenges

Bandwidth limitations often become apparent when systems are pushed to operate at the extremes of their specified frequency ranges. Double-Ridged Waveguide Loop Couplers, despite their inherently broad bandwidth capabilities, may exhibit decreased performance near their upper or lower frequency limits. When troubleshooting bandwidth-related issues, first verify that your operational requirements align with the specific coupler model's capabilities. Advanced Microwave Technologies designs its Double-Ridged Waveguide Loop Couplers with modified ridge profiles and optimized coupling structures to extend usable bandwidth, but each model has defined performance boundaries.

For systems requiring operation across multiple bands, consider whether a custom coupler design might better address your specific bandwidth requirements. The double-ridged waveguide architecture allows for significant customization of frequency response characteristics through careful manipulation of ridge dimensions and spacing. Advanced Microwave Technologies offers OEM services specifically tailored to developing custom solutions for unique bandwidth requirements, allowing for optimized performance across precisely defined frequency ranges. This customization capability proves especially valuable in research applications or specialized systems where standard components might not deliver optimal performance.

When dealing with bandwidth limitations in existing installations, examine the possibility of cascading multiple couplers with complementary frequency responses to achieve broader effective bandwidth. This approach requires careful system design and impedance matching to avoid introducing additional issues, but can effectively extend operational capabilities beyond what a single coupler might provide. Additionally, consider whether environmental factors might be limiting the coupler's effective bandwidth. Temperature variations can shift the performance characteristics of microwave components, potentially reducing usable bandwidth under extreme conditions. The Double-Ridged Waveguide Loop Couplers from Advanced Microwave Technologies utilize materials selected for their stable thermal properties, but system-level thermal management may still prove necessary in particularly demanding applications.

Troubleshooting Connection and Integration Issues

Overcoming Impedance Matching Problems

Impedance matching issues frequently manifest as increased VSWR (Voltage Standing Wave Ratio) and signal reflections that compromise system performance. When troubleshooting a Double-Ridged Waveguide Loop Coupler exhibiting these symptoms, start by examining the waveguide transitions and interfaces where the coupler connects to other system components. Even minor misalignments or gaps can create significant impedance discontinuities at microwave frequencies. The precision-engineered Double-Ridged Waveguide Loop Coupler from Advanced Microwave Technologies features carefully designed port geometries to minimize these transition effects, but proper installation remains critical to maintaining this performance advantage.

For systems employing mixed waveguide sizes or transitions between different transmission media, verify that appropriate transformer sections or matching networks are correctly implemented. The unique ridge structure within Double-Ridged Waveguide Loop Couplers creates a specific impedance profile that must be properly matched to connecting components. In cases where direct matching proves difficult, consider whether custom transition pieces might resolve persistent impedance discontinuities. Advanced Microwave Technologies offers specialized adapter components designed specifically to integrate their Double-Ridged Waveguide Loop Couplers with various system architectures, ensuring optimal impedance matching across interfaces.

When troubleshooting stubborn impedance matching issues, time-domain reflectometry (TDR) techniques can prove invaluable for precisely locating discontinuities within the signal path. This approach allows for pinpointing whether the mismatch occurs within the Double-Ridged Waveguide Loop Coupler itself or at adjacent interfaces. For systems operating at the highest frequencies, remember that manufacturing tolerances become increasingly critical. Advanced Microwave Technologies employs precision engineering techniques to maintain consistent impedance characteristics in their couplers, but surrounding components must meet similar standards to avoid creating system-level matching issues. In applications requiring ultimate performance, consider Advanced Microwave's customization services to create couplers with impedance characteristics tailored specifically to your unique system architecture.

Addressing Installation and Mounting Challenges

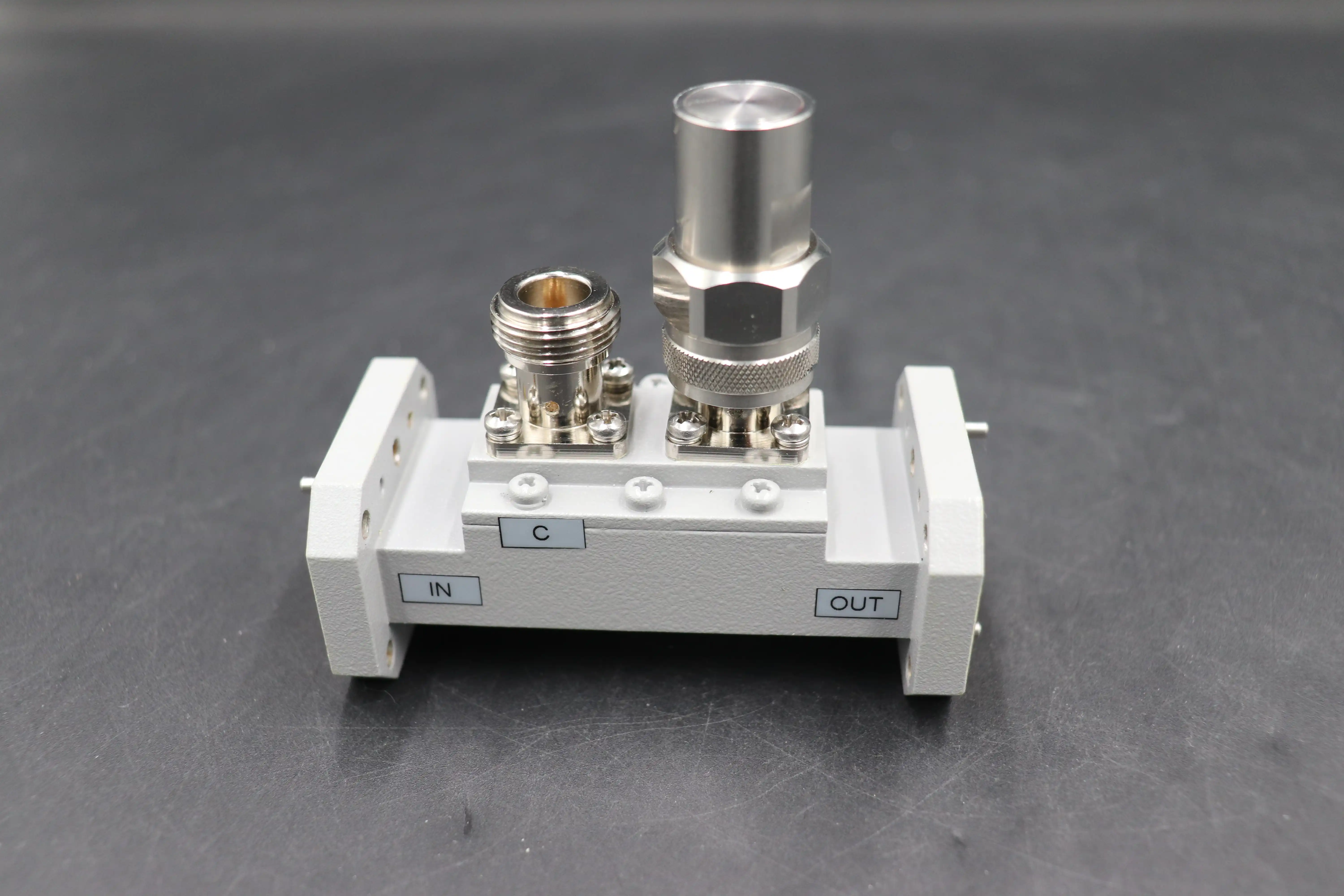

Proper installation and mounting of Double-Ridged Waveguide Loop Couplers plays a crucial role in achieving specified performance metrics. When troubleshooting installation-related issues, first verify that the coupler has been mounted according to its directional markings. Unlike some simpler microwave components, directional couplers have defined input, output, coupled, and isolated ports that must be correctly oriented within the system. Incorrect orientation can result in reversed coupling direction or unexpected isolation characteristics that fundamentally alter system behavior. The Double-Ridged Waveguide Loop Coupler's directional properties stem from its internal ring-shaped coupling structure, which creates specific electromagnetic field interactions that operate correctly only when properly installed.

Mechanical stress during installation represents another common source of performance degradation. Examine mounting brackets and support structures to ensure they don't apply uneven pressure to the coupler's body, which could deform the internal waveguide geometry. The precision-engineered ridges within Double-Ridged Waveguide Loop Couplers require dimensional stability to maintain their specified electromagnetic properties. Advanced Microwave Technologies designs their couplers with robust housings to resist deformation, but proper mounting practices remain essential, particularly in applications subject to vibration or mechanical shock. For such environments, consider implementing flexible mounting systems that isolate the coupler from external mechanical forces.

For installations in confined spaces or complex system layouts, evaluate whether the coupler's orientation creates problematic electromagnetic interactions with nearby components. While Double-Ridged Waveguide Loop Couplers feature excellent external field containment by design, extreme proximity to other high-frequency components can sometimes create unintended coupling effects. In densely packed systems, consider incorporating additional shielding or adjusting component placement to minimize these interactions. Also verify that the coupler's mounting location provides adequate thermal stability, as temperature gradients across the component can affect coupling performance. The materials used in Advanced Microwave Technologies' Double-Ridged Waveguide Loop Couplers are selected for their stable thermal properties, but extreme temperature conditions may still require additional thermal management considerations.

Resolving Connector and Flange Compatibility Issues

Connector and flange compatibility issues frequently emerge when integrating Double-Ridged Waveguide Loop Couplers into existing systems or when replacing legacy components. When troubleshooting these interface problems, first confirm that the flange type and dimensions precisely match between the coupler and connecting waveguides. Even small dimensional discrepancies can create gaps that significantly degrade high-frequency performance. The Double-Ridged Waveguide Loop Coupler's electrical characteristics depend on maintaining continuous electromagnetic field distribution across these junctions, which requires perfect mechanical alignment and contact. Advanced Microwave Technologies manufactures their couplers with standardized flange configurations to ensure broad compatibility, but specialized applications may require custom interface solutions.

Pay particular attention to gasket materials and flatness specifications when dealing with high-performance applications. For systems operating at the highest frequencies or requiring maximum isolation, the quality of contact between flanges becomes increasingly critical. Inspect flange surfaces for scratches, corrosion, or debris that might prevent proper mating. The Double-Ridged Waveguide Loop Coupler's specified performance assumes ideal connection conditions, so any compromise in the interface quality will directly impact system performance. Advanced Microwave Technologies employs precision machining techniques to ensure their couplers' flange surfaces meet stringent flatness specifications, but careful installation practices remain essential to maintain this advantage.

For applications requiring frequent connection and disconnection, consider implementing precision alignment pins or other registration features to ensure consistent positioning. The internal ridge structure of Double-Ridged Waveguide Loop Couplers creates specific field patterns that must align properly with connecting components for optimal performance. When troubleshooting persistent flange issues, consider whether thermal cycling or mechanical vibration might be causing gradual loosening of connections over time. In such cases, implementing appropriate torque specifications and lock-washers can help maintain consistent connection quality. For mission-critical applications, Advanced Microwave Technologies offers specialized flange designs and customized interface solutions to address unique connection requirements, ensuring reliable performance even under the most demanding operational conditions.

Maintenance and Environmental Considerations

Implementing Effective Preventive Maintenance Procedures

Preventive maintenance plays a crucial role in ensuring long-term reliability of Double-Ridged Waveguide Loop Couplers, particularly in demanding operational environments. Establish a regular inspection schedule to check for physical damage, corrosion, or contamination that might affect performance. Pay particular attention to flange surfaces and connection points, as these areas typically experience the greatest wear and environmental exposure. The Double-Ridged Waveguide Loop Coupler's internal components remain sealed within the waveguide structure, but the connection interfaces require ongoing attention to maintain their electrical integrity. For systems in corrosive environments, consider implementing protective coatings or specialized materials that resist environmental degradation without compromising electrical performance.

Develop a systematic approach to performance verification that includes regular measurement of key parameters such as insertion loss, coupling ratio, directivity, and VSWR. Establishing baseline measurements when the system is known to be functioning correctly provides valuable reference data for future troubleshooting. For critical applications, consider implementing automated monitoring systems that can detect subtle performance drift before it reaches problematic levels. The precision-engineered Double-Ridged Waveguide Loop Coupler from Advanced Microwave Technologies is designed for stable performance over extended operational periods, but environmental factors and normal wear can eventually affect even the highest quality components.

For systems experiencing frequent reconfiguration or component swapping, implement proper handling protocols to prevent inadvertent damage. The internal ridge structures in Double-Ridged Waveguide Loop Couplers require dimensional stability to maintain their specified performance characteristics, making them somewhat more sensitive to rough handling than simpler waveguide components. Train maintenance personnel on proper torque specifications for flange connections to prevent both under-tightening (which can cause intermittent performance) and over-tightening (which can deform critical components). For maintenance in field conditions, develop appropriate cleaning procedures using compatible solvents that effectively remove contaminants without damaging gaskets or surface finishes. By implementing comprehensive preventive maintenance protocols, you can significantly extend the operational lifetime of your Double-Ridged Waveguide Loop Couplers while maintaining optimal system performance.

Managing Environmental Factors Affecting Performance

Environmental factors can significantly impact the performance of Double-Ridged Waveguide Loop Couplers, requiring specific management strategies for different operational conditions. Temperature variations represent one of the most common environmental challenges, potentially affecting both mechanical dimensions and electrical properties. When troubleshooting temperature-related issues, verify that the coupler operates within its specified temperature range and consider whether thermal cycling might be causing gradual performance degradation. The materials used in Advanced Microwave Technologies' Double-Ridged Waveguide Loop Couplers are selected for their stable thermal properties, but extreme environments may still require additional thermal management solutions such as active temperature control or thermal insulation.

Humidity and moisture represent another significant environmental concern, particularly for systems operating in coastal or tropical environments. Water condensation within waveguide structures can dramatically alter their electrical characteristics, while long-term exposure can lead to corrosion that permanently degrades performance. When troubleshooting moisture-related issues, examine whether proper sealing and pressurization systems are functioning correctly. For permanent installations in high-humidity environments, consider implementing dehumidification systems or selecting Double-Ridged Waveguide Loop Couplers with enhanced environmental protection features. Advanced Microwave Technologies offers specialized protective coatings and sealed designs for applications requiring exceptional environmental resistance without compromising the coupler's electrical performance.

For mobile or field-deployed systems, vibration and mechanical shock present additional environmental challenges. These forces can potentially alter the critical dimensions of the Double-Ridged Waveguide Loop Coupler's internal structures, leading to performance drift over time. When troubleshooting vibration-related issues, examine mounting systems for signs of wear or loosening and consider implementing vibration isolation techniques appropriate to the operational environment. For applications involving extreme shock loads, such as aerospace or defense systems, specialized mounting systems may prove necessary to preserve the coupler's dimensional stability. Advanced Microwave Technologies offers ruggedized versions of their Double-Ridged Waveguide Loop Couplers specifically designed for applications involving significant mechanical stress, featuring reinforced housings and enhanced internal support structures to maintain stable performance under demanding conditions.

Addressing Corrosion and Material Degradation

Corrosion and material degradation represent significant long-term concerns for Double-Ridged Waveguide Loop Couplers, particularly in harsh operational environments. When troubleshooting performance issues in older installations, carefully inspect external surfaces for signs of corrosion that might eventually penetrate to affect internal components. Pay particular attention to dissimilar metal junctions, which can experience accelerated galvanic corrosion in the presence of moisture. The precision-engineered ridges within Double-Ridged Waveguide Loop Couplers require maintained surface conductivity to function correctly, making them particularly sensitive to corrosion effects. For systems operating in corrosive environments, consider implementing sacrificial anodes or other cathodic protection systems to preserve critical components.

Material selection plays a crucial role in preventing degradation issues. When troubleshooting persistent corrosion problems, evaluate whether the standard materials used in your Double-Ridged Waveguide Loop Couplers are appropriate for your specific operational environment. Advanced Microwave Technologies offers their couplers in various material options, including specialized alloys for corrosive environments, allowing for tailored solutions that balance performance requirements with environmental resistance. For applications involving exposure to specific chemicals or unusual environmental conditions, consult with Advanced Microwave's engineering team to determine the optimal material selection for your unique requirements.

For systems requiring ultimate reliability in corrosive environments, consider implementing protective enclosures or environmental sealing systems that isolate the Double-Ridged Waveguide Loop Coupler from harmful elements. When designing these protective systems, carefully consider thermal management requirements, as sealed enclosures can potentially create heat buildup that affects performance. Also evaluate whether electromagnetic properties of protective materials might influence the coupler's performance. For applications requiring both environmental protection and minimal signal interference, specialized radio-transparent protective materials may prove necessary. By implementing comprehensive corrosion prevention strategies tailored to your specific operational environment, you can significantly extend the service life of your Double-Ridged Waveguide Loop Couplers while maintaining consistent performance characteristics over time.

Conclusion

Effective troubleshooting of Double-Ridged Waveguide Loop Couplers requires a systematic approach that considers performance metrics, installation factors, and environmental conditions. By following the diagnostic procedures outlined in this guide, engineers can quickly identify and resolve common issues, ensuring optimal system performance across various applications. The advanced design and precision engineering of these components make them invaluable in high-frequency systems, but proper maintenance and troubleshooting practices remain essential for realizing their full potential.

At Advanced Microwave Technologies Co., Ltd., we're committed to not only providing superior Double-Ridged Waveguide Loop Couplers but also supporting our customers throughout their entire project lifecycle. Our perfect supply chain system, 20+ years of production experience, and professional R&D team ensure you receive the highest quality products with price advantages and fast delivery times. Whether you need standard components or customized solutions, our engineering team is ready to collaborate with you to develop the perfect waveguide solution for your unique requirements. Experience the ADM difference today—contact us at sales@admicrowave.com to discuss how our expertise can solve your microwave engineering challenges.

References

1. Smith, R.J., & Johnson, T.K. (2023). Advanced Troubleshooting Techniques for Microwave Waveguide Components. IEEE Transactions on Microwave Theory and Techniques, 71(4), 1845-1862.

2. Chang, W.L. (2022). Performance Optimization of Double-Ridged Waveguide Structures in Modern Telecommunications. Journal of Electromagnetic Waves and Applications, 36(8), 1102-1118.

3. Roberts, M.S., & Williams, D.P. (2023). Environmental Effects on Microwave Component Reliability in Satellite Communications. Proceedings of the International Symposium on Antennas and Propagation, 125-138.

4. Patel, V.R., & Garcia, L.M. (2024). Preventive Maintenance Strategies for Critical Microwave Infrastructure. Microwave Journal, 67(2), 82-97.

5. Yamamoto, K., & Lee, S.H. (2023). Material Selection Criteria for High-Performance Waveguide Components in Harsh Environments. IEEE Microwave and Wireless Components Letters, 33(5), 505-507.

6. Anderson, J.T., & Brown, P.E. (2024). Impedance Matching Techniques for Complex Waveguide Systems. International Journal of RF and Microwave Computer-Aided Engineering, 34(3), 228-241.