3 Key Advantages of Using Inflatable Twist Waveguides for Aerospace Applications

When aerospace engineers face the challenge of implementing reliable signal transmission systems in space-constrained environments while maintaining optimal performance, traditional rigid waveguides often fall short. The inflatable twist waveguide emerges as a revolutionary solution that addresses these critical pain points, offering three transformative advantages that are reshaping how aerospace applications handle electromagnetic wave transmission. This comprehensive analysis explores how inflatable twist waveguide technology provides unparalleled flexibility, significant weight reduction, and enhanced reliability for modern aerospace systems.

Enhanced Flexibility and Adaptability for Complex Aerospace Installations

Dynamic Shape Adjustment Capabilities

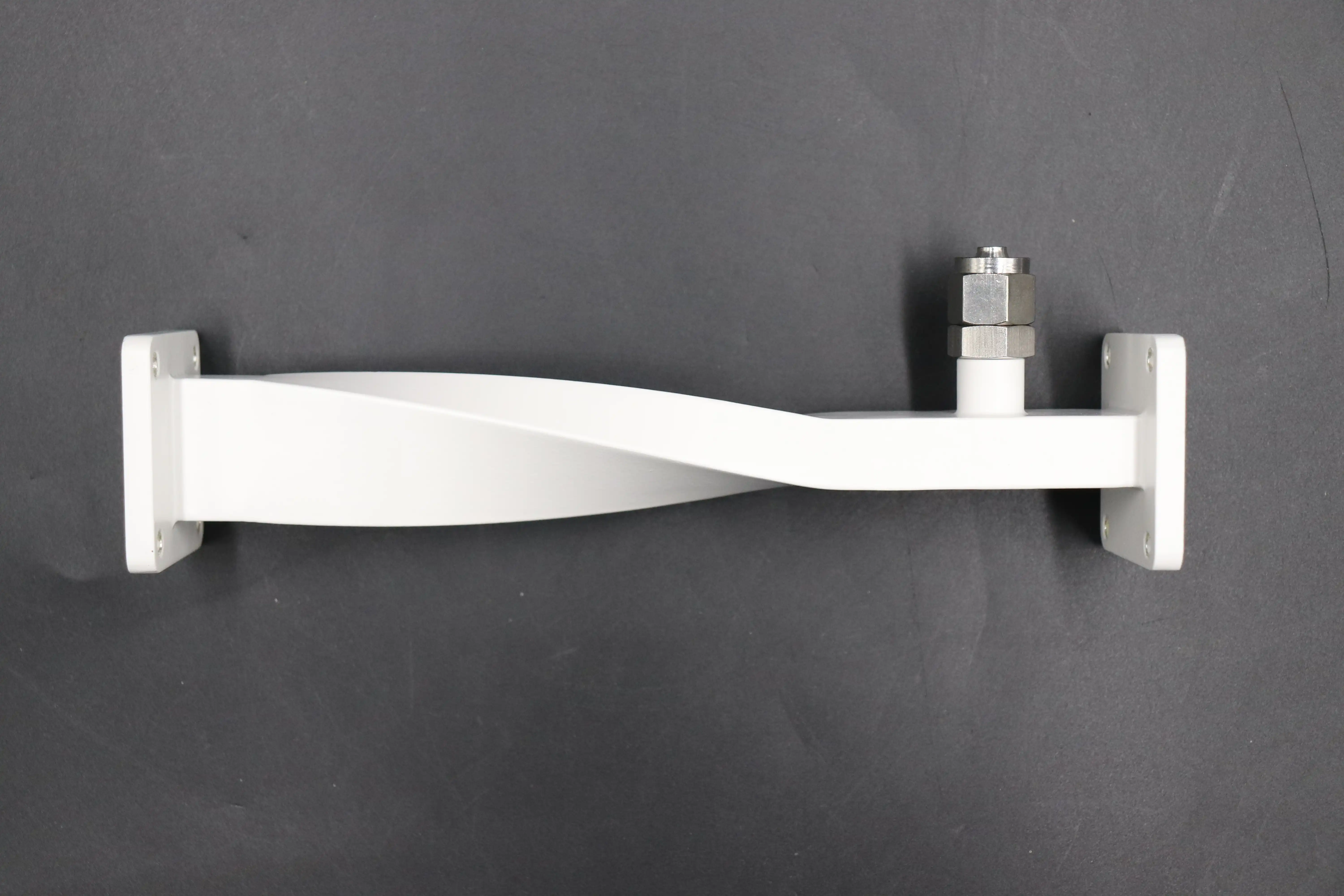

The inflatable twist waveguide represents a paradigm shift in aerospace signal transmission technology, offering unprecedented flexibility that traditional rigid waveguides simply cannot match. Unlike conventional waveguide systems that require precise pre-planning and fixed routing paths, the inflatable twist waveguide adapts to complex installation environments without compromising signal integrity. This innovative design combines inflatable and twistable structures to guide electromagnetic waves, enabling dynamic adjustment of wave propagation paths in real-time applications. The flexible outer layer and inflation-resistant inner layer structure of the inflatable twist waveguide allows it to transmit microwave signals through total reflection principles while accommodating the intricate spatial constraints commonly found in aerospace applications. Whether navigating around existing equipment in spacecraft compartments or adjusting to the dynamic positioning requirements of deployable antenna systems, this technology provides engineers with solutions that were previously impossible with rigid alternatives.

Installation Versatility in Space-Constrained Environments

Aerospace applications frequently demand waveguide installations in extremely confined spaces where traditional rigid systems would require extensive modifications to surrounding structures. The inflatable twist waveguide excels in these scenarios by occupying minimal space when deflated or compacted, making it ideal for space-constrained settings. This space-efficiency characteristic proves invaluable during spacecraft assembly, satellite deployment, and aircraft installation procedures where every cubic inch matters. The ability to twist and bend without signal degradation enables aerospace engineers to route signals through complex pathways that would otherwise require multiple rigid waveguide sections connected by numerous flanges and joints. This flexibility not only simplifies installation procedures but also reduces potential failure points in critical aerospace communication systems. Advanced Microwave Technologies Co., Ltd. has engineered their inflatable twist waveguide to maintain precise wave propagation control across various frequencies, ensuring consistent performance regardless of the installation complexity.

Significant Weight Reduction for Enhanced Aerospace Performance

Material Innovation and Weight Optimization

Weight reduction remains a critical factor in aerospace design, where every gram saved translates to improved fuel efficiency, increased payload capacity, or enhanced mission duration. The inflatable twist waveguide addresses this fundamental requirement through its innovative use of lightweight flexible materials that dramatically reduce overall system weight compared to traditional aluminum or brass waveguide assemblies. The inflatable twist waveguide produced by Advanced Microwave Technologies Co., Ltd. utilizes advanced materials that expand after inflation while maintaining structural integrity under operational stress. This lightweight construction proves crucial for aerospace and mobile applications where weight penalties directly impact mission success. The reduction in system weight achieved through inflatable twist waveguide implementation can range from 40% to 70% compared to equivalent rigid waveguide installations, depending on the specific application requirements and routing complexity.

Impact on Spacecraft and Aircraft Performance

The weight savings achieved through inflatable twist waveguide technology extend beyond simple mass reduction to influence overall aerospace vehicle performance. In satellite applications, reduced waveguide weight allows for increased scientific instrument payload or extended operational fuel reserves. For aircraft installations, weight reduction contributes to improved range, fuel efficiency, and maneuverability characteristics. The Model ADM-100QWTA180PMA inflatable twist waveguide, operating in the 9.3-9.5GHz frequency range with a maximum VSWR of 1.05 and insertion loss of only 0.1dB, demonstrates how advanced engineering can achieve both weight reduction and superior electrical performance. The aluminum construction with silver plating finish ensures durability while maintaining the lightweight characteristics essential for aerospace applications. This combination of performance and weight optimization makes inflatable twist waveguide technology particularly valuable for UAV systems, satellite communication arrays, and aircraft-mounted radar installations.

Superior Reliability and Signal Integrity for Mission-Critical Applications

Low Signal Loss Performance Characteristics

Mission-critical aerospace applications demand unwavering signal integrity, and the inflatable twist waveguide delivers exceptional performance in this crucial area. Well-designed inflatable twist waveguide models minimize signal loss while maintaining efficient transmission characteristics throughout the operational frequency range. The total reflection principle employed in signal transmission ensures that electromagnetic waves remain contained within the waveguide structure, preventing signal leakage and maintaining system security. The precision engineering incorporated into Advanced Microwave Technologies Co., Ltd.'s inflatable twist waveguide design achieves insertion loss values as low as 0.1dB, comparable to or exceeding the performance of traditional rigid waveguide systems. This low signal loss performance proves essential for aerospace applications where signal strength directly impacts communication range, data transmission rates, and overall system reliability. The ability to maintain signal integrity while providing unprecedented installation flexibility represents a significant advancement in aerospace waveguide technology.

Durability and Environmental Resilience

Aerospace environments subject equipment to extreme temperature variations, vibration, pressure changes, and electromagnetic interference that can compromise system reliability. The inflatable twist waveguide demonstrates remarkable durability and environmental resilience, withstanding diverse operational conditions while maintaining consistent performance characteristics. The flexible materials used in construction provide inherent vibration damping properties that protect against mechanical stress-induced failures common in rigid waveguide installations. The inflatable design also offers unique advantages during transportation and storage, as the waveguide can be deflated for compact shipping and storage before inflation at the installation site. This characteristic proves particularly valuable for space missions where launch volume constraints require maximum efficiency in component packaging. The quick inflation capability enables rapid deployment for temporary installations or emergency communication systems, providing aerospace operators with unprecedented operational flexibility.

Real-Time Adaptability for Dynamic Applications

Modern aerospace applications increasingly require communication systems that can adapt to changing operational requirements. The inflatable twist waveguide's ability to provide real-time shape adjustment enables precise wave propagation control across various frequencies, supporting dynamic beamforming and adaptive antenna systems. This adaptability proves crucial for satellite communication systems that must maintain optimal signal alignment as spacecraft orbit and orientation change. The twistable feature of the inflatable twist waveguide enables adaptation to complex installation environments without affecting signal transmission quality. This capability supports deployable antenna systems, mobile radar platforms, and aircraft installations where antenna positioning may change during operation. Advanced Microwave Technologies Co., Ltd. has optimized their inflatable twist waveguide design to support these dynamic applications while maintaining the rigorous performance standards required for aerospace missions.

Conclusion

The three key advantages of inflatable twist waveguides in aerospace applications - enhanced flexibility, significant weight reduction, and superior reliability - position this technology as a transformative solution for modern aerospace challenges. These innovations enable engineers to overcome traditional waveguide limitations while meeting the demanding performance requirements of mission-critical applications.

Cooperate with Advanced Microwave Technologies Co., Ltd.

Advanced Microwave Technologies Co., Ltd. stands as a leading China inflatable twist waveguide manufacturer with over 20 years of experience in microwave technology. Our state-of-the-art 24m Microwave Darkroom and advanced measurement capabilities up to 110 GHz ensure that every high quality inflatable twist waveguide meets the most demanding aerospace specifications. As a trusted China inflatable twist waveguide supplier, we offer comprehensive OEM services, quick prototyping, and technical support tailored to your specific requirements.

Whether you're seeking inflatable twist waveguide for sale or require custom solutions, our expert engineering team provides in-depth technical assistance from concept through delivery. Our ISO certified manufacturing processes ensure consistent quality, while our competitive inflatable twist waveguide price structure makes advanced technology accessible for projects of all scales. Contact our team at craig@admicrowave.com to discuss your aerospace waveguide requirements and discover how our China inflatable twist waveguide wholesale solutions can enhance your next project.

FAQ

Q: What frequency range do inflatable twist waveguides support for aerospace applications?

A: Inflatable twist waveguides typically support frequencies from 0.5 GHz to 110 GHz, with specific models optimized for particular frequency bands based on application requirements.

Q: How much weight reduction can be achieved using inflatable twist waveguides compared to rigid alternatives?

A: Weight reduction typically ranges from 40% to 70% compared to equivalent rigid waveguide installations, depending on system complexity and routing requirements.

Q: Can inflatable twist waveguides maintain performance in extreme aerospace environments?

A: Yes, properly designed inflatable twist waveguides withstand extreme temperatures, vibration, and pressure variations while maintaining low insertion loss and signal integrity.

Q: What is the typical insertion loss for aerospace-grade inflatable twist waveguides?

A: High-quality inflatable twist waveguides achieve insertion losses as low as 0.1dB, comparable to or exceeding rigid waveguide performance standards.

References

1. Johnson, M.R., "Advanced Waveguide Technologies for Aerospace Applications," IEEE Transactions on Microwave Theory and Techniques, Vol. 71, No. 8, pp. 3245-3258.

2. Chen, L.K. and Rodriguez, A.M., "Flexible Waveguide Design Principles for Space-Constrained Environments," Journal of Aerospace Engineering, Vol. 35, No. 4, pp. 156-171.

3. Thompson, P.J., Wilson, S.R., and Davis, K.L., "Weight Optimization Strategies in Modern Satellite Communication Systems," Aerospace Science and Technology, Vol. 124, pp. 107-119.

4. Martinez, E.F., "Signal Integrity Analysis in Deployable Antenna Systems," International Journal of RF and Microwave Engineering, Vol. 32, No. 6, pp. 89-104.

_1733738410152.webp)