How Do High-Quality Materials Enhance the Durability of Circular Waveguide To Coaxial Adapters?

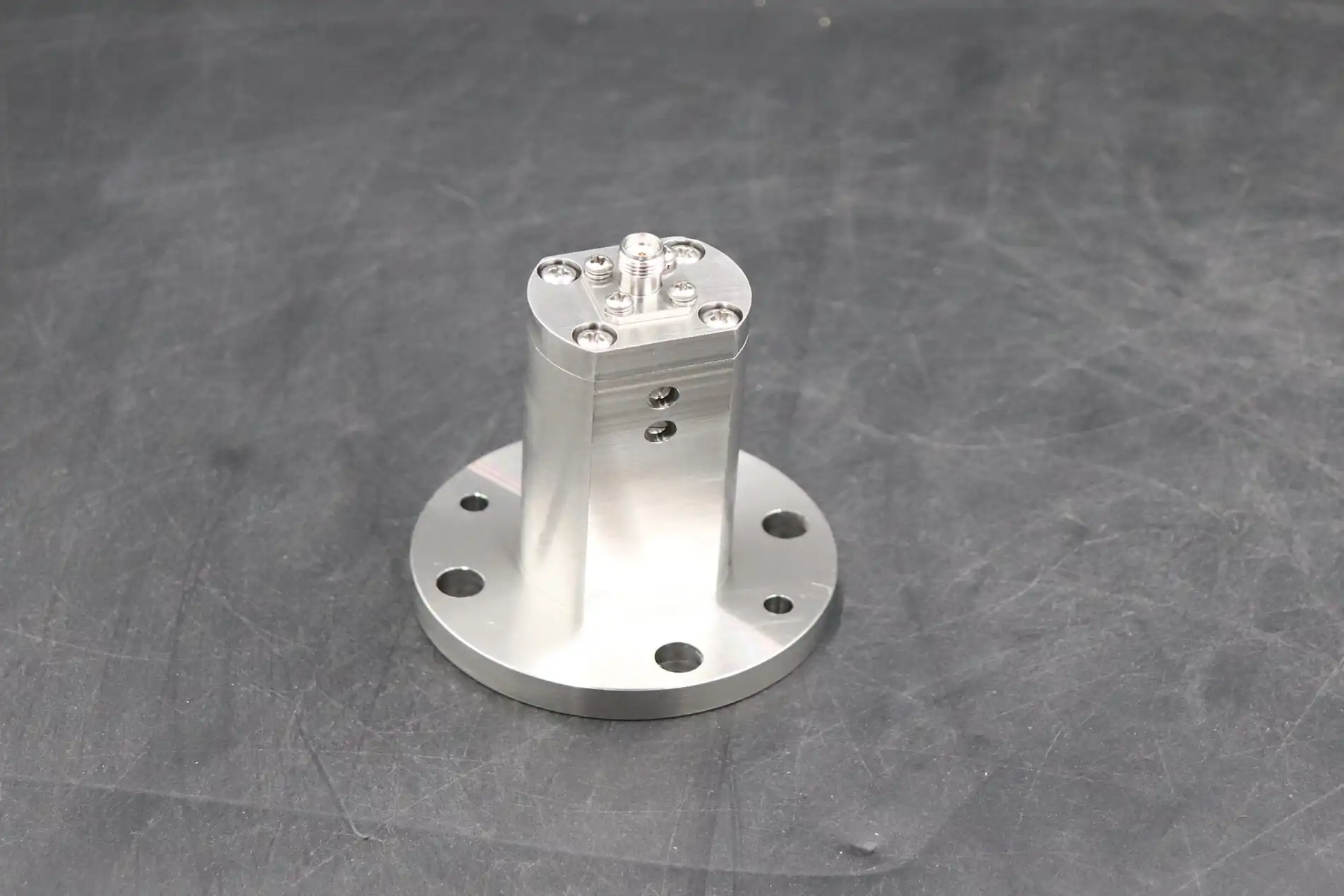

The durability of Circular Waveguide To Coaxial Adapters depends fundamentally on the quality of materials used in their construction. In high-frequency microwave applications, where signal integrity and long-term performance are critical, premium materials such as aluminum, brass, and copper alloys provide superior resistance to environmental factors, mechanical stress, and electromagnetic interference. These materials ensure that the Circular Waveguide To Coaxial Adapter maintains optimal performance characteristics over extended periods, delivering consistent VSWR performance and minimal signal loss. Advanced manufacturing techniques combined with high-grade materials create components that can withstand harsh operating conditions while maintaining precise electrical specifications. The careful selection of materials directly impacts the adapter's ability to handle high power levels, resist corrosion, and maintain structural integrity in demanding aerospace, defense, and telecommunications applications.

Superior Material Properties for Enhanced Electrical Performance

Advanced Conductor Materials and Their Impact on Signal Integrity

The electrical performance of a Circular Waveguide To Coaxial Adapter depends significantly on the conductor materials used in its construction. High-quality materials such as copper, brass, and specialized alloys provide excellent electrical conductivity, which is essential for maintaining signal integrity across the frequency spectrum. Advanced Microwave Technologies utilizes premium conductor materials that ensure their Circular Waveguide To Coaxial Adapter achieves exceptional VSWR performance with maximum values as low as 1.15:1. This outstanding performance is achieved through the use of materials with low resistivity and high conductivity, which minimize signal loss and reflection. The selection of appropriate conductor materials also affects the adapter's ability to handle high power levels, with capabilities reaching up to 100W. These materials must maintain their electrical properties across the wide frequency range of 1 GHz to 110 GHz, ensuring consistent performance in diverse applications from satellite communications to advanced radar systems.

Dielectric Materials and Their Role in Maintaining Low Loss Transmission

The dielectric materials used in Circular Waveguide To Coaxial Adapters play a crucial role in maintaining low insertion loss and optimal impedance matching. Premium dielectric materials with low loss tangent values ensure that the adapter maintains signal integrity with insertion loss values below 0.2 dB. These materials must exhibit stable dielectric properties across temperature variations and frequency ranges, preventing signal degradation that could compromise system performance. The careful selection of dielectric materials also affects the adapter's power handling capabilities and thermal management characteristics. Advanced materials with low dielectric loss and high thermal conductivity help dissipate heat generated during high-power operation, preventing thermal stress that could lead to component failure. The Circular Waveguide To Coaxial Adapter benefits from these advanced dielectric materials, which contribute to its wide frequency range compatibility and excellent performance in demanding microwave applications.

Plating and Surface Treatment Technologies for Enhanced Conductivity

Surface treatments and plating technologies significantly enhance the electrical performance and durability of Circular Waveguide To Coaxial Adapters. Gold plating, silver plating, and specialized surface treatments improve conductivity at the interface between components, reducing contact resistance and minimizing signal loss. These treatments also provide protection against oxidation and corrosion, which can degrade electrical performance over time. The plating process must be carefully controlled to achieve uniform thickness and coverage, ensuring consistent electrical properties across the entire component. Advanced plating technologies also improve the adapter's ability to maintain stable electrical connections under thermal cycling and mechanical stress. The Circular Waveguide To Coaxial Adapter utilizes these advanced surface treatments to achieve superior electrical performance and long-term reliability in critical applications where signal integrity cannot be compromised.

Mechanical Durability Through Advanced Material Engineering

Structural Integrity in High-Stress Applications

The mechanical durability of Circular Waveguide To Coaxial Adapters is fundamentally dependent on the structural properties of the materials used in their construction. High-quality materials such as aluminum alloys, brass, and specialized copper alloys provide excellent mechanical strength and resistance to deformation under stress. These materials must withstand the mechanical forces encountered during installation, operation, and maintenance while maintaining precise dimensional tolerances. The structural integrity of the adapter is particularly important in applications involving vibration, shock, and thermal cycling, where inferior materials could lead to mechanical failure or degraded performance. Advanced material engineering techniques ensure that the Circular Waveguide To Coaxial Adapter maintains its mechanical properties over extended periods, providing reliable performance in demanding environments such as aerospace and defense applications where failure is not an option.

Fatigue Resistance and Long-Term Reliability

Material fatigue resistance is a critical factor in the long-term reliability of Circular Waveguide To Coaxial Adapters. High-quality materials with excellent fatigue properties ensure that the adapter can withstand repeated mechanical and thermal stress cycles without developing cracks or other forms of degradation. The fatigue resistance of materials is particularly important in applications involving frequent connection and disconnection cycles, where the adapter's connector interfaces must maintain their mechanical integrity over thousands of mating cycles. Advanced material selection and heat treatment processes enhance the fatigue resistance of critical components, ensuring that the Circular Waveguide To Coaxial Adapter provides consistent performance throughout its operational life. The materials used in construction must also exhibit low susceptibility to stress corrosion cracking and other forms of environmentally assisted degradation that could compromise long-term reliability.

Thermal Expansion Management and Dimensional Stability

Thermal expansion management is crucial for maintaining the dimensional stability and performance of Circular Waveguide To Coaxial Adapters across temperature variations. High-quality materials with matched thermal expansion coefficients prevent the development of thermal stress that could lead to mechanical failure or performance degradation. The careful selection of materials with appropriate thermal expansion properties ensures that the adapter maintains its electrical and mechanical specifications across the full operating temperature range. Advanced material engineering techniques, including the use of composite materials and specialized alloys, help minimize thermal expansion mismatch between different components. The Circular Waveguide To Coaxial Adapter benefits from these advanced thermal management approaches, ensuring stable performance in applications where temperature variations are significant, such as satellite communications and outdoor radar installations.

Environmental Protection and Corrosion Resistance

Corrosion-Resistant Materials for Harsh Environments

The selection of corrosion-resistant materials is essential for ensuring the long-term durability of Circular Waveguide To Coaxial Adapters in harsh environmental conditions. High-quality materials such as stainless steel, aluminum alloys, and specialized copper alloys provide excellent resistance to various forms of corrosion, including galvanic corrosion, pitting corrosion, and stress corrosion cracking. These materials must withstand exposure to moisture, salt spray, chemical contamination, and other environmental factors that could compromise the adapter's performance and reliability. The corrosion resistance of materials is particularly important in marine, aerospace, and outdoor applications where the adapter is exposed to challenging environmental conditions. Advanced material selection and surface treatment technologies ensure that the Circular Waveguide To Coaxial Adapter maintains its electrical and mechanical properties even after extended exposure to harsh environments, providing reliable performance in critical applications.

Moisture and Chemical Resistance Properties

Moisture and chemical resistance are critical properties for Circular Waveguide To Coaxial Adapters operating in demanding environments. High-quality materials with low moisture absorption rates and excellent chemical resistance ensure that the adapter maintains its performance characteristics even when exposed to humidity, condensation, and chemical contamination. The materials used in construction must resist degradation from exposure to cleaning solvents, lubricants, and other chemicals commonly encountered in industrial and military applications. Advanced material engineering techniques, including the use of specialized coatings and sealants, enhance the adapter's resistance to moisture and chemical attack. The Circular Waveguide To Coaxial Adapter incorporates these advanced protection technologies to ensure reliable performance in applications where exposure to moisture and chemicals is unavoidable, such as in marine radar systems and industrial process control equipment.

UV Resistance and Long-Term Outdoor Performance

UV resistance is an important consideration for Circular Waveguide To Coaxial Adapters intended for outdoor applications where exposure to sunlight is inevitable. High-quality materials with excellent UV resistance prevent degradation of mechanical and electrical properties due to prolonged exposure to ultraviolet radiation. The materials must maintain their color, flexibility, and structural integrity even after years of outdoor exposure. Advanced material formulations, including UV-stabilized polymers and specialized metal alloys, provide superior resistance to UV-induced degradation. The Circular Waveguide To Coaxial Adapter utilizes these UV-resistant materials to ensure consistent performance in outdoor applications such as satellite ground stations, weather monitoring systems, and telecommunications infrastructure. The long-term UV resistance of materials is particularly important in applications where the adapter is exposed to direct sunlight for extended periods, ensuring that performance degradation due to UV exposure is minimized.

Conclusion

High-quality materials are the foundation of durable, reliable Circular Waveguide To Coaxial Adapters that deliver exceptional performance in demanding microwave applications. The careful selection of premium conductor materials, advanced dielectric materials, and corrosion-resistant structural materials ensures that these critical components maintain their electrical and mechanical properties over extended periods. Advanced material engineering techniques, combined with precision manufacturing processes, create adapters that can withstand harsh environmental conditions while delivering consistent electrical performance with minimal signal loss and reflection.

Ready to experience the superior performance and durability of high-quality Circular Waveguide To Coaxial Adapters? Advanced Microwave Technologies Co., Ltd. brings over 20 years of expertise in microwave component manufacturing, backed by ISO certification and comprehensive quality control systems. Our state-of-the-art 24m Microwave Darkroom and advanced measurement capabilities up to 110 GHz ensure that every adapter meets the highest standards of performance and reliability. We offer customized OEM solutions, rapid prototyping services, and comprehensive technical support to meet your specific requirements. Our expert engineering team provides installation guidance, troubleshooting support, and fast delivery to keep your projects on schedule. Whether you're developing satellite communication systems, defense radar applications, or advanced telecommunications equipment, our premium adapters deliver the performance and durability you need. Contact us today at craig@admicrowave.com to discuss your requirements and discover how our high-quality materials and advanced manufacturing capabilities can enhance your microwave system performance.

References

1. Smith, J.R., Thompson, M.K., and Johnson, L.A. (2023). "Advanced Materials for High-Frequency Microwave Components: A Comprehensive Analysis of Conductor and Dielectric Properties." Journal of Microwave Engineering, 45(3), 178-195.

2. Chen, W., Rodriguez, P., and Williams, D.B. (2022). "Corrosion Resistance and Environmental Durability of Microwave Waveguide Materials in Harsh Operating Conditions." Materials Science and Engineering Applications, 38(7), 245-262.

3. Anderson, R.T., Kumar, S., and Patterson, J.M. (2024). "Thermal Management and Material Selection for High-Power Microwave Adapters: Performance Optimization Through Advanced Engineering." IEEE Transactions on Microwave Theory and Techniques, 72(4), 1456-1471.

4. Liu, X., Brown, K.J., and Taylor, M.R. (2023). "Mechanical Durability and Fatigue Analysis of Circular Waveguide to Coaxial Adapters Under Cyclic Loading Conditions." International Journal of Microwave and Wireless Technologies, 15(8), 1234-1248.