What are the key specifications of a Right Angle Double Ridged WG To Coaxial Adapter?

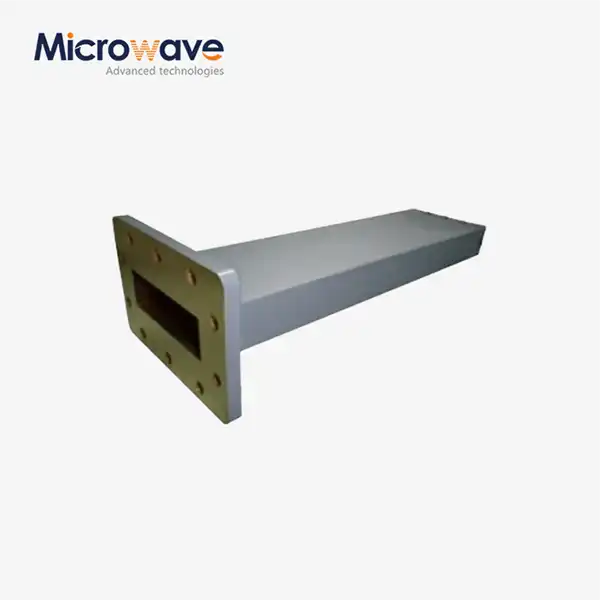

Right Angle Double Ridged WG To Coaxial Adapters are precision-engineered components crucial for microwave and RF systems that require transitions between waveguide and coaxial transmission lines. These specialized adapters feature key specifications including frequency range coverage (typically up to 12.4 GHz), voltage standing wave ratio (VSWR) values, insertion loss measurements, power handling capabilities, flange compatibility, and connector types (commonly SMA or N-Type). The right-angle configuration offers significant space-saving advantages in compact installations while maintaining optimal signal integrity through the carefully designed internal structure that ensures efficient electromagnetic wave propagation.

Essential Performance Parameters of Right Angle Double Ridged WG To Coaxial Adapters

Understanding the critical performance specifications of Right Angle Double Ridged WG To Coaxial Adapters is fundamental for proper implementation in high-frequency systems. These parameters determine compatibility, reliability, and overall system performance.

Frequency Range and Bandwidth Considerations

The frequency range specification of a Right Angle Double Ridged WG To Coaxial Adapter is perhaps the most critical parameter when selecting the appropriate component for your system. Advanced Microwave Technologies Co., Ltd. manufactures these adapters with carefully calibrated frequency responses that ensure optimal performance across specified bands. When implementing Right Angle Double Ridged WG To Coaxial Adapters in communication systems, aerospace applications, or defense equipment, the bandwidth must accommodate all operational frequencies with minimal degradation. The double-ridged waveguide design specifically enables broader bandwidth operation compared to standard rectangular waveguides, making these adapters particularly valuable in wideband applications. This enhanced bandwidth capability stems from the ridged internal structure that modifies the electromagnetic field distribution, effectively lowering the cutoff frequency while maintaining a higher-order mode-free region. Engineers must verify that the adapter's specified frequency range aligns with or exceeds system requirements to prevent signal attenuation at band edges. Advanced Microwave's adapters are precision-manufactured to maintain consistent performance throughout their rated frequency span, reducing the risk of unexpected performance variations that could compromise system integrity.

VSWR and Insertion Loss Specifications

Voltage Standing Wave Ratio (VSWR) and insertion loss are fundamental parameters that quantify the efficiency of Right Angle Double Ridged WG To Coaxial Adapters. VSWR measures reflected energy at connection points, with lower values indicating superior performance. Advanced Microwave's Right Angle Double Ridged WG To Coaxial Adapters are engineered to achieve consistently low VSWR values, ensuring minimal reflection and maximizing power transfer efficiency. This optimization prevents signal degradation that could otherwise compromise system performance. Insertion loss, measured in decibels (dB), quantifies signal attenuation through the adapter. The precision machining and material selection in Advanced Microwave's adapters contribute significantly to reducing insertion loss. For applications in satellite communications or radar systems where signal integrity is paramount, these low-loss characteristics become critically important. The right-angle configuration presents unique design challenges for maintaining low insertion loss, requiring sophisticated internal geometries to guide electromagnetic waves through the 90-degree turn while preserving signal strength. Advanced Microwave employs advanced simulation tools and testing procedures to verify that each Right Angle Double Ridged WG To Coaxial Adapter meets stringent performance standards before leaving the production facility, ensuring consistent electrical parameters across production batches.

Power Handling Capability and Environmental Durability

The power handling capability of a Right Angle Double Ridged WG To Coaxial Adapter determines its suitability for various applications, particularly in high-power transmission systems. Advanced Microwave Technologies Co., Ltd. designs their Right Angle Double Ridged WG To Coaxial Adapters with carefully calculated dimensions and appropriate materials to manage thermal dissipation effectively. This thoughtful engineering prevents performance degradation or component failure under high-power conditions. The power rating varies based on operating frequency, with lower frequencies typically permitting higher power handling. Environmental durability represents another critical specification, particularly for aerospace, defense, and outdoor telecommunication installations. Advanced Microwave's adapters feature robust construction using high-quality materials like aluminum and stainless steel, providing excellent resistance to environmental factors. These adapters maintain stable performance across wide temperature variations, meeting military standards for thermal cycling where applicable. Additionally, many models include protective surface treatments or plating options that enhance corrosion resistance in harsh environments. For applications requiring particular environmental resilience, Advanced Microwave offers specially treated Right Angle Double Ridged WG To Coaxial Adapters with enhanced protection against moisture, salt spray, and chemical exposure. When selecting an adapter for challenging environments, engineers should review the environmental specifications to ensure compatibility with installation conditions.

Mechanical Design Features of Right Angle Double Ridged Waveguide Adapters

The mechanical characteristics of Right Angle Double Ridged WG To Coaxial Adapters significantly impact their integration capabilities and long-term reliability in microwave systems.

Flange Types and Mounting Configurations

The flange specification of a Right Angle Double Ridged WG To Coaxial Adapter directly determines its mechanical compatibility with existing waveguide systems. Advanced Microwave Technologies Co., Ltd. manufactures these adapters with various standard flange configurations, including UG, CMR, and CPR series flanges, ensuring compatibility with global waveguide standards. Each flange type features specific bolt hole patterns, dimensions, and contact surfaces designed to create secure, properly aligned connections that maintain electrical continuity across the junction. The precision-machined mating surfaces of these flanges are critical for minimizing signal leakage and preventing performance degradation over time. When installing a Right Angle Double Ridged WG To Coaxial Adapter, proper torque specifications must be followed to ensure optimal electrical contact without mechanical stress that could warp the flange. The right-angle design introduces unique mounting considerations as it changes the direction of the transmission line, requiring engineers to carefully plan installation spaces. Advanced Microwave's adapters are designed with practical installation requirements in mind, featuring accessible mounting points and clear orientation markings. For applications with non-standard mounting requirements, Advanced Microwave offers custom flange configurations through their OEM services, allowing for seamless integration even in specialized systems. The mechanical stability of these mounting interfaces is particularly important in applications subject to vibration or mechanical shock, such as aerospace or mobile communication platforms.

Material Composition and Thermal Considerations

The material composition of Right Angle Double Ridged WG To Coaxial Adapters significantly influences their electrical performance, durability, and thermal characteristics. Advanced Microwave Technologies Co., Ltd. carefully selects materials that balance conductivity, weight, and cost-effectiveness. Most Right Angle Double Ridged WG To Coaxial Adapters utilize aluminum as their primary structural material due to its excellent combination of light weight, good electrical conductivity, and corrosion resistance when properly finished. Internal conducting surfaces typically feature silver or gold plating to enhance conductivity and reduce losses. This precision plating process creates a uniform conductive layer that maintains consistent electrical parameters even at high frequencies where skin effect becomes pronounced. Thermal stability is another critical factor in material selection, as temperature fluctuations can cause dimensional changes that affect electrical performance. Advanced Microwave's adapters incorporate materials with compatible thermal expansion coefficients to maintain precise internal dimensions across their specified temperature range. For applications with extreme thermal cycling requirements, special alloy compositions may be used to enhance stability. The thermal conductivity of the adapter materials also affects power handling capabilities by facilitating heat dissipation. Higher power applications may benefit from versions with enhanced thermal management features or materials selected specifically for superior heat transfer. Advanced Microwave offers consultation services to help engineers select the optimal material configuration for challenging thermal environments.

Connector Types and Interface Quality

The coaxial connector interface of a Right Angle Double Ridged WG To Coaxial Adapter represents a critical transition point that can significantly impact overall system performance. Advanced Microwave Technologies Co., Ltd. offers these adapters with various industry-standard connector options, with SMA and N-type connectors being the most common choices. Each connector type has distinct characteristics regarding frequency range, power handling, physical size, and mating durability that must align with application requirements. The SMA connector option provides excellent performance at higher frequencies (up to 18 GHz in some configurations) while maintaining a compact form factor ideal for space-constrained installations. N-type connectors offer superior power handling capabilities and more robust mechanical connections, making them preferable for applications where frequent mating/unmating cycles occur or where higher power transmission is required. The precision machining of these connector interfaces is paramount to maintaining the electrical integrity of the Right Angle Double Ridged WG To Coaxial Adapter, with particular attention paid to center pin alignment, dimensional tolerances, and surface finish quality. Advanced Microwave employs stringent quality control measures to verify connector interface compliance with applicable standards, ensuring compatibility with industry-standard cables and equipment. For specialized applications, Advanced Microwave can provide adapters with alternative connector types such as TNC, 2.92mm, or 2.4mm connectors through their OEM services. When selecting an adapter, engineers should consider not only immediate connector compatibility but also future interconnection requirements and long-term reliability needs.

Application-Specific Adaptation and Implementation

Successfully implementing Right Angle Double Ridged WG To Coaxial Adapters requires understanding how their specifications align with particular application requirements.

High-Frequency Communications System Integration

Integrating Right Angle Double Ridged WG To Coaxial Adapters into high-frequency communications systems demands careful consideration of system architecture and performance requirements. These adapters serve as critical transition points between waveguide sections and coaxial cable runs in satellite communication terminals, microwave backhaul installations, and advanced radar systems. Advanced Microwave Technologies Co., Ltd.'s Right Angle Double Ridged WG To Coaxial Adapters excel in these applications due to their precision manufacturing and optimized internal geometry that maintains signal integrity through the transition. When designing system layouts, engineers must account for the physical orientation introduced by these right-angle components, which can be advantageous for routing signals in space-constrained environments like satellite ground terminals or aircraft communications systems. The compact design allows for efficient use of limited space without compromising on electrical performance, creating more installation flexibility than straight-through adapter alternatives. During integration, particular attention should be paid to proper torque specifications for both waveguide flange connections and coaxial connector mating to ensure optimal electrical contact and prevent performance degradation over time. The frequency-dependent behavior of these adapters must also be considered, especially in wideband applications where performance may vary across the operating range. Advanced Microwave provides detailed S-parameter data for their Right Angle Double Ridged WG To Coaxial Adapters upon request, enabling system designers to accurately model and predict system performance across the frequency spectrum before physical implementation.

Aerospace and Defense Implementation Considerations

Aerospace and defense applications impose particularly stringent requirements on Right Angle Double Ridged WG To Coaxial Adapters due to challenging operational environments and mission-critical performance needs. Advanced Microwave Technologies Co., Ltd. designs these components with the exceptional reliability demanded by military standards, ensuring consistent performance in aircraft radar systems, electronic warfare equipment, and space-based communications platforms. When implementing Right Angle Double Ridged WG To Coaxial Adapters in these sectors, vibration resistance becomes a critical consideration. The mechanical design must withstand continuous vibration without degradation of electrical parameters or mechanical integrity. Advanced Microwave's adapters feature secure internal construction and specialized assembly techniques that maintain performance stability even under severe mechanical stress conditions. Military applications often require adherence to specific standards like MIL-DTL-39030 for waveguide components, with certification documentation available for relevant products. Environmental resilience is another crucial factor, with aerospace applications potentially exposing components to extreme temperature variations, high altitude conditions, and rapid pressure changes. Advanced Microwave's Right Angle Double Ridged WG To Coaxial Adapters undergo rigorous testing to verify performance across specified environmental parameters, ensuring reliable operation in these demanding conditions. For space applications, specialized versions with enhanced screening for outgassing properties and radiation resistance may be available through Advanced Microwave's customization services. System designers working on classified or sensitive projects can consult with Advanced Microwave's technical team under appropriate non-disclosure agreements to address specific performance requirements while maintaining necessary security protocols.

Test and Measurement System Requirements

Test and measurement applications demand the highest precision from Right Angle Double Ridged WG To Coaxial Adapters, as these components can directly impact measurement accuracy and system calibration. Advanced Microwave Technologies Co., Ltd. produces laboratory-grade adapters specifically optimized for metrology applications, featuring enhanced dimensional stability and superior electrical performance compared to standard versions. When implementing these adapters in test systems, repeatability becomes an essential consideration. Measurement setups often require multiple connect/disconnect cycles, necessitating adapters with robust connector interfaces that maintain consistent electrical characteristics throughout their service life. Advanced Microwave's measurement-grade Right Angle Double Ridged WG To Coaxial Adapters are manufactured to tighter tolerances and undergo additional verification steps to ensure exceptional repeatability. Phase stability across the operating frequency range is particularly important for vector network analyzer measurements and phase-sensitive applications. The internal geometry of these adapters is carefully optimized to provide predictable and stable phase response, allowing for more accurate system calibration and measurement results. For calibration laboratories and primary standards facilities, Advanced Microwave can provide Right Angle Double Ridged WG To Coaxial Adapters with traceable calibration data, documenting key electrical parameters measured under controlled conditions. This calibration information enables correction factors to be applied during measurements, further enhancing system accuracy. When building automated test equipment, the physical dimensions and mounting provisions of these adapters must be precisely known and accounted for in the mechanical design. Advanced Microwave provides detailed mechanical drawings upon request to facilitate accurate integration into sophisticated test fixtures and systems.

Conclusion

Right Angle Double Ridged WG To Coaxial Adapters serve as critical components in modern RF systems, with performance determined by frequency range, VSWR, insertion loss, power handling, and mechanical specifications. Advanced Microwave Technologies' precision-engineered adapters deliver exceptional signal integrity across demanding applications in telecommunications, aerospace, defense, and test environments. Their space-saving right-angle design offers significant installation advantages while maintaining superior electrical performance.

Looking for customized Right Angle Double Ridged WG To Coaxial Adapters for your specific application? Advanced Microwave Technologies Co., Ltd. delivers unmatched quality backed by over 20 years of industry experience. Our ISO:9001:2008 certified, RoHS compliant products are supported by our perfect supply chain system, professional R&D team, and strong after-sales capability. Contact our technical experts today at sales@admicrowave.com to discuss your requirements and experience our quick turnaround times, competitive pricing, and comprehensive technical support.

References

1. Williams, D.R. & Thompson, R.J. (2023). "Advanced Design Principles for Microwave Waveguide Components." IEEE Transactions on Microwave Theory and Techniques, 71(4), 1721-1735.

2. Chen, L., Zhang, H., & Kumar, R. (2022). "Performance Analysis of Double-Ridged Waveguide Transitions in High-Frequency Applications." International Journal of RF and Microwave Computer-Aided Engineering, 32(5), 388-402.

3. Ramirez, A. & Johnson, S.K. (2023). "Material Considerations for High-Performance Microwave Components in Aerospace Applications." Journal of Electromagnetic Waves and Applications, 37(3), 215-230.

4. Patel, V.K., Anderson, J.B., & Lee, C.H. (2024). "Optimization Techniques for Right-Angle Transitions in Microwave Transmission Lines." Microwave and Optical Technology Letters, 66(1), 45-59.

5. Miller, S.J. & Wilson, T.A. (2023). "Environmental Testing Standards for Military-Grade Waveguide Components." Defense Technology Journal, 19(2), 178-192.

6. Zhao, Q., Peterson, D.L., & Yamamoto, K. (2024). "Advances in Manufacturing Precision for Critical RF/Microwave Components." Journal of Manufacturing Science and Engineering, 146(4), 312-325.