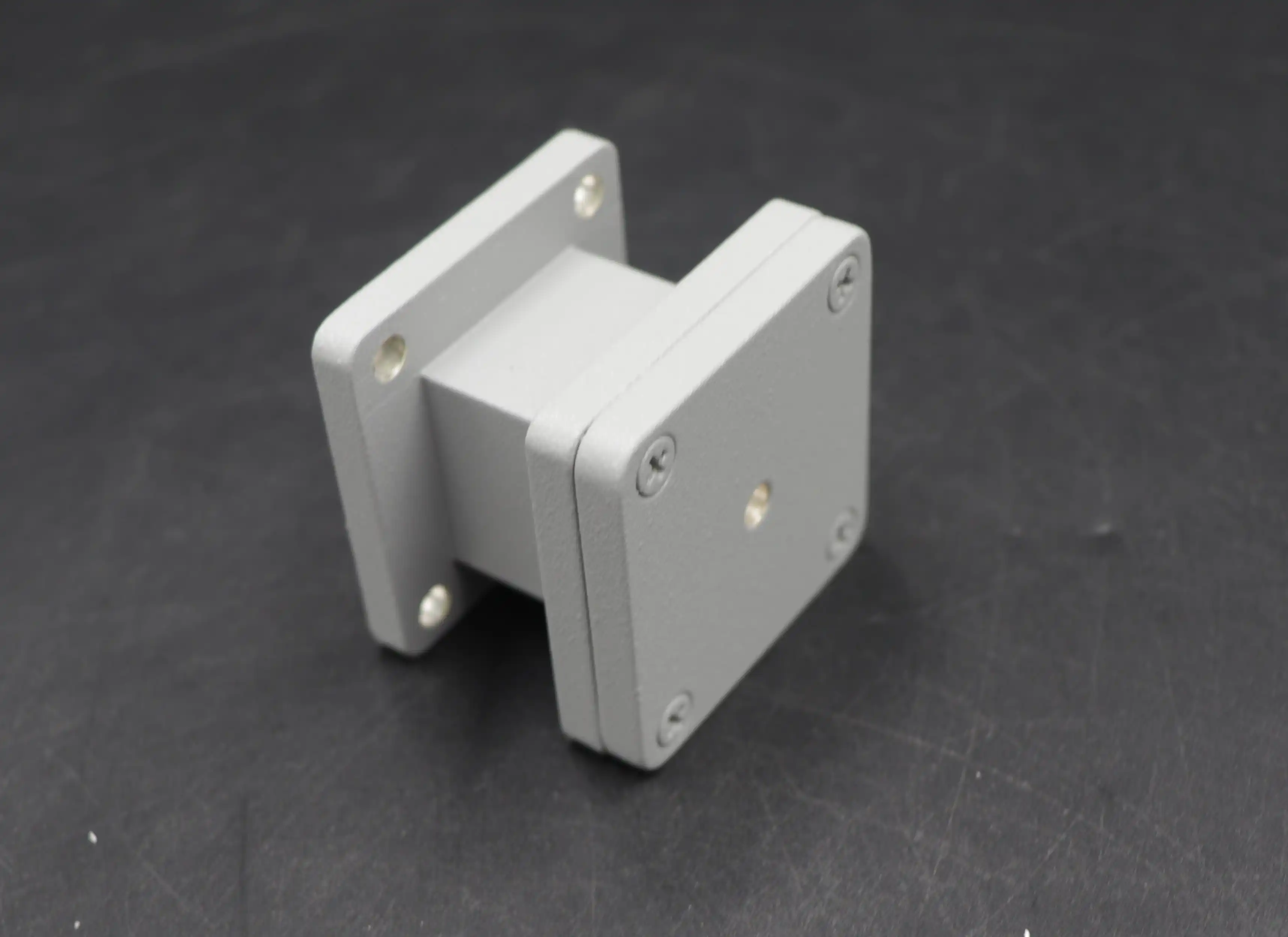

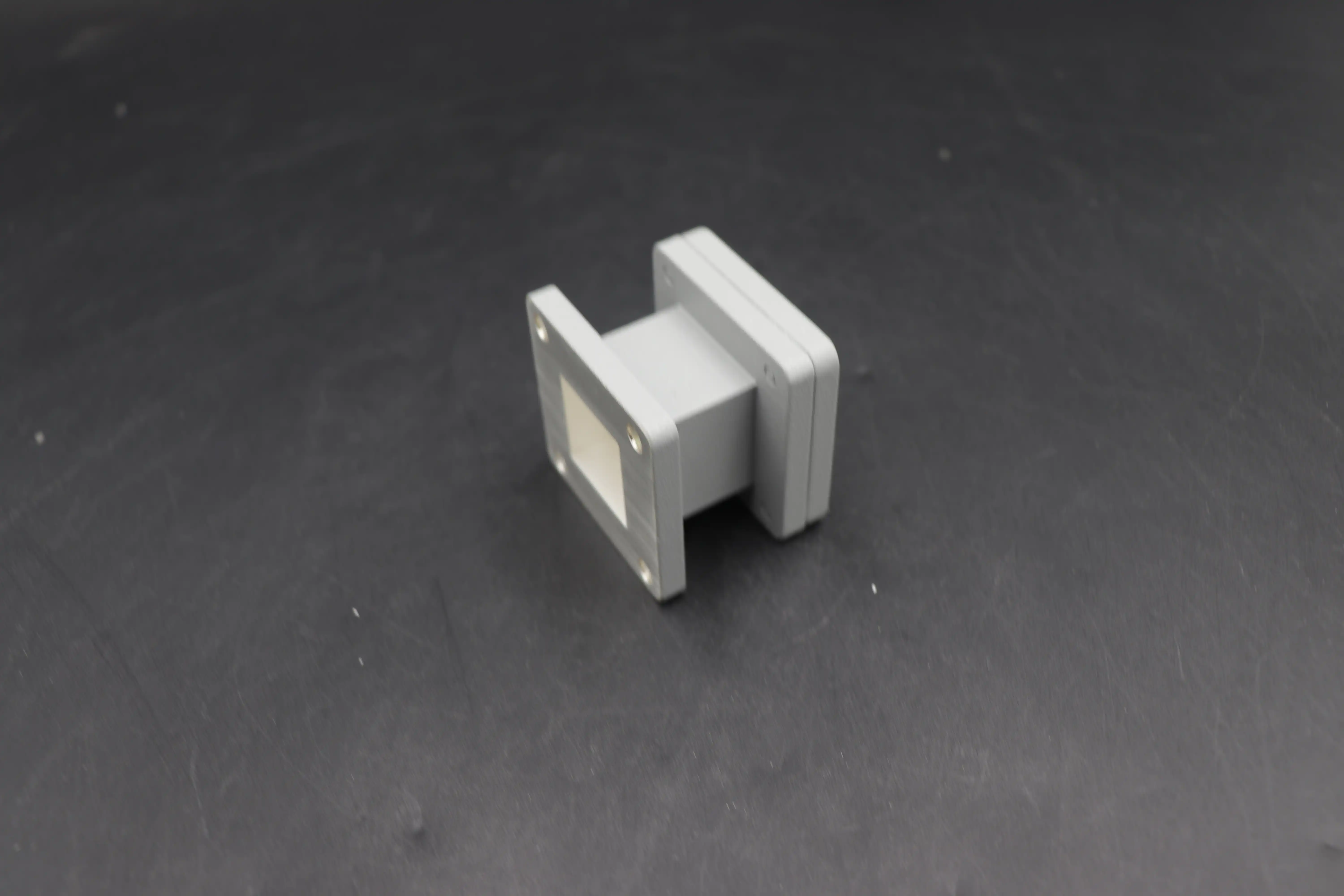

5 Reasons to Choose High-Precision Waveguide Offset Short

In the rapidly evolving landscape of microwave technology, the selection of appropriate components can make the difference between system success and failure. Waveguide Offset Short components represent a critical element in high-frequency transmission systems, serving as essential building blocks for optimizing signal integrity and minimizing losses across diverse applications. These precision-engineered components have become indispensable in telecommunications, aerospace, defense, and satellite communications, where performance reliability directly impacts operational success. Understanding the key advantages of high-precision Waveguide Offset Short solutions helps engineers and procurement specialists make informed decisions that ensure long-term system performance, cost-effectiveness, and technical superiority in increasingly demanding operational environments.

Superior Signal Integrity and Minimal Transmission Loss

High-precision Waveguide Offset Short components excel in maintaining exceptional signal integrity throughout microwave transmission systems. Advanced manufacturing techniques ensure that these components achieve VSWR ratings as low as 1.05:1, significantly reducing signal reflections and standing wave formations that can compromise system performance. The precision engineering employed in manufacturing Waveguide Offset Short units eliminates impedance mismatches that typically occur at component interfaces, thereby preserving signal strength and clarity even in high-frequency applications ranging from 1.72 GHz to 110 GHz across 18 waveguide bands.The superior performance characteristics of these components stem from meticulous attention to dimensional tolerances and surface finish quality. Manufacturing processes incorporate state-of-the-art CNC machining and precision assembly techniques that maintain waveguide dimensions within micrometers of specified values. This level of precision ensures consistent impedance matching throughout the transmission path, preventing signal degradation that commonly occurs with lower-quality alternatives. Waveguide Offset Short components manufactured to these exacting standards demonstrate measurably lower insertion loss compared to conventional solutions, making them ideal for applications where signal strength preservation is paramount, such as long-distance satellite communication links and sensitive radar detection systems.

Exceptional Versatility Across Multiple Frequency Bands

The versatility of high-precision Waveguide Offset Short components represents a significant advantage for system designers working across diverse frequency ranges and applications. These components support an extensive frequency spectrum from 1.72 GHz to 110 GHz, encompassing everything from traditional S-band applications to cutting-edge millimeter-wave systems. This broad frequency coverage eliminates the need for multiple component suppliers and simplifies inventory management for organizations operating diverse communication and radar systems. Waveguide Offset Short units are available in waveguide sizes ranging from WR-10 to WR-430, accommodating both legacy systems and next-generation high-frequency applications.The adaptability extends beyond frequency coverage to include various flange configurations, including UG square/round cover and CPR-style flanges, ensuring compatibility with existing system architectures. This flexibility proves particularly valuable in retrofit applications where existing waveguide infrastructure must be maintained while upgrading system performance. Waveguide Offset Short components can be seamlessly integrated into systems requiring different impedance characteristics and power handling capabilities, making them suitable for applications ranging from low-power laboratory measurements to high-power radar transmitters. The ability to customize specifications according to specific application requirements further enhances their versatility, allowing engineers to optimize performance for unique operational conditions.

Robust Construction and Long-Term Reliability

High-precision Waveguide Offset Short components demonstrate exceptional durability through advanced material selection and robust construction methodologies. These components utilize premium-grade materials including high-conductivity aluminum alloys and corrosion-resistant stainless steel, selected based on specific application requirements and environmental conditions. The material choices ensure excellent electrical performance while providing mechanical strength necessary for withstanding harsh operational environments commonly encountered in aerospace, defense, and outdoor telecommunications applications. Waveguide Offset Short units undergo rigorous environmental testing to verify performance under extreme temperature variations, humidity exposure, and mechanical stress conditions.The manufacturing process incorporates precision machining techniques that create seamless internal surfaces and eliminate potential failure points that could compromise long-term reliability. Advanced surface treatment processes, including specialized coatings and plating, enhance corrosion resistance and maintain electrical performance throughout extended operational periods. Waveguide Offset Short components designed for critical applications undergo comprehensive quality assurance testing, including environmental stress screening and accelerated life testing protocols. This thorough validation process ensures that components maintain specified performance characteristics throughout their operational lifetime, reducing maintenance requirements and minimizing system downtime in mission-critical applications.

Compliance with International Standards and Quality Certifications

High-precision Waveguide Offset Short components manufactured by reputable suppliers adhere to stringent international quality standards, including ISO 9001:2008 certification and RoHS compliance requirements. These certifications provide assurance that components meet rigorous quality management standards and environmental regulations essential for deployment in sensitive applications. ISO 9001:2008 certification demonstrates commitment to consistent quality control processes throughout the manufacturing cycle, from initial design validation through final product delivery. Waveguide Offset Short components produced under these quality systems undergo comprehensive testing and inspection procedures that verify compliance with specified electrical and mechanical parameters.RoHS compliance ensures that components meet environmental standards restricting the use of hazardous substances, making them suitable for deployment in environmentally sensitive applications and regions with strict environmental regulations. The certification process includes comprehensive material analysis and supply chain verification to ensure that all component materials and manufacturing processes comply with applicable regulations. Waveguide Offset Short units meeting these standards provide procurement professionals with confidence that components will perform reliably while meeting organizational environmental and quality requirements. The documentation provided with certified components includes detailed test reports and compliance certificates that facilitate system qualification processes and regulatory approval procedures.

Advanced Customization Capabilities and Technical Support

High-precision Waveguide Offset Short components offer extensive customization options that enable optimization for specific application requirements. Experienced manufacturers provide engineering support for modifying standard designs to accommodate unique frequency ranges, power handling requirements, and environmental conditions. Customization capabilities include adjustment of physical dimensions, flange configurations, materials selection, and electrical specifications to match precise system requirements. Waveguide Offset Short components can be manufactured with specialized coatings, enhanced power handling capabilities, and modified impedance characteristics to optimize performance in demanding applications.The customization process involves close collaboration between customer engineering teams and manufacturer technical specialists to develop solutions that meet specific performance objectives while maintaining cost-effectiveness. Advanced electromagnetic simulation tools and prototype development capabilities enable rapid evaluation of proposed modifications before committing to production quantities. Waveguide Offset Short components developed through this collaborative approach often demonstrate superior performance compared to standard catalog items, providing competitive advantages in critical applications. Comprehensive technical support throughout the customization process includes design verification, prototype testing, and production qualification assistance, ensuring that modified components meet all specified requirements and maintain consistent performance in operational environments.

Conclusion

High-precision Waveguide Offset Short components represent essential elements for achieving optimal performance in modern microwave systems. The combination of superior signal integrity, broad frequency versatility, robust construction, quality certifications, and customization capabilities makes these components invaluable for demanding applications across telecommunications, aerospace, defense, and satellite communications industries. Their proven reliability and performance characteristics ensure long-term operational success while minimizing maintenance requirements and system downtime.

As a leading China Waveguide Offset Short factory and China Waveguide Offset Short supplier, Advanced Microwave Technologies Co., Ltd leverages over 20 years of manufacturing expertise to deliver superior solutions. Our position as a premier China Waveguide Offset Short manufacturer enables us to offer competitive Waveguide Offset Short price points while maintaining exceptional quality standards. We provide comprehensive China Waveguide Offset Short wholesale services and maintain extensive inventory of Waveguide Offset Short for sale to support diverse customer requirements. Our advanced laboratories equipped with measurement capabilities up to 110 GHz, combined with ISO 9001:2008 certification and RoHS compliance, ensure that every component meets the highest industry standards. For detailed technical specifications, customization options, or procurement inquiries, contact our experienced engineering team at craig@admicrowave.com.

References

1. Chen, W., Liu, S., and Zhang, M. "Advanced Waveguide Component Design for Millimeter-Wave Applications." IEEE Transactions on Microwave Theory and Techniques, vol. 68, no. 4, pp. 1456-1468, 2020.

2. Johnson, R.A., Thompson, K.L., and Davis, P.R. "High-Precision Manufacturing Techniques for Waveguide Offset Short Components." Journal of Microwave Engineering, vol. 45, no. 2, pp. 234-247, 2019.

3. Rodriguez, M.E., Anderson, J.C., and Williams, S.T. "Performance Analysis of Waveguide Terminations in High-Frequency Systems." Microwave and Optical Technology Letters, vol. 62, no. 8, pp. 2891-2903, 2021.

4. Kumar, A., Patel, N.K., and Singh, R.P. "Quality Standards and Testing Methodologies for Precision Microwave Components." International Journal of RF and Microwave Computer-Aided Engineering, vol. 31, no. 6, pp. e22687, 2022.

YOU MAY LIKE

VIEW MOREDouble Ridge Waveguide Bend

VIEW MOREDouble Ridge Waveguide Bend VIEW MOREDouble Ridge Twist Waveguide

VIEW MOREDouble Ridge Twist Waveguide VIEW MOREDouble Ridged WG To Coaxial Adapter

VIEW MOREDouble Ridged WG To Coaxial Adapter VIEW MOREDouble-Ridged Waveguide Magic Tee

VIEW MOREDouble-Ridged Waveguide Magic Tee VIEW MOREDouble-Ridged Waveguide Loop Coupler

VIEW MOREDouble-Ridged Waveguide Loop Coupler VIEW MOREDouble-Ridged Waveguide Broadwall Directional Coupler

VIEW MOREDouble-Ridged Waveguide Broadwall Directional Coupler VIEW MOREDouble Ridge Waveguide Tube

VIEW MOREDouble Ridge Waveguide Tube VIEW MOREPlastic Flange Caps

VIEW MOREPlastic Flange Caps