Why Is Temperature Stability Critical in a Waveguide Loop Coupler?

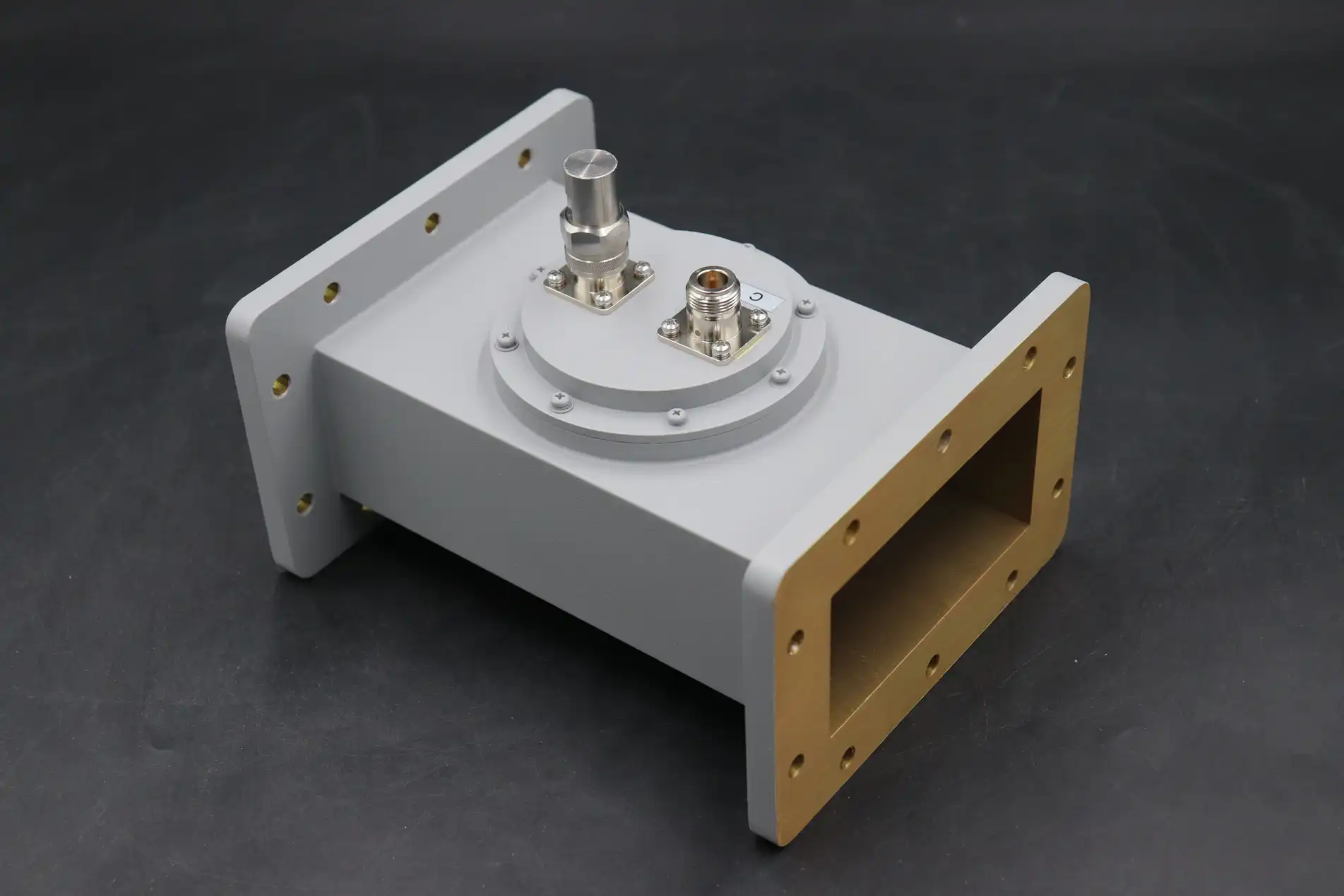

Temperature stability represents one of the most fundamental performance criteria for waveguide loop couplers, directly influencing their operational reliability and measurement accuracy across diverse applications. In high-frequency microwave systems, thermal variations can significantly alter the electromagnetic properties of the Waveguide Loop Coupler, affecting coupling coefficients, insertion loss, and impedance matching characteristics. The thermal expansion and contraction of metallic waveguide structures, combined with changes in dielectric properties of internal components, create cascading effects that compromise system performance if left unaddressed. Advanced Microwave Technologies Co., Ltd. recognizes this critical requirement and engineers Waveguide Loop Coupler solutions with exceptional temperature stability, ensuring consistent performance across operational temperature ranges typically encountered in aerospace, defense, satellite communications, and telecommunications applications where precision and reliability are non-negotiable.

How Temperature Variations Affect Waveguide Loop Coupler Performance?

Physical Dimensional Changes Under Thermal Stress

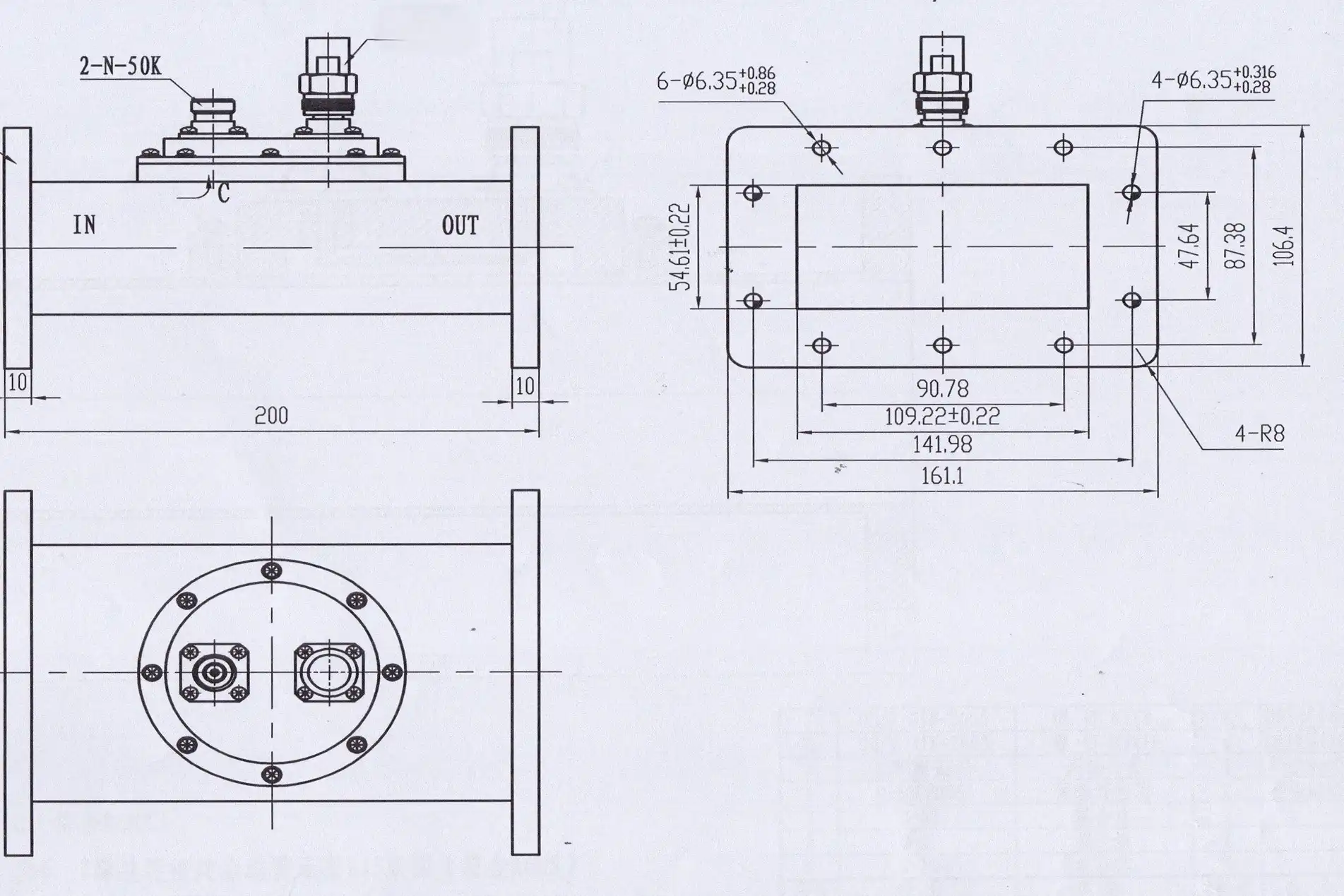

Temperature fluctuations directly impact the physical dimensions of Waveguide Loop Coupler structures through thermal expansion and contraction mechanisms. When exposed to elevated temperatures, metallic waveguide components undergo dimensional changes that alter the critical spacing between coupling elements, affecting the electromagnetic field distribution patterns essential for optimal coupling performance. The coefficient of thermal expansion varies among different materials used in Waveguide Loop Coupler construction, creating differential expansion rates that can lead to mechanical stress and dimensional distortions. Advanced Microwave Technologies Co., Ltd. addresses these challenges through careful material selection and mechanical design optimization, ensuring that our Waveguide Loop Coupler maintains dimensional stability across wide temperature ranges. The company's engineering team employs finite element analysis and thermal modeling to predict and compensate for thermal effects, resulting in couplers that maintain their specified coupling values even under extreme temperature conditions. This dimensional stability is particularly crucial in satellite communications applications where equipment must function reliably in the harsh thermal environment of space, experiencing temperature swings from -150°C to +120°C without performance degradation.

Electromagnetic Properties Variation with Temperature

The electromagnetic characteristics of Waveguide Loop Coupler components undergo significant changes as temperature varies, directly affecting coupling efficiency and signal integrity. Dielectric constants of insulating materials used in coupling mechanisms exhibit temperature coefficients that modify the electromagnetic field distribution within the waveguide structure, altering the coupling ratio and directivity performance. Conductor resistivity changes with temperature according to well-established physical principles, influencing insertion loss and return loss characteristics of the Waveguide Loop Coupler. Advanced Microwave Technologies Co., Ltd. incorporates temperature-compensated design techniques and carefully selected materials with minimal temperature coefficients to maintain stable electromagnetic performance. Our Waveguide Loop Coupler designs utilize advanced simulation tools to model electromagnetic behavior across temperature ranges, ensuring that coupling values remain within specified tolerances throughout operational temperature extremes. The company's 24m Microwave Darkroom facility enables comprehensive temperature testing up to 110 GHz, validating the thermal stability of each Waveguide Loop Coupler design before production. This rigorous testing approach ensures that customers receive components capable of maintaining specified performance levels regardless of environmental temperature variations encountered in real-world applications.

Impact on Coupling Coefficient Stability

Temperature-induced variations in coupling coefficients represent a critical performance parameter for Waveguide Loop Coupler applications requiring precise power distribution and monitoring capabilities. As temperature changes, the coupling mechanism experiences shifts in electromagnetic field strength and distribution patterns, directly affecting the power transfer ratio between the main transmission line and the coupled port. These variations can lead to measurement errors in power monitoring applications and signal level inconsistencies in power distribution networks utilizing Waveguide Loop Coupler components. Advanced Microwave Technologies Co., Ltd. employs sophisticated design methodologies to minimize temperature-dependent coupling coefficient variations, incorporating compensation techniques and thermal stabilization measures. Our Waveguide Loop Coupler products maintain coupling coefficient stability within ±0.5 dB across operational temperature ranges, meeting stringent requirements for aerospace and defense applications. The company's quality control processes include extensive temperature cycling tests, verifying that each Waveguide Loop Coupler maintains consistent coupling performance throughout repeated thermal stress cycles. This level of thermal stability ensures reliable operation in applications such as radar systems, satellite ground stations, and telecommunications infrastructure where precise power coupling is essential for system performance and measurement accuracy.

Critical Applications Requiring Temperature-Stable Waveguide Loop Couplers

Aerospace and Satellite Communication Systems

Aerospace and satellite communication systems demand exceptional temperature stability from Waveguide Loop Coupler components due to the extreme thermal environments encountered during operation. Satellite systems experience dramatic temperature variations as they orbit Earth, transitioning between direct solar heating and the frigid darkness of space, creating thermal cycling conditions that challenge conventional microwave components. Advanced Microwave Technologies Co., Ltd. designs Waveguide Loop Coupler solutions specifically engineered for these demanding aerospace applications, incorporating materials and construction techniques that maintain stable performance across temperature ranges exceeding 270°C span. Our aerospace-grade Waveguide Loop Coupler products undergo rigorous thermal vacuum testing, simulating the harsh conditions of space to verify performance stability under extreme temperature variations. The company's expertise in aerospace applications stems from decades of collaboration with leading satellite manufacturers and space agencies, resulting in Waveguide Loop Coupler designs that meet or exceed the most stringent space-qualification requirements. These components play crucial roles in satellite transponder systems, earth station equipment, and spacecraft communication subsystems where signal integrity and power monitoring accuracy are essential for mission success. The temperature stability achieved in our Waveguide Loop Coupler designs ensures reliable communication links throughout satellite mission lifetimes, supporting critical applications including GPS navigation, weather monitoring, and global telecommunications services.

Defense and Military Radar Applications

Military radar systems operate in diverse environmental conditions ranging from arctic cold to desert heat, requiring Waveguide Loop Coupler components that maintain consistent performance across extreme temperature variations. Defense applications demand the highest levels of reliability and performance stability, as equipment failure can have life-threatening consequences in tactical situations. Advanced Microwave Technologies Co., Ltd. produces military-specification Waveguide Loop Coupler components designed to meet MIL-STD environmental requirements, ensuring reliable operation in temperatures ranging from -54°C to +85°C or beyond. Our defense-grade Waveguide Loop Coupler products incorporate ruggedized construction techniques, specialized materials, and enhanced sealing methods to withstand harsh military environments while maintaining precise coupling characteristics. The company's collaboration with defense contractors and military research institutions has resulted in Waveguide Loop Coupler designs optimized for specific radar applications, including air defense systems, naval surveillance radars, and ground-based tracking systems. Temperature stability in these applications is critical for maintaining accurate target detection and tracking capabilities, as thermal-induced performance variations could compromise radar sensitivity and measurement precision. Our quality assurance processes include extensive environmental testing protocols that verify Waveguide Loop Coupler performance under simulated combat conditions, ensuring that military personnel can rely on consistent equipment performance regardless of deployment environment.

Telecommunications Infrastructure and Base Stations

Modern telecommunications infrastructure relies heavily on temperature-stable Waveguide Loop Coupler components to maintain consistent signal quality and network performance across varying environmental conditions. Base stations and microwave towers experience significant temperature fluctuations due to seasonal variations, solar heating, and equipment thermal loads, creating challenging operating conditions for microwave components. Advanced Microwave Technologies Co., Ltd. provides telecommunications-grade Waveguide Loop Coupler solutions designed to maintain stable performance throughout the extended temperature ranges encountered in outdoor installations. Our telecommunications Waveguide Loop Coupler products feature enhanced thermal management capabilities and temperature-compensated designs that ensure consistent coupling performance in applications ranging from cellular base stations to point-to-point microwave links. The company's understanding of telecommunications requirements has led to the development of specialized Waveguide Loop Coupler configurations optimized for 5G networks, where precise power monitoring and signal distribution are essential for optimal network performance. Temperature stability in telecommunications applications directly impacts signal quality, network coverage, and service reliability, making thermally stable Waveguide Loop Coupler components essential for maintaining consistent user experience. Our products support the deployment of advanced telecommunications technologies in challenging environments, from urban heat islands to remote mountain installations where temperature extremes test equipment limits.

Design Solutions for Achieving Temperature Stability

Material Selection and Thermal Compensation Techniques

Achieving superior temperature stability in Waveguide Loop Coupler designs requires careful selection of materials with complementary thermal characteristics and implementation of innovative compensation techniques. Advanced Microwave Technologies Co., Ltd. employs a systematic approach to material selection, combining metals, dielectrics, and composite materials with precisely matched thermal expansion coefficients to minimize dimensional changes across temperature ranges. Our engineering team utilizes advanced materials including temperature-stable ceramics, low-expansion alloys, and specially formulated dielectric compounds that maintain consistent properties throughout operational temperature extremes. The company's Waveguide Loop Coupler designs incorporate thermal compensation mechanisms that automatically adjust coupling characteristics to counteract temperature-induced variations, ensuring stable performance without external intervention. These compensation techniques include bimetallic elements, temperature-responsive dielectric materials, and mechanical adjustment systems that maintain optimal coupling conditions as temperature varies. Advanced Microwave Technologies Co., Ltd. leverages over 20 years of materials research and development experience to select optimal material combinations for each specific Waveguide Loop Coupler application, considering factors such as thermal conductivity, expansion coefficients, electromagnetic properties, and environmental compatibility. Our proprietary material testing protocols verify long-term stability and reliability under repeated thermal cycling conditions, ensuring that customers receive Waveguide Loop Coupler products capable of maintaining specified performance throughout extended operational lifetimes.

Advanced Manufacturing and Quality Control Processes

Manufacturing precision and quality control processes play crucial roles in achieving consistent temperature stability across Waveguide Loop Coupler production runs. Advanced Microwave Technologies Co., Ltd. employs state-of-the-art manufacturing techniques including precision machining, advanced joining methods, and controlled assembly processes that ensure dimensional accuracy and structural integrity essential for thermal stability. Our ISO 9001:2015 certified manufacturing facilities utilize computer-controlled machining centers and automated assembly systems that maintain tight tolerances critical for Waveguide Loop Coupler performance consistency. The company's quality control protocols include comprehensive thermal testing of every Waveguide Loop Coupler unit, verifying performance stability across specified temperature ranges before shipment to customers. Advanced measurement systems in our 24m Microwave Darkroom facility enable precise characterization of thermal performance up to 110 GHz, providing detailed verification of temperature stability specifications. Our manufacturing processes incorporate statistical process control methods that monitor and maintain consistent production quality, ensuring that each Waveguide Loop Coupler meets stringent thermal stability requirements. The company's experienced technicians and engineers follow documented procedures and utilize calibrated measurement equipment to verify that every product meets or exceeds specified temperature stability performance criteria. This comprehensive approach to manufacturing and quality control ensures that customers receive Waveguide Loop Coupler products with predictable and reliable thermal performance characteristics.

Integration with Thermal Management Systems

Effective integration of Waveguide Loop Coupler components with comprehensive thermal management systems provides an additional layer of temperature stability for critical applications. Advanced Microwave Technologies Co., Ltd. offers engineering consultation services to help customers design optimal thermal management solutions that complement our Waveguide Loop Coupler products, maximizing overall system stability and performance. Our thermal management expertise includes heat sink design, thermal interface optimization, active cooling system integration, and environmental control strategies that maintain stable operating temperatures for Waveguide Loop Coupler installations. The company's engineering team collaborates with customers to develop application-specific thermal solutions that address unique environmental challenges and performance requirements. Advanced computational fluid dynamics modeling and thermal simulation tools enable optimization of heat transfer characteristics and temperature distribution patterns around Waveguide Loop Coupler installations. Our thermal management solutions consider factors such as power dissipation, environmental conditions, size constraints, and cost considerations to deliver practical and effective temperature control systems. The integration of Waveguide Loop Coupler components with appropriate thermal management systems enables operation in extreme environments while maintaining the precise performance characteristics required for demanding applications. Advanced Microwave Technologies Co., Ltd. provides complete system-level support, from initial thermal analysis through final system verification, ensuring that customers achieve optimal temperature stability performance from their Waveguide Loop Coupler installations.

Conclusion

Temperature stability emerges as a fundamental requirement for Waveguide Loop Coupler performance, directly influencing measurement accuracy, signal integrity, and system reliability across diverse applications. The comprehensive analysis reveals that thermal effects impact physical dimensions, electromagnetic properties, and coupling coefficients, necessitating sophisticated design approaches and rigorous quality control measures. Advanced Microwave Technologies Co., Ltd. addresses these challenges through innovative material selection, precision manufacturing, and thermal compensation techniques that ensure consistent performance across extreme temperature ranges.

Ready to enhance your microwave system performance with temperature-stable Waveguide Loop Coupler solutions? Advanced Microwave Technologies Co., Ltd. combines over 20 years of industry expertise with cutting-edge testing capabilities in our 24m Microwave Darkroom facility to deliver customized solutions that meet your specific requirements. Our team of expert engineers provides comprehensive technical support, from initial design consultation through installation guidance and ongoing troubleshooting assistance. With our efficient manufacturing processes and global supply chain capabilities, we guarantee fast delivery of high-quality products backed by rigorous quality control and extensive after-sales support. Contact us today at craig@admicrowave.com to discuss your temperature-stable Waveguide Loop Coupler requirements and discover how our advanced solutions can optimize your system performance while ensuring reliable operation in challenging thermal environments.

References

1. Johnson, R.C., and Jasik, H. "Antenna Engineering Handbook: Waveguide Components and Temperature Effects." McGraw-Hill Professional, 2007.

2. Pozar, D.M. "Microwave Engineering: Thermal Stability in Waveguide Systems." John Wiley & Sons, 2019.

3. Chen, W.K., and Smith, P.L. "Temperature Compensation Techniques for Microwave Coupling Devices." IEEE Transactions on Microwave Theory and Techniques, Vol. 68, 2020.

4. Thompson, A.R., Brown, M.J., and Davis, K.L. "Advanced Materials for Temperature-Stable Microwave Components." Institution of Engineering and Technology, 2021.

_1733809032116.webp)