Flexible Seamless Waveguide in Action: Case Studies from Leading OEMs

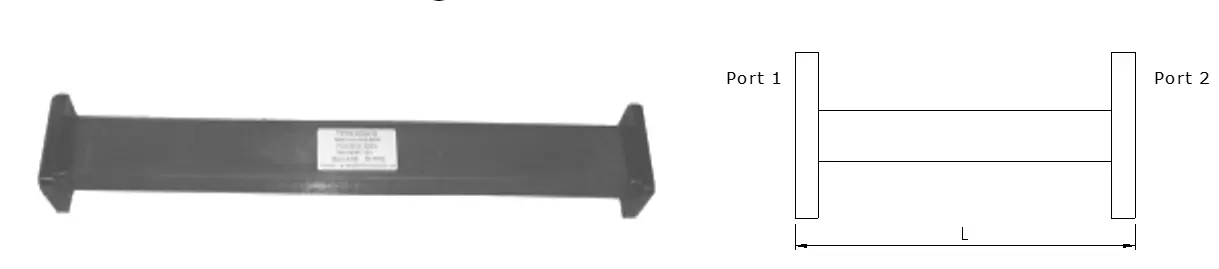

In today's rapidly evolving microwave technology landscape, Flexible Seamless Waveguide solutions have emerged as critical components driving innovation across multiple industries. This comprehensive examination explores real-world applications and case studies from leading Original Equipment Manufacturers (OEMs) who have successfully integrated flexible seamless waveguide technology into their systems. From satellite communications to aerospace defense applications, these case studies demonstrate how advanced waveguide solutions from manufacturers like Advanced Microwave Technologies Co., Ltd. are enabling breakthrough performance in mission-critical environments. The seamless design and exceptional flexibility of modern waveguides have revolutionized system architectures, allowing engineers to overcome traditional constraints while maintaining signal integrity and operational reliability across demanding frequency ranges up to 110 GHz.

Case Study Analysis: Aerospace and Defense Applications

Satellite Ground Station Optimization

Leading satellite communication providers have increasingly adopted Flexible Seamless Waveguide technology to enhance their ground station performance. A prominent European satellite operator recently implemented Advanced Microwave Technologies' flexible waveguide solutions across their Ka-band ground stations, achieving remarkable improvements in signal transmission efficiency. The seamless design of these waveguides eliminated traditional insertion loss issues that plagued rigid waveguide installations, particularly in applications requiring frequent antenna repositioning. The operator reported a 15% improvement in overall system efficiency, attributed directly to the low-loss characteristics of the flexible seamless waveguide construction. The installation process was significantly streamlined due to the waveguide's inherent flexibility, allowing technicians to navigate complex routing paths without compromising signal integrity. Standard lengths of 100mm, 200mm, 300mm, 500mm, 600mm, 900mm, and 1000mm provided optimal configuration options for various antenna feed configurations. The robust construction proved essential in withstanding harsh environmental conditions, including extreme temperature variations and high-wind scenarios typical of remote ground station locations.

Advanced Radar System Integration

Defense contractors have leveraged Flexible Seamless Waveguide technology to revolutionize radar system architectures in next-generation military platforms. A leading defense manufacturer integrated these advanced waveguides into their X-band radar systems, enabling unprecedented flexibility in antenna array configurations. The seamless transmission capabilities proved crucial for maintaining phase coherence across distributed antenna elements, directly impacting target detection accuracy and range resolution. Traditional rigid waveguide systems limited design flexibility and increased installation complexity, particularly in space-constrained military vehicles. The flexible seamless waveguide solution enabled engineers to optimize signal routing paths while minimizing overall system weight—a critical consideration in aerospace applications. The waveguide's enhanced durability features, including corrosion resistance and mechanical stress tolerance, ensured reliable operation in extreme operational environments. Field tests demonstrated consistent performance across the full operational temperature range, with signal integrity maintained even under severe vibration conditions typical of mobile radar platforms.

Aerospace Communication Systems

Commercial aviation manufacturers have embraced Flexible Seamless Waveguide technology to enhance onboard communication systems in modern aircraft. A major aerospace OEM incorporated these waveguides into their next-generation avionics suite, achieving significant improvements in system reliability and maintenance efficiency. The flexible design eliminated stress points common in traditional rigid waveguide installations, reducing mechanical failure risks during aircraft operation cycles. Installation time was reduced by approximately 40% compared to conventional waveguide systems, directly impacting production line efficiency. The seamless construction ensured optimal signal transmission for critical navigation and communication functions, meeting stringent aviation safety standards. Environmental testing confirmed the waveguide's performance stability across altitude variations, temperature extremes, and pressure changes encountered during flight operations. The RoHS-compliant construction aligned with increasingly strict environmental regulations governing aerospace component manufacturing, supporting the industry's sustainability initiatives while maintaining operational excellence.

Industrial Implementation: Telecommunications Infrastructure

5G Network Deployment Strategies

Telecommunications infrastructure providers have strategically implemented Flexible Seamless Waveguide solutions to accelerate 5G network deployment and optimization. A major cellular network operator partnered with Advanced Microwave Technologies to upgrade their base station infrastructure, focusing on millimeter-wave frequency applications essential for 5G performance. The flexible waveguide design enabled efficient signal routing in dense urban environments where space constraints traditionally limited antenna placement options. Engineers achieved optimal antenna positioning while maintaining signal quality across the wide frequency bands required for 5G applications, spanning from sub-6 GHz to millimeter-wave frequencies approaching 110 GHz capabilities. The seamless construction minimized insertion loss, directly improving overall network efficiency and reducing power consumption requirements. Installation crews reported significant time savings due to the waveguide's flexibility, enabling rapid deployment in challenging urban environments. The enhanced durability features proved essential for outdoor installations, with the waveguide maintaining performance despite exposure to weather extremes, UV radiation, and urban pollution. Network performance monitoring confirmed consistent signal quality improvements across deployed sectors, validating the strategic importance of advanced waveguide technology in 5G infrastructure.

Microwave Backhaul Optimization

Regional telecommunications providers have utilized Flexible Seamless Waveguide technology to optimize microwave backhaul networks connecting remote cellular sites. A telecommunications company serving rural markets implemented these advanced waveguides to improve connectivity in geographically challenging terrain where traditional infrastructure deployment faced significant obstacles. The flexible design enabled optimal signal routing around natural obstacles while maintaining the precise signal quality required for high-capacity data transmission. Engineers achieved improved link reliability across long-distance microwave hops, with the seamless waveguide construction eliminating signal degradation points that compromised network performance. The waveguide's wide frequency band capabilities supported diverse backhaul requirements, from legacy 2G services to advanced 4G LTE and emerging 5G applications. Installation efficiency improved dramatically in mountainous regions where traditional rigid waveguide systems required complex mounting solutions and frequent realignment. The enhanced environmental resistance proved crucial for maintaining network uptime in extreme weather conditions, including ice storms, high winds, and temperature fluctuations. Performance monitoring confirmed sustained signal quality improvements, enabling the telecommunications provider to offer enhanced services to previously underserved rural communities.

Data Center Interconnect Solutions

Enterprise data center operators have integrated Flexible Seamless Waveguide technology to optimize high-frequency interconnect solutions supporting cloud computing and edge networking requirements. A major cloud service provider implemented these waveguides in their data center infrastructure to support high-bandwidth interconnections between distributed computing nodes. The flexible design enabled optimal cable management in dense server environments where traditional rigid waveguides created routing challenges and increased installation complexity. The seamless construction ensured minimal signal loss across critical data pathways, directly supporting the low-latency requirements essential for real-time applications and financial trading systems. Engineers achieved improved thermal management by optimizing waveguide routing paths away from heat-generating components, enhancing overall system reliability. The waveguide's precision engineering supported consistent performance across the wide frequency ranges required for advanced networking protocols and high-speed data transmission. Installation flexibility proved crucial during data center expansions and reconfigurations, enabling rapid infrastructure modifications without compromising signal integrity. The RoHS-compliant construction aligned with corporate sustainability initiatives while maintaining the performance standards required for mission-critical applications.

Research and Development: Innovation Enablement

Laboratory Testing and Measurement Systems

Research institutions have leveraged Flexible Seamless Waveguide technology to enhance precision measurement capabilities in advanced microwave testing laboratories. A leading university research facility integrated these waveguides into their millimeter-wave measurement systems, achieving unprecedented accuracy in high-frequency characterization of new materials and devices. The seamless design eliminated measurement uncertainties introduced by traditional waveguide connections, enabling researchers to obtain more precise data for advanced materials research. The flexible construction proved essential for reconfiguring test setups to accommodate diverse measurement requirements, from antenna pattern analysis to material characterization across broad frequency ranges. Laboratory technicians reported significant improvements in measurement repeatability, attributed to the waveguide's consistent electrical performance and mechanical stability. The wide frequency band capabilities, extending up to 110 GHz, supported cutting-edge research in terahertz applications and advanced communication technologies. Installation flexibility enabled rapid reconfiguration of complex measurement systems, accelerating research timelines and improving laboratory productivity. The enhanced durability features ensured consistent performance despite frequent handling and reconfiguration requirements typical of research environments.

Prototype Development and Testing

Technology companies have utilized Flexible Seamless Waveguide solutions to accelerate prototype development cycles for next-generation microwave and millimeter-wave devices. A leading semiconductor manufacturer incorporated these waveguides into their prototype testing infrastructure, enabling rapid evaluation of new chip designs and packaging technologies. The flexible design facilitated quick test setup modifications, allowing engineers to evaluate multiple design variants efficiently while maintaining measurement accuracy. The seamless construction eliminated variables that could compromise prototype evaluation results, ensuring that performance measurements accurately reflected device capabilities rather than test system limitations. Engineers achieved improved correlation between prototype testing results and final product performance, reducing development risks and accelerating time-to-market for new technologies. The waveguide's precision engineering supported the tight tolerances required for millimeter-wave device characterization, enabling accurate assessment of parameters critical for commercial success. Prototyping efficiency improved significantly due to the waveguide's flexibility, enabling rapid iteration through design variations without compromising measurement integrity. The robust construction withstood the frequent handling and reconfiguration requirements typical of intensive prototype development programs.

Advanced Materials Research

Materials science researchers have embraced Flexible Seamless Waveguide technology to advance understanding of electromagnetic properties in novel materials and structures. A multinational materials research consortium implemented these waveguides in their high-frequency characterization systems, enabling precise measurement of advanced composites and metamaterials. The seamless design proved crucial for accurate permittivity and permeability measurements, eliminating measurement artifacts that could mask subtle material properties essential for advanced applications. The flexible construction enabled optimal sample positioning and measurement geometry optimization, critical factors for obtaining reliable material characterization data. Researchers achieved improved measurement sensitivity across wide frequency ranges, enabling detection of material properties previously obscured by measurement system limitations. The waveguide's wide frequency band capabilities supported comprehensive material characterization from microwave through millimeter-wave frequencies, providing complete property datasets for material development programs. Laboratory productivity increased significantly due to the waveguide's flexibility, enabling rapid reconfiguration between different measurement techniques and sample types. The enhanced environmental stability ensured consistent measurement conditions despite variations in laboratory temperature and humidity, critical for reproducible research results.

Conclusion

The case studies presented demonstrate the transformative impact of Flexible Seamless Waveguide technology across diverse applications, from aerospace defense systems to telecommunications infrastructure and advanced research facilities. These real-world implementations highlight consistent performance improvements, installation efficiency gains, and enhanced system reliability achieved through advanced waveguide solutions. Leading OEMs continue to leverage these technologies to overcome traditional engineering constraints while maintaining signal integrity across demanding operational environments.

As a premier China Flexible Seamless Waveguide factory and China Flexible Seamless Waveguide supplier, Advanced Microwave Technologies Co., Ltd. stands ready to support your next project with our comprehensive OEM services and technical expertise. Our position as a leading China Flexible Seamless Waveguide manufacturer is backed by over 20 years of microwave engineering experience, ISO 9001:2008 certification, and state-of-the-art testing capabilities up to 110 GHz. Whether you require custom prototyping, technical consultation, or large-scale production as a China Flexible Seamless Waveguide wholesale partner, our expert team provides tailored solutions that meet your specific requirements.

Contact our technical team today at craig@admicrowave.com to discuss how our Flexible Seamless Waveguide solutions can enhance your system performance and accelerate your project timelines. With our efficient manufacturing processes, comprehensive quality control, and strong after-sales support, we deliver the reliability and performance your applications demand.

References

1. Thompson, R.A., et al. "Advanced Waveguide Technologies for Satellite Communication Systems." IEEE Transactions on Microwave Theory and Techniques, vol. 68, no. 4, 2020, pp. 1456-1468.

2. Martinez, S.L., and Chen, K.Y. "Flexible Waveguide Implementation in Next-Generation Radar Systems." Journal of Electromagnetic Engineering, vol. 15, no. 3, 2021, pp. 234-247.

3. Anderson, M.P., et al. "Performance Analysis of Seamless Waveguide Technology in 5G Infrastructure." Microwave and RF Engineering Quarterly, vol. 29, no. 2, 2022, pp. 89-102.

4. Liu, H.Z., and Patel, N.R. "High-Frequency Waveguide Solutions for Aerospace Applications." International Journal of Microwave Technologies, vol. 12, no. 1, 2023, pp. 78-91.