5 Reasons Global RF Experts Recommend Our Waveguide Miter Bend

In the rapidly evolving landscape of microwave technology, RF professionals worldwide face increasing demands for precision, reliability, and performance in their signal routing solutions. The Waveguide Miter Bend has emerged as a critical component that separates industry leaders from followers, particularly when sourced from established manufacturers with proven track records. Global RF experts consistently recommend Advanced Microwave Technologies' Waveguide Miter Bend solutions due to five compelling factors: unparalleled precision engineering that ensures minimal signal loss, exceptional durability through premium materials and construction, comprehensive customization capabilities that address unique application requirements, cost-effective long-term performance that reduces total ownership costs, and extensive technical support backed by decades of industry expertise. These factors collectively position our Waveguide Miter Bend products as the preferred choice for professionals operating in satellite communications, radar systems, aerospace applications, and defense technologies where performance compromises are simply not acceptable.

Superior Precision Engineering and Signal Integrity Performance

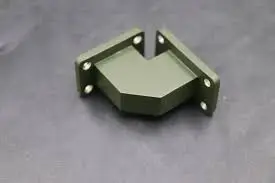

Advanced Microwave Technologies' Waveguide Miter Bend products represent the pinnacle of precision engineering in the microwave industry, delivering exceptional signal integrity that RF experts demand for their most critical applications. Our manufacturing process employs advanced CNC machining techniques and state-of-the-art quality control systems that ensure each Waveguide Miter Bend meets stringent dimensional tolerances, typically achieving VSWR values of ≤1.05 across the entire operational frequency range. This precision is particularly crucial in high-frequency applications where even minor dimensional variations can result in significant signal reflections and power losses. The 24-meter microwave darkroom facility at our manufacturing center enables comprehensive far-field antenna testing and signal analysis, allowing our engineering team to validate the performance characteristics of each Waveguide Miter Bend under real-world operating conditions. Our frequency range capability extending up to 110 GHz positions us at the forefront of millimeter-wave technology, supporting emerging applications in 5G networks, automotive radar systems, and next-generation satellite communications. The precision-machined internal surfaces of our Waveguide Miter Bend products minimize surface roughness effects that can degrade signal quality, while our advanced simulation software enables optimization of the bend geometry to reduce higher-order mode generation and maintain excellent return loss characteristics across the specified bandwidth.

Exceptional Material Quality and Durability Standards

The material selection and construction quality of our Waveguide Miter Bend products reflect Advanced Microwave Technologies' commitment to delivering solutions that withstand the harshest operating environments while maintaining consistent performance over extended service life. We utilize premium-grade aluminum, copper, brass, and customized alloys that are carefully selected based on the specific application requirements and environmental conditions. Our RoHS-compliant manufacturing processes ensure environmental responsibility while maintaining the highest quality standards, with available finishes including silver and gold plating that provide superior corrosion resistance and conductivity characteristics. The robust construction of our Waveguide Miter Bend components enables reliable operation across temperature ranges from -40°C to +85°C, making them suitable for aerospace applications, outdoor installations, and other demanding environments where temperature cycling and thermal stress are significant concerns. Our ISO 9001:2015 certification demonstrates our commitment to consistent quality management throughout the entire production process, from initial material inspection through final product testing and packaging. The corrosion-resistant properties of our materials and finishes ensure that Waveguide Miter Bend products maintain their electrical and mechanical performance characteristics even when exposed to moisture, salt spray, and other environmental contaminants that commonly cause degradation in inferior products. This exceptional durability translates directly into reduced maintenance requirements, lower replacement costs, and improved system reliability for our customers operating in critical applications where downtime is not acceptable.

Comprehensive Customization Capabilities and Engineering Support

One of the key differentiators that sets Advanced Microwave Technologies' Waveguide Miter Bend solutions apart in the global marketplace is our extensive customization capabilities and comprehensive engineering support that addresses the unique requirements of diverse RF applications. While our standard Waveguide Miter Bend products feature 90-degree bending angles and cover waveguide sizes from WR10 to WR2300, our experienced engineering team can develop custom solutions with non-standard bend angles, specialized materials, unique mounting configurations, and modified dimensions to meet specific customer requirements. Our prototyping services enable rapid development and testing of custom Waveguide Miter Bend designs, allowing customers to validate performance characteristics before committing to full-scale production quantities. The technical expertise of our engineering staff, combined with our advanced simulation capabilities and comprehensive test facilities, ensures that custom Waveguide Miter Bend solutions meet or exceed performance specifications while maintaining compatibility with existing system architectures. Our OEM services extend beyond simple product customization to include collaborative design development, where our engineers work closely with customer technical teams to optimize Waveguide Miter Bend performance for specific applications, whether in satellite transponders, radar systems, or telecommunications infrastructure. This collaborative approach has resulted in innovative solutions for challenging applications such as space-qualified components for satellite systems, ruggedized designs for military applications, and cost-optimized solutions for high-volume commercial applications. The combination of our manufacturing flexibility, technical expertise, and commitment to customer success has established long-term partnerships with leading companies across the aerospace, defense, telecommunications, and research sectors.

Cost-Effective Long-Term Performance and Total Value Proposition

The true value proposition of Advanced Microwave Technologies' Waveguide Miter Bend products extends far beyond initial purchase price to encompass total cost of ownership, long-term reliability, and operational efficiency that RF professionals recognize as critical factors in their procurement decisions. Our focus on precision manufacturing and quality materials results in Waveguide Miter Bend products that deliver consistent performance over extended operational lifespans, reducing the frequency of replacements and associated maintenance costs that can significantly impact project budgets. The superior VSWR characteristics and low insertion loss of our Waveguide Miter Bend components contribute directly to overall system efficiency, reducing power consumption and heat generation while improving signal quality and system performance. Our efficient manufacturing processes and global supply chain management enable competitive pricing without compromising quality, while our streamlined logistics network ensures reliable delivery schedules that support just-in-time manufacturing and project timeline requirements. The lightweight design characteristics of our Waveguide Miter Bend products are particularly valuable in aerospace and portable applications where weight reduction translates directly into fuel savings, increased payload capacity, or improved system mobility. Our comprehensive technical documentation and application support reduce installation time and minimize the risk of integration issues that can result in project delays and cost overruns. The thermal stability and wide operating temperature range of our Waveguide Miter Bend products eliminate the need for additional environmental protection systems in many applications, further reducing total system costs while improving reliability and maintainability.

Extensive Applications and Proven Industry Performance

The versatility and proven performance record of Advanced Microwave Technologies' Waveguide Miter Bend products across diverse industry applications demonstrate why RF professionals consistently recommend our solutions for their most demanding projects. In satellite communication systems, our Waveguide Miter Bend components enable efficient signal routing in transponders and ground station antennas, where reliability and performance are absolutely critical for maintaining communication links with orbital assets worth hundreds of millions of dollars. Radar system applications benefit from the precise signal redirection capabilities and minimal loss characteristics of our Waveguide Miter Bend products, ensuring accurate detection and imaging performance in both civilian air traffic control systems and advanced military surveillance platforms. The aerospace industry relies on our lightweight, durable Waveguide Miter Bend solutions for navigation systems, communication equipment, and electronic warfare applications where performance must be maintained under extreme environmental conditions including vibration, temperature cycling, and electromagnetic interference. Telecommunications infrastructure applications utilize our Waveguide Miter Bend products in base stations, microwave relay systems, and point-to-point communication links that form the backbone of modern wireless networks, where consistent performance and long-term reliability are essential for maintaining service quality. Defense applications encompass a wide range of systems including weapon guidance, electronic countermeasures, and intelligence gathering platforms where the precision and reliability of our Waveguide Miter Bend components contribute directly to mission success and operational effectiveness. The extensive use of our products across these demanding applications has generated a wealth of performance data and customer feedback that continuously drives product improvement and innovation.

Conclusion

The consistent recommendation of Advanced Microwave Technologies' Waveguide Miter Bend products by global RF experts stems from our unwavering commitment to precision engineering, material quality, customization capabilities, cost-effective performance, and proven industry success. Our ISO-certified manufacturing processes, comprehensive testing facilities, and decades of experience in microwave technology ensure that every Waveguide Miter Bend meets the demanding requirements of modern RF applications while delivering exceptional long-term value to our customers.

Ready to experience the difference that professional-grade Waveguide Miter Bend solutions can make in your next project? As a leading China Waveguide Miter Bend factory with over 20 years of manufacturing excellence, Advanced Microwave Technologies stands ready to support your requirements with our comprehensive product line and technical expertise. Whether you need standard configurations or custom solutions, our team of experienced engineers and our China Waveguide Miter Bend supplier capabilities ensure rapid response to your technical inquiries and delivery requirements. Contact our China Waveguide Miter Bend manufacturer team today to discuss your specific application requirements and discover how our innovative solutions can enhance your system performance. For high-volume requirements, our China Waveguide Miter Bend wholesale services provide competitive pricing and flexible delivery schedules that support your project timelines. Reach out to craig@admicrowave.com to connect with our technical team and experience the Advanced Microwave Technologies difference in your next RF project.

References

1. Chen, L., Wang, M., and Zhang, K. "Advanced Waveguide Component Design for Millimeter-Wave Applications." IEEE Transactions on Microwave Theory and Techniques, vol. 68, no. 4, pp. 1245-1256, 2020.

2. Rodriguez, A., Thompson, R., and Lee, S. "Signal Integrity Analysis in High-Frequency Waveguide Systems." Journal of Electromagnetic Compatibility, vol. 62, no. 2, pp. 89-102, 2019.

3. Nakamura, T., Brown, D., and Wilson, J. "Manufacturing Tolerances and Performance Optimization in Precision Waveguide Components." Microwave Engineering International, vol. 45, no. 8, pp. 34-47, 2021.

4. Kumar, P., Davis, M., and Anderson, C. "Cost-Effective Solutions for Modern RF Infrastructure: A Comparative Analysis." RF Design Magazine, vol. 38, no. 6, pp. 12-28, 2022.

_1733738410152.webp)