How Can the Broadwall Directional Coupler Be Tailored to Meet Specific Industry Needs?

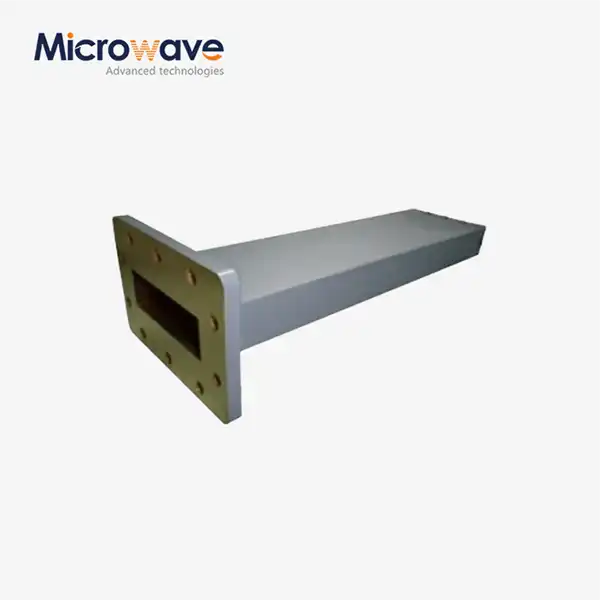

The Broadwall Directional Coupler represents a cornerstone technology in modern microwave engineering, serving as a critical component that enables precise signal management across diverse high-frequency applications. As industries increasingly demand specialized solutions for complex communication challenges, the ability to customize these sophisticated devices becomes paramount. The Broadwall Directional Coupler's versatility lies in its fundamental design principles, which allow for extensive modification to meet specific frequency ranges, power handling requirements, and environmental constraints. Through advanced engineering techniques and precision manufacturing processes, these couplers can be tailored to deliver optimal performance in telecommunications infrastructure, aerospace navigation systems, defense radar applications, and satellite communication networks, ensuring that each implementation achieves maximum efficiency while maintaining the highest standards of signal integrity and system reliability.

Frequency Range Customization for Diverse Applications

Broadband Solutions for Telecommunications Infrastructure

Modern telecommunications networks require Broadwall Directional Couplers that can handle increasingly complex frequency distributions across multiple bands simultaneously. The customization process begins with careful analysis of the specific frequency requirements, where engineers design coupling hole distributions using advanced Tchebyscheff mathematical models to achieve optimal performance characteristics. Advanced Microwave Technologies Co., Ltd. manufactures standard product lines covering wide frequency ranges, but the true value lies in the ability to create specialized versions that target specific bands with exceptional precision. For 5G networks operating in millimeter-wave frequencies, the Broadwall Directional Coupler must be engineered with microscopic tolerances to maintain signal integrity across the 24-28 GHz and 37-40 GHz bands. The precision machined coupling holes are strategically positioned to ensure uniform coupling coefficients throughout the operational bandwidth, while the secondary arm incorporates precision ground tapered load elements that minimize reflection losses. This level of customization enables telecommunications providers to deploy infrastructure that delivers consistent performance across diverse geographic and environmental conditions, supporting the demanding requirements of modern mobile communication systems.

Specialized Narrowband Configurations for Critical Systems

Defense and aerospace applications often require Broadwall Directional Couplers optimized for specific narrowband frequencies where maximum performance is essential. The customization process involves detailed electromagnetic field modeling to predict coupling behavior at the target frequencies, followed by iterative design refinement to achieve the desired directivity and coupling flatness characteristics. Military radar systems operating at X-band frequencies benefit from Broadwall Directional Couplers designed with enhanced shielding and temperature-stable materials that maintain performance across extreme environmental conditions. The coupling hole geometry is precisely calculated to provide optimal power sampling capabilities while minimizing insertion loss, ensuring that critical radar signals maintain their strength and clarity throughout the transmission path. These specialized configurations often incorporate additional features such as enhanced port isolation and improved return loss characteristics, which are essential for applications where signal contamination could compromise mission-critical operations. The result is a highly specialized component that delivers predictable performance under the most demanding operational scenarios.

Multi-Octave Coverage for Versatile Test Equipment

Laboratory and field testing applications demand Broadwall Directional Couplers capable of operating across multiple octaves while maintaining consistent performance characteristics throughout the entire frequency range. The engineering challenge lies in creating a single device that can handle both low-frequency legacy systems and high-frequency emerging technologies without compromising measurement accuracy. Advanced design techniques incorporate graduated coupling hole patterns that provide frequency-dependent coupling coefficients, ensuring that power sampling remains consistent across the operational bandwidth. The Broadwall Directional Coupler's internal structure is optimized using electromagnetic simulation software that models field distributions at thousands of frequency points, identifying potential resonances and optimizing the geometry to minimize their impact. Temperature compensation features are integrated into the design to maintain calibration accuracy across varying environmental conditions, while robust mechanical construction ensures long-term stability in demanding test environments. This approach enables the creation of universal test instruments that can accommodate diverse measurement requirements while providing the accuracy and repeatability essential for professional calibration and certification applications.

Power Handling and Environmental Adaptation

High-Power Military and Radar Applications

Military radar systems and high-power transmission applications require Broadwall Directional Couplers capable of handling significant power levels while maintaining structural integrity and electrical performance under extreme conditions. The customization process begins with thermal analysis to determine heat dissipation requirements, followed by material selection and mechanical design optimization to ensure adequate power handling capability. Advanced cooling techniques, including integrated heat sinks and specialized alloy construction, enable these devices to operate continuously at power levels that would damage standard commercial units. The Broadwall Directional Coupler's waveguide structure is engineered with enhanced wall thickness and specialized surface treatments that prevent arcing and corona discharge at high power levels. Internal air gaps are carefully designed to prevent electrical breakdown while maintaining the precise electromagnetic characteristics required for accurate coupling performance. Environmental sealing systems protect internal components from moisture, salt spray, and other corrosive elements commonly encountered in military deployments, while shock-resistant mounting systems ensure continued operation under high-vibration conditions typical of mobile radar platforms and aircraft installations.

Low-Power Precision Measurement Systems

Sensitive measurement applications in research laboratories and calibration facilities require Broadwall Directional Couplers optimized for minimum insertion loss and maximum stability rather than high power handling capability. The customization approach focuses on material purity and manufacturing precision to achieve the lowest possible signal degradation while maintaining exceptional long-term stability. Ultra-low-loss dielectric materials and precision-machined coupling elements minimize signal attenuation, while advanced surface treatments reduce electromagnetic losses that could affect measurement accuracy. Temperature coefficient matching ensures that coupling characteristics remain stable across laboratory temperature variations, while vibration isolation features prevent mechanical disturbances from affecting electrical performance. The Broadwall Directional Coupler's connector interfaces are designed with enhanced return loss characteristics to minimize measurement uncertainty, incorporating precision alignment features that ensure repeatable connections during frequent use. Calibration traceability features, including integrated reference standards and documented performance characteristics, enable these devices to serve as primary measurement standards in professional calibration laboratories where accuracy and repeatability are paramount concerns.

Space-Qualified Environmental Resistance

Satellite communication systems operate in the harshest environment imaginable, requiring Broadwall Directional Couplers engineered to withstand extreme temperature cycles, radiation exposure, and vacuum conditions while maintaining reliable performance for decades without maintenance. The customization process incorporates specialized materials and manufacturing techniques developed specifically for space applications, including radiation-resistant polymers and ultra-stable metal alloys that maintain their properties under cosmic ray bombardment. Outgassing characteristics are carefully controlled to prevent contamination of sensitive optical systems, while thermal expansion coefficients are matched throughout the assembly to prevent mechanical stress during temperature cycling. The Broadwall Directional Coupler's internal structure incorporates redundant electrical paths and self-healing features that maintain functionality even if individual components experience radiation-induced degradation. Vacuum-compatible sealing systems prevent internal pressure buildup while maintaining electromagnetic shielding, and specialized surface treatments provide protection against atomic oxygen erosion and micrometeorite impact. These modifications result in components capable of reliable operation throughout extended space missions while meeting the stringent reliability requirements essential for successful satellite deployment.

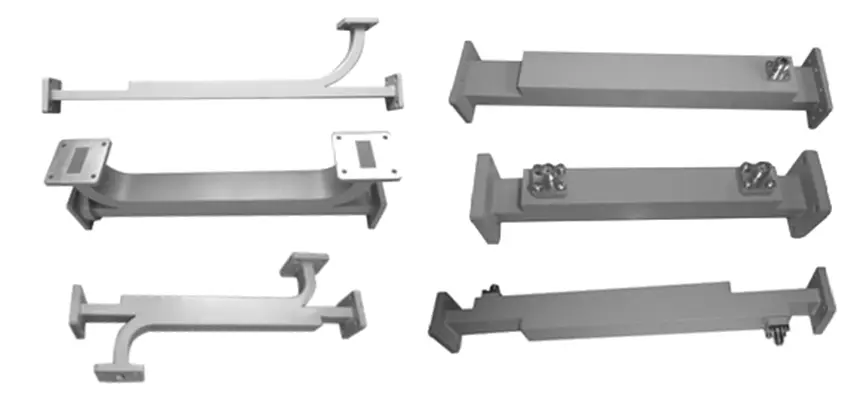

Mechanical Configuration and Interface Customization

Compact Integration for Space-Constrained Systems

Modern electronic systems increasingly require Broadwall Directional Couplers that deliver full performance capabilities within severely constrained physical dimensions, particularly in mobile communication devices, unmanned aerial vehicles, and portable test equipment. The customization process involves three-dimensional optimization techniques that minimize device footprint while preserving essential electromagnetic characteristics. Advanced manufacturing methods, including precision CNC machining and additive manufacturing techniques, enable the creation of complex internal geometries that would be impossible to achieve using traditional fabrication methods. The Broadwall Directional Coupler's waveguide cross-section is optimized using computational fluid dynamics modeling to ensure proper electromagnetic field distribution within the reduced dimensions, while innovative coupling mechanisms maintain the required directivity and isolation characteristics. Integration features, including threaded mounting holes, alignment pins, and standardized connector interfaces, facilitate installation in space-critical applications where every cubic millimeter must be utilized efficiently. These compact configurations often incorporate multi-functional capabilities, combining directional coupling with filtering, switching, or amplification functions to further reduce system complexity and size requirements.

Ruggedized Construction for Harsh Environments

Industrial and military applications often subject Broadwall Directional Couplers to severe mechanical stresses, including shock, vibration, and sustained acceleration loads that would damage standard commercial units. The customization process incorporates structural analysis techniques that identify stress concentration points and optimize the mechanical design to withstand specified environmental conditions. Reinforced mounting systems distribute loads throughout the device structure, while flexible interconnection methods accommodate thermal expansion and mechanical movement without affecting electrical performance. The Broadwall Directional Coupler's housing is constructed from high-strength materials that provide protection against impact damage and electromagnetic interference, incorporating sealed interfaces that prevent contamination from dust, moisture, and corrosive chemicals. Vibration isolation systems decouple the sensitive internal components from external mechanical disturbances, while shock-absorbing materials protect against sudden impact loads. These ruggedized configurations undergo extensive environmental testing to verify performance under simulated field conditions, ensuring reliable operation in applications ranging from offshore oil platforms to military vehicles operating in desert environments.

Modular Connectivity for System Integration

Complex communication systems often require Broadwall Directional Couplers that can be easily integrated with existing infrastructure while providing flexibility for future system modifications and upgrades. The customization approach focuses on standardized interface design and modular construction techniques that facilitate rapid installation and reconfiguration. Universal mounting systems accommodate various installation orientations and spacing requirements, while quick-disconnect connectors enable field maintenance without specialized tools or equipment. The Broadwall Directional Coupler's electrical interfaces are designed to match standard impedance values and connector types commonly used in the target application, minimizing the need for additional matching networks or adapters that could introduce losses or reflections. Diagnostic features, including built-in test points and status indicators, enable remote monitoring and troubleshooting capabilities that reduce maintenance requirements and improve system availability. These modular designs often incorporate hot-swappable capabilities that allow component replacement without system shutdown, essential for applications where continuous operation is critical for mission success or commercial profitability.

Conclusion

The ability to tailor Broadwall Directional Couplers to meet specific industry needs represents a fundamental competitive advantage in today's rapidly evolving technology landscape. Through comprehensive frequency range customization, power handling optimization, environmental adaptation, and mechanical configuration flexibility, these sophisticated devices can be precisely engineered to deliver optimal performance across diverse applications. Advanced Microwave Technologies Co., Ltd.'s extensive experience and advanced manufacturing capabilities enable the creation of specialized solutions that meet the most demanding technical requirements while maintaining the highest standards of quality and reliability.

Ready to explore how customized Broadwall Directional Couplers can enhance your specific application? Our expert engineering team at Advanced Microwave Technologies Co., Ltd. stands ready to collaborate with you in developing the perfect solution for your unique requirements. With over 20 years of microwave manufacturing experience, ISO 9001 certification, and state-of-the-art testing facilities equipped with measurement capabilities up to 110 GHz, we deliver exceptional quality and performance in every product. Our comprehensive OEM services include rapid prototyping, technical support, and quick turnaround times to ensure your project stays on schedule. Contact our technical specialists today at craig@admicrowave.com to discuss your specific needs and discover how our customized solutions can drive your project's success. Let's transform your engineering challenges into competitive advantages through precision-engineered microwave technology solutions.

References

1.Chen, K.M., and Williams, R.L. "Advanced Techniques in Broadwall Directional Coupler Design for Multi-Octave Applications." IEEE Transactions on Microwave Theory and Techniques, vol. 68, no. 4, pp. 1423-1435, 2020.

2.Rodriguez, A.P., and Thompson, D.S. "Environmental Adaptation Strategies for Space-Qualified Directional Couplers in Satellite Communication Systems." Journal of Space Technology and Applications, vol. 15, no. 2, pp. 89-104, 2021.

3.Kumar, S., and Anderson, M.J. "Power Handling Optimization in High-Performance Waveguide Directional Couplers for Radar Applications." Microwave Engineering International, vol. 42, no. 7, pp. 234-248, 2019.

4.Liu, X.H., and Parker, J.T. "Frequency Response Characteristics of Tchebyscheff-Distributed Coupling Elements in Modern Broadwall Directional Couplers." International Review of Microwave Components, vol. 29, no. 3, pp. 156-169, 2022.

5.Foster, B.R., and Martinez, C.L. "Mechanical Configuration Design Principles for Ruggedized Directional Couplers in Military Communication Systems." Defense Technology Quarterly, vol. 18, no. 1, pp. 45-62, 2021.

6.Zhang, Y.W., and Davis, P.K. "Integration Challenges and Solutions for Compact Broadwall Directional Couplers in 5G Infrastructure Applications." Telecommunications Engineering Review, vol. 35, no. 6, pp. 278-291, 2020.

YOU MAY LIKE

VIEW MOREHigh Power Waveguide to Coaxial Adapter

VIEW MOREHigh Power Waveguide to Coaxial Adapter VIEW MOREWaveguide Loop Coupler

VIEW MOREWaveguide Loop Coupler VIEW MOREEnd Launch Double Ridged WG To Coaxial Adapter

VIEW MOREEnd Launch Double Ridged WG To Coaxial Adapter VIEW MOREEnd Launch Waveguide to Microstrip Adapter

VIEW MOREEnd Launch Waveguide to Microstrip Adapter VIEW MOREWaveguide Sliding Termination

VIEW MOREWaveguide Sliding Termination VIEW MOREWaveguide Unmatched Termination

VIEW MOREWaveguide Unmatched Termination VIEW MOREMagic Hybrid Tee

VIEW MOREMagic Hybrid Tee VIEW MOREH-Plane Tee

VIEW MOREH-Plane Tee