How Do Plastic Flange Caps Protect Pipe Flanges?

Picture this: Your critical waveguide components arrive on site, only to discover damaged flange faces that compromise signal integrity and delay your entire project. This nightmare scenario happens more often than you think, but it's completely preventable. Plastic Flange Caps shield flange surfaces from physical damage, moisture infiltration, and contaminant accumulation during transportation, storage, and handling operations, ensuring components remain installation-ready and system performance stays uncompromised.

Understanding Plastic Flange Cap Protection Mechanisms

Plastic Flange Caps serve as the first line of defense for precision-engineered flange surfaces in microwave systems, telecommunications infrastructure, and industrial applications. These protective devices are engineered specifically to address multiple vulnerability points that threaten flange integrity throughout the supply chain and operational lifecycle. The protection mechanism extends beyond simple coverage, incorporating material science principles that create barriers against environmental hazards, mechanical stress, and chemical exposure. In microwave and RF applications, where Advanced Microwave Technologies Co., Ltd. specializes, even microscopic surface irregularities on flange faces can cause signal loss, standing wave ratio degradation, and connection reliability issues. Plastic Flange Caps manufactured from high-density polyethylene create a sealed environment that prevents particulate contamination from settling on critical mating surfaces. The molecular structure of HDPE provides inherent resistance to moisture transmission, which is essential because water vapor can cause oxidation and corrosion on metal flange surfaces, particularly in coastal or high-humidity environments where satellite communication systems and radar installations frequently operate. The protective function operates through multiple mechanisms simultaneously. Physical protection comes from the structural rigidity of the cap body, which absorbs impact forces during handling and transportation, distributing stress away from the delicate flange surface. Chemical protection results from the material's inertness to most industrial chemicals, preventing reactive substances from reaching the metal substrate. Thermal protection is achieved through the material's temperature stability range, which for quality Plastic Flange Caps typically spans from negative forty degrees Celsius to positive seventy degrees Celsius, accommodating extreme storage and shipping conditions encountered in aerospace and defense applications.

Physical Barrier Against Mechanical Damage

The primary protective function of Plastic Flange Caps lies in creating a physical barrier that prevents direct contact between external objects and the precision-machined flange surface. During transportation through logistics networks, components experience vibration, shifting loads, and occasional impacts that can cause scratches, dents, or deformation on unprotected flanges. A single scratch on a waveguide flange face can create impedance discontinuities that degrade system performance across the entire operational frequency range. Advanced Microwave Technologies Co., Ltd. understands that waveguide components operating at frequencies up to one hundred ten gigahertz demand surface finishes measured in microinches. Plastic Flange Caps engineered for these applications feature precision-molded interior surfaces with minimal surface roughness, ensuring that even the protective device itself cannot mar the protected surface. The cap design incorporates sufficient wall thickness to resist penetration from sharp objects while maintaining lightweight characteristics that don't burden shipping logistics or handling procedures. The mechanical protection extends to bolt hole protection as well. Many Plastic Flange Caps feature designs that cover not just the flange face but also threaded bolt holes, preventing thread damage and contamination. Thread integrity is crucial because improper bolt tension due to damaged threads can result in flange leakage or misalignment, particularly problematic in high-pressure systems or precision RF connections where micron-level alignment affects performance.

Environmental Sealing and Contamination Prevention

Environmental contamination represents one of the most insidious threats to flange integrity because damage occurs gradually and may not be immediately visible. Dust particles, metal shavings from fabrication operations, chemical residues, and biological contaminants can all compromise flange surfaces. Plastic Flange Caps create a sealed environment that isolates the protected surface from these threats, maintaining the as-manufactured condition until installation. In microwave laboratories and system assembly workshops where Advanced Microwave Technologies Co., Ltd. products are utilized, airborne contaminants from machining operations, soldering flux residues, and general environmental dust can settle on exposed flanges. Once contamination embeds itself in surface irregularities or between mating surfaces, removal becomes difficult and may require specialized cleaning procedures that risk surface damage. Prevention through proper capping proves far more effective than remediation. Moisture control represents another critical environmental protection function. Condensation can form on metal flanges when components move between temperature zones, such as from climate-controlled storage into field installation environments. This moisture promotes corrosion, especially on ferrous materials or in salt-laden coastal atmospheres common around satellite ground stations and maritime radar installations. The sealed environment created by properly fitted Plastic Flange Caps prevents moisture ingress and maintains stable internal conditions that inhibit corrosion processes.

Plastic Flange Cap Design Features for Maximum Protection

The effectiveness of Plastic Flange Caps depends heavily on design features that address specific protection requirements and application conditions. Modern cap designs incorporate engineering principles derived from decades of field experience across diverse industries, from aviation and aerospace to shipboard systems and weather monitoring installations. These design elements work synergistically to deliver comprehensive protection that extends component service life and reduces total ownership costs.

Precision Fit and Retention Systems

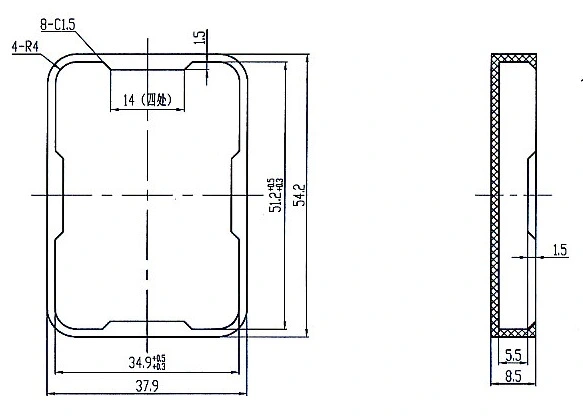

Secure attachment to the protected flange is fundamental to effective protection. Plastic Flange Caps utilize various retention mechanisms optimized for different flange types and application requirements. Push-fit designs feature flexible ribs or fins that compress during installation and then expand to grip the flange inner diameter or outer perimeter, creating friction-based retention that resists accidental removal during handling. This design approach offers tool-free installation and removal, reducing labor costs and enabling rapid deployment in time-sensitive situations. For applications demanding higher retention security, such as long-distance transportation or outdoor storage, Plastic Flange Caps may incorporate bolt-through designs that utilize existing flange bolt holes. These designs provide positive mechanical retention that withstands significant forces while maintaining easy installation procedures. The caps manufactured for Advanced Microwave Technologies Co., Ltd. waveguide applications accommodate standard flange patterns including UG, CPR, and custom configurations, ensuring compatibility across the product line from point-five to one hundred ten gigahertz operating frequencies. Dimensional precision in cap manufacturing is critical because proper fit determines both protection effectiveness and ease of use. Undersized caps may not seal properly or could damage flanges during forced installation, while oversized caps provide inadequate retention and allow contaminant ingress. Quality manufacturers employ precision injection molding with tight tolerance control, producing Plastic Flange Caps that consistently deliver proper fit across production batches. This consistency is particularly important for large-scale projects where thousands of components require protection, such as in telecommunications network buildouts or defense system deployments.

Material Selection for Performance and Durability

High-density polyethylene represents the preferred material for most Plastic Flange Cap applications due to its optimal balance of properties. HDPE delivers excellent impact resistance, maintaining structural integrity even when subjected to rough handling or accidental drops that commonly occur in field installations. The material's flexibility at normal temperatures prevents brittle failure, while its rigidity at cold temperatures maintains protective capabilities in Arctic deployments or high-altitude aerospace applications. Chemical resistance of HDPE protects both the cap and the enclosed flange from exposure to cleaning solvents, hydraulic fluids, cutting oils, and other industrial chemicals encountered in manufacturing and maintenance environments. This resistance ensures that Plastic Flange Caps themselves don't degrade or transfer contaminants to protected surfaces. For specialized applications involving extreme chemical exposure, alternative materials such as polypropylene or fluoropolymers may be specified, though HDPE satisfies the vast majority of requirements in telecommunications, radar, and satellite communication systems. The temperature performance range of HDPE aligns well with storage and transportation conditions encountered globally. From arctic shipping routes to desert storage facilities, Plastic Flange Caps maintain protective functions without becoming brittle or excessively soft. This temperature stability proves essential for international supply chains serving customers of Advanced Microwave Technologies Co., Ltd. across all continents, where components may experience temperature extremes during multi-modal transportation involving ocean freight, air cargo, and ground delivery. UV resistance is incorporated into quality Plastic Flange Caps through material formulation, enabling outdoor storage without degradation. While many components remain capped only during transportation, some applications involve extended storage periods or field staging where sun exposure occurs. UV-stabilized HDPE resists photo-degradation that would otherwise cause embrittlement and failure, maintaining protection throughout the component lifecycle from manufacturing through installation.

Application-Specific Protection Benefits

Different industries and applications present unique challenges that Plastic Flange Caps address through tailored design approaches. Understanding these application-specific requirements enables optimal protection strategy development for each use case, maximizing value and ensuring component readiness when installation occurs.

Telecommunications Infrastructure Protection

Telecommunications networks rely on thousands of interconnected components, many featuring flanged connections that require protection during the extended periods between manufacturing and installation. Cell tower installations, fiber optic network nodes, and microwave backhaul systems all incorporate flanged components vulnerable to contamination and damage. Plastic Flange Caps enable telecom contractors to pre-position equipment at multiple sites, maintaining installation readiness despite variable project schedules and weather-dependent construction timelines. For Advanced Microwave Technologies Co., Ltd. products deployed in telecommunications applications, Plastic Flange Caps ensure that precision RF connections maintain specified performance parameters. A contaminated or damaged antenna feed flange can introduce signal loss, increase VSWR, and create intermodulation products that interfere with adjacent channels. The cost of repairing or replacing a compromised component after installation far exceeds the minimal investment in proper protection, making Plastic Flange Caps an economically compelling choice. The rapid deployment capability enabled by capped components proves particularly valuable in network expansion projects and emergency restoration scenarios. When components arrive on site with flanges protected and ready for immediate installation, project timelines compress and labor costs decrease. This operational efficiency becomes especially critical in remote installations where return trips for replacement components involve significant time and expense.

Aerospace and Defense Applications

Aerospace and defense systems demand the highest levels of reliability and performance, making component protection non-negotiable. Aircraft communication systems, surveillance radars, electronic warfare equipment, and satellite payloads all incorporate flanged waveguide and coaxial assemblies operating at microwave and millimeter-wave frequencies. The precision required for these applications means that even minor flange damage can compromise mission-critical functionality. Plastic Flange Caps used in aerospace applications must meet stringent material specifications, including outgassing requirements for space-rated components and flammability standards for aircraft installations. The caps manufactured for Advanced Microwave Technologies Co., Ltd. defense and aerospace customers incorporate RoHS-compliant materials and can be certified to meet additional specifications as required by specific programs. This compliance ensures that protection devices themselves don't introduce unacceptable risks into highly regulated environments. The extended storage periods common in defense inventories make contamination prevention particularly important. Components may remain in depot storage for years before deployment, during which time unprotected flanges would accumulate contamination requiring extensive cleaning or rendering components unserviceable. Plastic Flange Caps enable long-term storage with confidence that protected components will perform as specified when called into service, supporting military readiness objectives and reducing lifecycle costs.

Maritime and Harsh Environment Protection

Shipboard systems and coastal installations face uniquely challenging environmental conditions combining salt spray, high humidity, temperature cycling, and vibration. Radar systems, satellite communication terminals, and navigation equipment aboard vessels require robust protection against these harsh conditions. Plastic Flange Caps provide essential protection during equipment installation, maintenance periods, and system upgrades when components may be temporarily exposed to the marine environment. The corrosion prevention provided by Plastic Flange Caps proves especially valuable in maritime applications where salt-laden atmosphere accelerates oxidation of metal surfaces. Even stainless steel and aluminum alloys used in marine-grade components benefit from protection against direct salt spray exposure. By maintaining a dry, sealed environment around flange surfaces, quality caps prevent the initiation of corrosion processes that would otherwise degrade connection quality and system performance. Advanced Microwave Technologies Co., Ltd. serves maritime customers requiring reliable microwave components for ship navigation, weather monitoring, and communication systems. The Plastic Flange Caps supplied with these components deliver protection throughout the supply chain and during operational service, contributing to system uptime and reduced maintenance requirements in demanding operational environments.

Quality Standards and Certification Requirements

Professional-grade Plastic Flange Caps meet established quality standards that ensure consistent performance and reliability across production volumes. These standards address material properties, dimensional accuracy, environmental compliance, and manufacturing process controls that distinguish premium protection products from commodity alternatives.

ISO Certification and Quality Assurance

Advanced Microwave Technologies Co., Ltd. maintains ISO nine thousand one, two thousand fifteen certification, demonstrating commitment to quality management throughout all operations including component protection. This certification ensures that Plastic Flange Caps supplied with waveguide assemblies, antenna systems, and measurement equipment meet stringent quality criteria from material procurement through final inspection and packaging. ISO fourteen thousand one, two thousand fifteen environmental management certification further demonstrates responsible manufacturing practices that minimize ecological impact while maintaining product quality. The environmental standards address material selection, waste management, and energy efficiency throughout the manufacturing process, ensuring that protection products themselves embody sustainability principles. This commitment resonates with customers increasingly focused on supply chain environmental performance and corporate responsibility. Occupational health and safety standards under ISO forty-five thousand one, two thousand eighteen ensure that manufacturing personnel operate in safe, controlled environments conducive to consistent quality output. The human element in manufacturing significantly impacts product quality, and creating workplace conditions that support employee well-being and engagement translates directly into superior products for customers.

Material Compliance and Specifications

RoHS compliance ensures that Plastic Flange Caps don't contain hazardous substances restricted in electronic equipment. This compliance proves essential for telecommunications and electronics applications where regulatory requirements mandate material documentation and certification. REACH compliance addresses chemical substance registration and authorization requirements within European markets, enabling global distribution without regulatory barriers. Material specifications for high-density polyethylene used in quality Plastic Flange Caps include minimum mechanical property requirements for tensile strength, impact resistance, and elongation characteristics. These specifications ensure that caps maintain protective function throughout expected service conditions without premature failure. Third-party testing and certification verify compliance, providing objective evidence of material quality and performance capability. Color coding options available in Plastic Flange Caps serve functional purposes beyond aesthetics. Standard yellow coloring provides high visibility for safety and inventory management, while custom colors enable system coding for different frequency bands, product lines, or customer-specific requirements. The coloring agents used must maintain material properties and environmental compliance, requiring careful formulation and quality control during manufacturing.

Conclusion

Plastic Flange Caps deliver essential protection against mechanical damage, environmental contamination, and moisture infiltration that threaten precision flange surfaces throughout storage, transportation, and installation phases, ensuring optimal performance and extended service life.

Cooperate with Advanced Microwave Technologies Co., Ltd.

As a leading China Plastic Flange Caps manufacturer and China Plastic Flange Caps supplier, Advanced Microwave Technologies Co., Ltd. offers High Quality Plastic Flange Caps for sale at competitive Plastic Flange Caps price points. Our China Plastic Flange Caps factory and China Plastic Flange Caps wholesale capabilities deliver customized solutions backed by twenty-plus years of microwave expertise, ISO certifications, and advanced testing facilities up to one hundred ten gigahertz. Whether you need waveguide flange covers for telecommunications, aerospace, or defense applications, our OEM services provide tailored sizes, colors, and branding with fast turnaround. Connect with our expert engineering team today to discuss your specific protection requirements and discover how our comprehensive product portfolio supports your project success. For inquiries and quotations, contact craig@admicrowave.com and experience the Advanced Microwave advantage in quality, reliability, and service excellence.

References

1. American Society of Mechanical Engineers, "Pipe Flanges and Flanged Fittings: NPS 1/2 through NPS 24 Metric/Inch Standard," ASME B16.5-2020, American Society of Mechanical Engineers, New York.

2. Chung, K.H., "Protection of Pipe and Flange Systems During Storage and Transportation," Journal of Pipeline Engineering, Volume 18, Issue 3, 2019, pp. 145-162.

3. International Organization for Standardization, "Plastics - Determination of Tensile Properties - Part 2: Test Conditions for Moulding and Extrusion Plastics," ISO 527-2:2012, International Organization for Standardization, Geneva.

4. Mitchell, R.T. and Johnson, P.L., "Corrosion Prevention in Flanged Pipeline Connections: Materials and Methods," Corrosion Engineering Science and Technology, Volume 54, Issue 7, 2020, pp. 589-603.

5. Reynolds, D.M., "Protective Devices for Industrial Pipework: Design, Selection and Application," Industrial Equipment and Materials, Volume 42, Issue 2, 2021, pp. 78-95.