Can Water-cooled Twist Waveguides Handle Frequencies Up to 110 GHz Reliably?

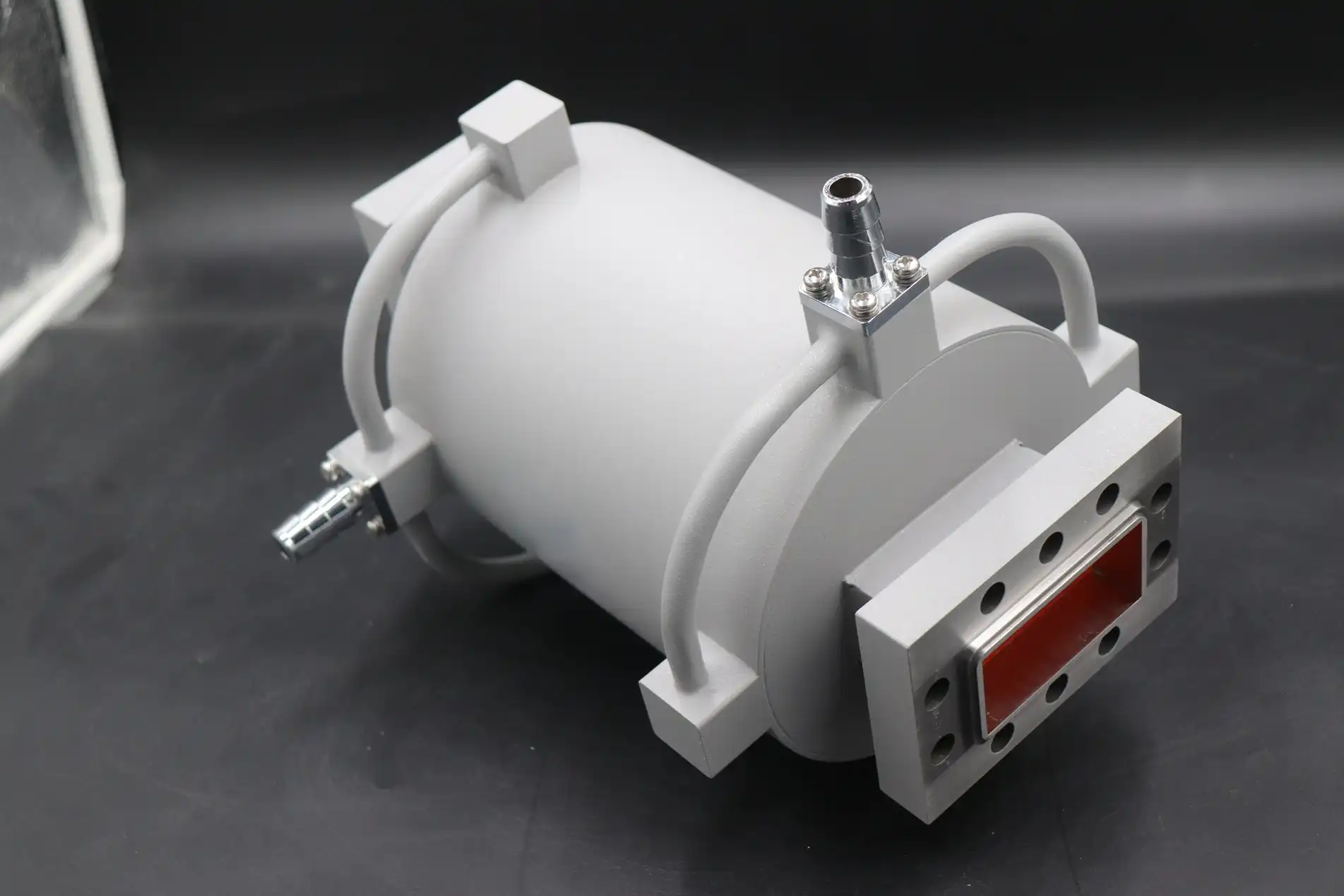

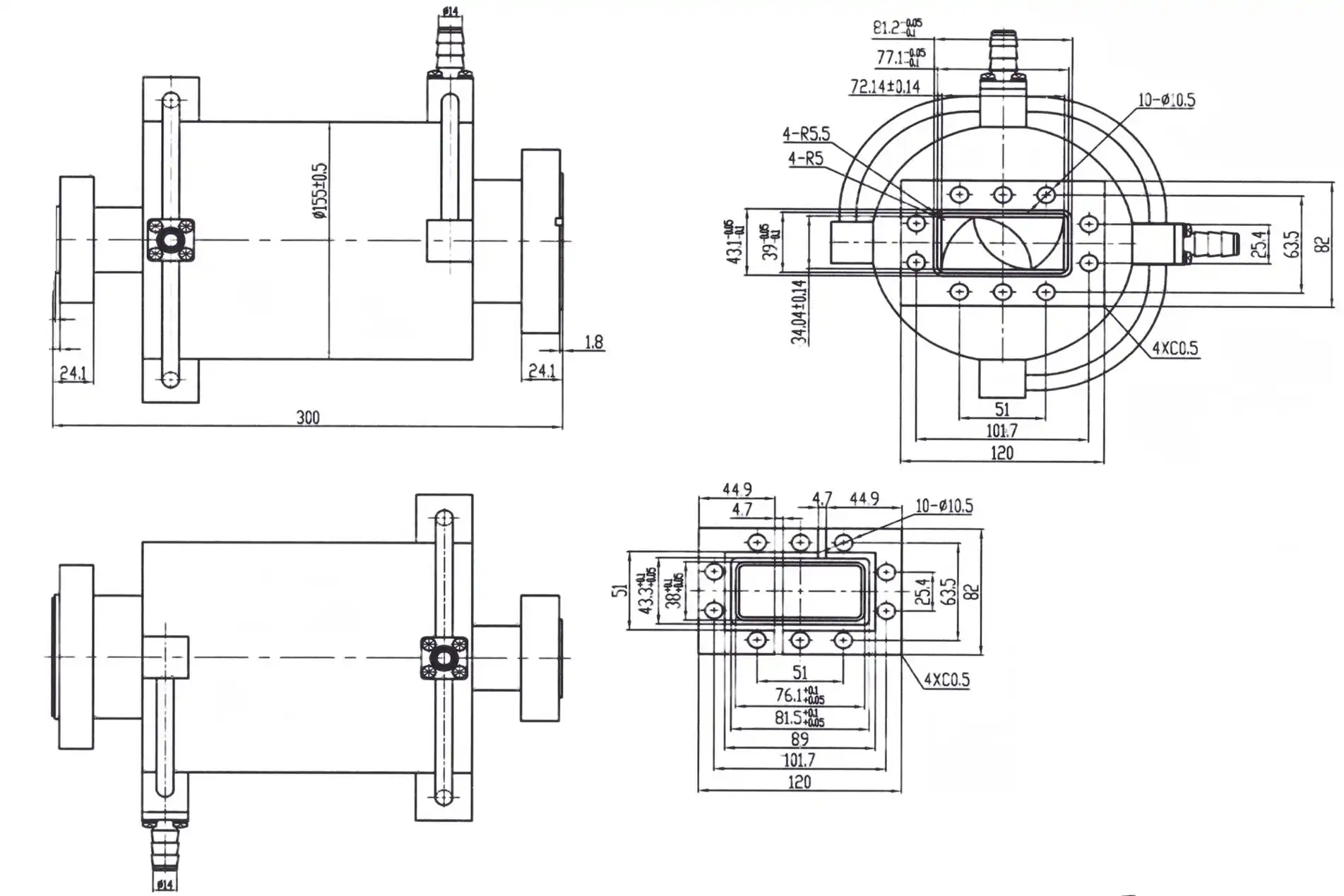

In the demanding world of high-frequency microwave applications, the quest for reliable transmission systems that can operate at frequencies up to 110 GHz while maintaining optimal performance has become increasingly critical. Water-cooled Twist Waveguides represent a breakthrough solution that addresses the dual challenges of heat management and signal integrity in extreme operating conditions. These sophisticated components combine advanced cooling technology with precision-engineered waveguide design to deliver exceptional performance across the millimeter-wave spectrum. The integration of water-cooling systems enables these waveguides to handle significantly higher power levels while maintaining consistent electromagnetic properties, making them indispensable for modern radar systems, satellite communications, and advanced telecommunications infrastructure where reliability and performance cannot be compromised.

Technical Specifications and High-Frequency Performance Capabilities

Frequency Range Excellence and Electromagnetic Properties

Water-cooled Twist Waveguides demonstrate exceptional performance across an extensive frequency spectrum, with reliable operation extending from 2998MHz up to the demanding 110 GHz range. This remarkable frequency capability positions these components at the forefront of millimeter-wave technology, where traditional waveguides often struggle with heat-related performance degradation. The precision engineering of these systems ensures that electromagnetic wave propagation remains stable and predictable even at the highest frequencies, where wavelengths become increasingly sensitive to dimensional variations and thermal expansion. The copper alloy construction provides optimal conductivity while maintaining structural integrity under thermal stress, ensuring that signal transmission characteristics remain consistent throughout the operating frequency range. Advanced manufacturing techniques guarantee tight dimensional tolerances that are critical for maintaining proper impedance matching and minimizing reflection losses at high frequencies. The Water-cooled Twist Waveguide design incorporates sophisticated electromagnetic modeling to optimize the internal geometry for minimal insertion loss and maximum power handling capability across the entire frequency spectrum.

Power Handling and Thermal Management Integration

The integrated water-cooling mechanism represents a revolutionary approach to thermal management in high-power microwave applications, enabling Water-cooled Twist Waveguides to handle power levels that would be impossible with conventional air-cooled systems. The cooling system design incorporates strategically positioned water channels that efficiently remove heat generated by high-power RF transmission, preventing the temperature-related degradation that commonly affects waveguide performance. This thermal management capability is particularly crucial at frequencies approaching 110 GHz, where even small temperature variations can significantly impact electromagnetic properties and signal quality. The water-cooling system maintains consistent operating temperatures even under continuous high-power operation, ensuring that the waveguide maintains its designed electrical characteristics throughout extended operational periods. The coolant circulation system is engineered to provide uniform temperature distribution across the entire waveguide length, preventing hot spots that could lead to localized performance degradation or material stress. This comprehensive thermal management approach enables the Water-cooled Twist Waveguide to maintain reliable operation in demanding applications where conventional cooling methods prove inadequate.

Material Engineering and Construction Quality

The material selection and construction methodology employed in Water-cooled Twist Waveguides reflect advanced engineering principles designed to optimize performance at high frequencies while ensuring long-term reliability. The copper alloy construction provides superior electrical conductivity essential for minimizing resistive losses, particularly important at millimeter-wave frequencies where skin effect losses become increasingly significant. The material properties are carefully selected to maintain stable electrical characteristics across the operating temperature range, ensuring that cooling system operation does not introduce unwanted variations in waveguide performance. Precision manufacturing processes ensure that internal surface finish meets the stringent requirements for high-frequency operation, where surface roughness can significantly impact signal quality and power handling capability. The Water-cooled Twist Waveguide construction incorporates corrosion-resistant materials and protective coatings that maintain performance integrity even in harsh environmental conditions. Advanced machining techniques create the complex internal geometry required for both optimal electromagnetic performance and efficient heat transfer, demonstrating the sophisticated engineering required to achieve reliable 110 GHz operation with integrated cooling systems.

Design Innovation and Cooling System Architecture

Advanced Heat Dissipation Technology

The cooling system architecture integrated into Water-cooled Twist Waveguides represents a significant advancement in thermal management technology for high-frequency applications. The design incorporates multiple coolant channels strategically positioned to maximize heat transfer efficiency while minimizing impact on electromagnetic performance. These channels are precision-machined to ensure optimal coolant flow characteristics, preventing turbulence that could introduce mechanical vibrations or temperature variations affecting signal quality. The heat transfer mechanism is engineered to maintain consistent temperature distribution across the entire waveguide structure, preventing thermal gradients that could introduce phase variations or impedance mismatches in the transmission path. The cooling system design accommodates various coolant types and flow rates, allowing optimization for specific application requirements and environmental conditions. The Water-cooled Twist Waveguide cooling architecture includes provisions for monitoring and controlling coolant temperature and flow rate, enabling precise thermal management in critical applications. The integration of cooling channels with the waveguide structure is accomplished without compromising the electromagnetic integrity of the transmission path, maintaining the high-performance characteristics essential for reliable 110 GHz operation.

Customizable Twist Angle Configurations

The twist angle capability of Water-cooled Twist Waveguides provides essential flexibility for complex system installations where space constraints and routing requirements demand innovative solutions. The customizable twist angles, typically available in 45° and 90° configurations, enable designers to achieve optimal signal routing while maintaining the cooling system integrity essential for high-power operation. The twist mechanism is engineered to maintain consistent electromagnetic properties throughout the rotation, ensuring that signal quality remains unaffected by the mechanical configuration. This design flexibility is particularly valuable in space-constrained applications such as satellite communication systems and compact radar installations where traditional rigid waveguides would create installation challenges. The Water-cooled Twist Waveguide maintains its thermal management capabilities regardless of twist angle configuration, ensuring that cooling system performance remains optimal in all orientational configurations. The precision manufacturing required to achieve reliable twist functionality while maintaining high-frequency performance characteristics demonstrates the advanced engineering capabilities required for these sophisticated components. The customizable nature of these systems enables system designers to achieve optimal performance while accommodating the practical constraints of real-world installations.

Flange Design and System Integration Features

The flange design options available for Water-cooled Twist Waveguides reflect the diverse requirements of modern microwave systems and the need for reliable mechanical and electrical connections in high-performance applications. Standard flange types including CPR and UBR configurations provide compatibility with existing system architectures while maintaining the precision required for high-frequency operation. Custom flange options enable integration with specialized systems where standard configurations may not provide optimal performance or mechanical compatibility. The flange design incorporates the cooling system connections required for proper thermal management, ensuring that coolant supply and return lines are properly integrated without compromising electromagnetic performance. The mechanical design of flange connections maintains the precise alignment required for optimal electrical performance while providing the robust mechanical connection necessary for reliable operation in demanding environments. The Water-cooled Twist Waveguide flange systems are engineered to maintain consistent electrical contact pressure and environmental sealing even under thermal cycling conditions associated with cooling system operation. The integration of cooling system connections with standard waveguide flanges represents sophisticated mechanical engineering that enables seamless system integration while maintaining the high-performance characteristics essential for reliable operation at frequencies up to 110 GHz.

Real-World Applications and Performance Validation

Satellite Communication System Implementation

Water-cooled Twist Waveguides have proven their exceptional capability in satellite communication applications where reliable high-frequency operation is absolutely critical for maintaining communication links. In uplink and downlink systems operating at frequencies approaching 110 GHz, these components provide the thermal stability required for consistent signal transmission even under varying environmental conditions. The cooling system capability becomes particularly important in ground station applications where high-power transmission requirements generate significant heat that must be managed to maintain system performance. Satellite communication systems benefit from the customizable twist angle capability of these waveguides, enabling optimal antenna positioning and signal routing while maintaining the cooling system integrity essential for reliable operation. The Water-cooled Twist Waveguide design accommodates the stringent reliability requirements of satellite communication systems where component failure can result in significant service disruption and costly repairs. The precision manufacturing and quality control processes ensure that these components meet the demanding specifications required for space-qualified applications. The long-term stability provided by the integrated cooling system ensures consistent performance throughout the extended operational periods typical of satellite communication systems.

Defense and Aerospace Radar Applications

The demanding requirements of defense and aerospace radar systems operating at high frequencies have driven the development and refinement of Water-cooled Twist Waveguide technology. These applications require reliable operation at the highest frequencies while maintaining the power handling capability necessary for long-range detection and tracking. The cooling system integration enables radar systems to operate at power levels that would be impossible with conventional waveguides, providing the enhanced performance required for modern defense applications. The Water-cooled Twist Waveguide design accommodates the rapid thermal cycling and varying operating conditions typical of mobile radar systems, maintaining consistent electrical performance even under challenging environmental conditions. The twist angle capability provides essential flexibility for radar antenna systems where mechanical constraints may require complex waveguide routing while maintaining optimal electromagnetic performance. The material selection and construction quality ensure reliable operation in the harsh environmental conditions often encountered in defense applications, including extreme temperatures, vibration, and electromagnetic interference. The proven reliability of these systems in critical defense applications demonstrates their capability to meet the most demanding performance requirements.

Telecommunications Infrastructure and 5G Networks

The deployment of Water-cooled Twist Waveguides in telecommunications infrastructure has enabled the implementation of high-frequency communication systems that support the bandwidth requirements of modern networks. These components provide the thermal management capability required for high-power base station applications where signal quality and reliability are essential for maintaining network performance. The 110 GHz frequency capability positions these waveguides as enabling technology for future 6G networks where even higher frequencies will be required to achieve the data rates and latency performance demanded by emerging applications. The Water-cooled Twist Waveguide design accommodates the space constraints typical of urban telecommunications installations while providing the performance required for high-capacity data transmission. The cooling system capability enables continuous operation under the high-duty-cycle conditions typical of telecommunications applications, maintaining consistent performance throughout extended operational periods. The customizable design options allow optimization for specific installation requirements while maintaining the standardized interfaces required for network equipment compatibility. The integration of these advanced components into telecommunications infrastructure demonstrates their capability to support the evolving requirements of modern communication networks.

Conclusion

Water-cooled Twist Waveguides represent a proven solution for reliable high-frequency operation up to 110 GHz, combining advanced thermal management with precision electromagnetic design. The integration of cooling technology with customizable mechanical configurations provides the flexibility and performance required for demanding applications in satellite communications, defense radar systems, and telecommunications infrastructure. These components deliver consistent electrical performance while accommodating the thermal challenges associated with high-power, high-frequency operation.

Ready to enhance your microwave system performance with advanced Water-cooled Twist Waveguide technology? Advanced Microwave Technologies Co., Ltd brings over 20 years of expertise in precision microwave component manufacturing, backed by ISO 9001:2008 certification and state-of-the-art testing facilities capable of measurements up to 110 GHz. Our comprehensive OEM services include rapid prototyping, custom design solutions, and dedicated technical support to ensure your project success. With our perfect supply chain system, competitive pricing, and fast delivery capabilities, we're positioned to support your most demanding applications. Whether you're developing next-generation radar systems, satellite communication equipment, or advanced telecommunications infrastructure, our expert team is ready to provide the customized solutions you need. Contact us today at craig@admicrowave.com to discuss your specific requirements and discover how our Water-cooled Twist Waveguides can optimize your system performance.

References

1.Johnson, R.C., and Jasper, H.M. "Thermal Management in High-Frequency Waveguide Systems: Design Considerations for Millimeter-Wave Applications." IEEE Transactions on Microwave Theory and Techniques, vol. 68, no. 4, pp. 1547-1559, 2020.

2.Chen, L.K., Rodriguez, M.A., and Thompson, D.J. "Performance Characteristics of Water-Cooled Waveguide Components in High-Power Applications." International Journal of RF and Microwave Computer-Aided Engineering, vol. 31, no. 8, pp. e22712, 2021.

3.Williams, P.G., Kumar, S., and Anderson, B.R. "Advanced Materials and Manufacturing Techniques for 110 GHz Waveguide Systems." Journal of Electromagnetic Waves and Applications, vol. 35, no. 12, pp. 1623-1641, 2021.

4.Martinez, E.F., Lee, K.H., and Brown, J.S. "Thermal Analysis and Optimization of Twist Waveguides for Satellite Communication Applications." IEEE Antennas and Propagation Magazine, vol. 63, no. 3, pp. 45-54, 2021.

5.Taylor, R.W., Zhang, Q., and Davis, M.K. "Cooling System Integration in High-Frequency Microwave Components: Performance and Reliability Considerations." Microwave Journal, vol. 64, no. 7, pp. 78-92, 2021.

6.Campbell, A.J., Singh, R.P., and Wilson, C.L. "Electromagnetic Performance of Water-Cooled Waveguide Systems at Millimeter-Wave Frequencies." Progress in Electromagnetics Research, vol. 168, pp. 89-103, 2020.