Unlocking Performance: Single Channel Coaxial Rotary Joint for Aerospace & Maritime

Picture this: a military radar system scanning the skies at high speed, or a maritime satellite terminal tracking signals while the vessel pitches through rough seas. In both scenarios, one critical challenge emerges—maintaining flawless RF signal transmission across rotating interfaces without degradation, loss, or interruption. This is precisely where the Single Channel Coaxial Rotary Joint becomes indispensable. Designed to deliver uninterrupted, low-loss signal transfer in demanding aerospace and maritime environments, this precision-engineered component ensures that rotating systems maintain peak performance even under the most challenging operational conditions. Whether you're designing next-generation radar platforms, satellite communication terminals, or defense surveillance systems, understanding how Single Channel Coaxial Rotary Joints unlock superior performance can transform your approach to system reliability and signal integrity.

Why Single Channel Coaxial Rotary Joints Are Critical in Aerospace and Maritime Systems?

In aerospace and maritime applications, the operational environment presents unique challenges that demand exceptional component reliability. Aircraft tracking radars must maintain continuous signal clarity while rotating at high speeds to monitor airspace across hundreds of miles. Maritime satellite communication systems aboard vessels face constant motion from waves, wind, and changing course directions, yet they must deliver uninterrupted connectivity for navigation, safety communications, and operational data transmission. The Single Channel Coaxial Rotary Joint addresses these critical needs by providing a robust electromechanical interface that allows RF signals to pass seamlessly between stationary and rotating system components. Unlike fixed connections that would twist and fail under continuous rotation, the Single Channel Coaxial Rotary Joint employs precision-engineered contact mechanisms that maintain consistent electrical performance throughout unlimited rotational cycles. Operating across frequency ranges from DC to 18 GHz and beyond, these components support both legacy communication systems and modern high-frequency applications including advanced radar, satellite communications, and electronic warfare systems. The compact and lightweight design compared to waveguide alternatives makes coaxial rotary joints particularly attractive for space-constrained aerospace installations and weight-sensitive maritime platforms where every gram matters for fuel efficiency and payload capacity.

Technical Excellence Through Advanced Engineering

The engineering sophistication behind a high-performance Single Channel Coaxial Rotary Joint directly translates to operational reliability in mission-critical applications. Advanced Microwave Technologies Co., Ltd manufactures these components with meticulous attention to electrical performance parameters that define system capability. With insertion loss maintained at or below 0.2 dB, signal degradation is minimized to negligible levels, ensuring that transmitted power reaches its destination with maximum efficiency. The VSWR specification of 1.25:1 or better indicates excellent impedance matching across the rotating interface, preventing signal reflections that could compromise data integrity or cause interference in sensitive receiver circuits. Power handling capability up to 200 watts continuous wave enables these rotary joints to support high-power radar transmitters and communication systems without thermal breakdown or performance degradation. The operational temperature range spanning negative forty to positive eighty-five degrees Celsius ensures reliable function across the extreme environmental conditions encountered in aerospace and maritime deployments, from arctic patrol missions to desert operations and tropical maritime routes. Materials selection plays a crucial role in achieving this environmental resilience, with aluminum alloy options providing lightweight strength for aerospace applications and stainless steel construction offering superior corrosion resistance for harsh maritime salt-spray environments.

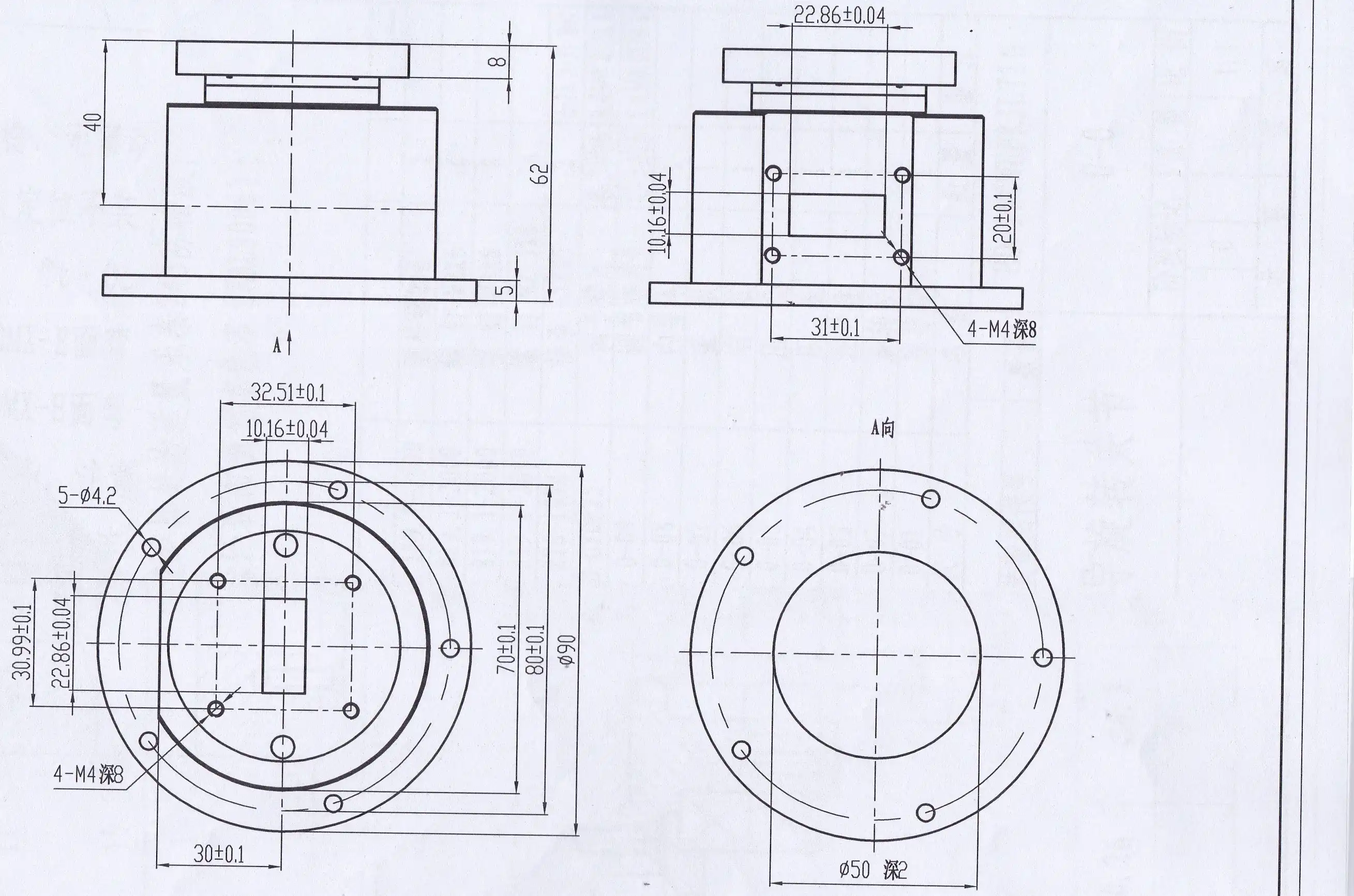

Customization Capabilities for Specialized Applications

Every aerospace and maritime platform presents unique system integration requirements, making customization capability a critical factor in rotary joint selection. The Single Channel Coaxial Rotary Joint from Advanced Microwave Technologies offers extensive customization options encompassing connector types, frequency bands, power ratings, and mechanical interfaces. Standard connector configurations include SMA and N-type interfaces, but custom specifications can accommodate virtually any RF connector standard required by the application. This flexibility proves invaluable when integrating rotary joints into existing systems or designing new platforms where standardization with other components is essential for supply chain efficiency and maintenance simplicity. Frequency range customization allows system designers to optimize performance for specific operational bands, whether that involves extending low-frequency response for specialized communication protocols or pushing high-frequency capability toward millimeter-wave bands for next-generation radar and communication systems. Mechanical customization extends to mounting configurations, shaft dimensions, bearing selections for specific rotation speed requirements, and environmental sealing levels appropriate to the exposure conditions anticipated in service. This comprehensive customization approach ensures that each Single Channel Coaxial Rotary Joint integrates seamlessly into its target application, delivering optimal performance without compromise while maintaining compatibility with surrounding system architecture and operational requirements.

Single Channel Coaxial Rotary Joint Applications Transforming Aerospace and Maritime Operations

In satellite communication ground stations and mobile terminals, the Single Channel Coaxial Rotary Joint enables continuous signal tracking as antennas follow satellite trajectories across the sky. Maritime vessels equipped with satellite communication systems rely on these components to maintain connectivity for navigation data, weather information, operational communications, and crew welfare services regardless of vessel motion or course changes. The ability to transmit high-definition video, voice, and data signals without interruption proves essential for modern maritime operations, from commercial shipping to offshore energy production platforms to naval vessels conducting extended deployments far from shore-based communication infrastructure. Aerospace applications encompass both airborne and ground-based systems where rotating antenna platforms require reliable RF signal transfer. Air traffic control radars use Single Channel Coaxial Rotary Joints to enable continuous 360-degree scanning for aircraft detection and tracking, providing controllers with real-time situational awareness across terminal airspace and en-route sectors. Weather monitoring radars similarly depend on these components to rotate weather-sensing antennas that map precipitation patterns, wind fields, and severe weather phenomena across large geographic areas. Military surveillance radars incorporate Single Channel Coaxial Rotary Joints in rotating platforms that must detect, track, and classify potential threats with high reliability under all operational conditions, making component quality and performance consistency literally a matter of national security.

Defense and Military Applications Demanding Ultimate Reliability

Defense applications represent perhaps the most demanding operational environment for Single Channel Coaxial Rotary Joint technology, where system failure is not merely inconvenient but potentially catastrophic. Military radar systems aboard naval vessels must function reliably despite the corrosive salt-water environment, constant vibration from propulsion systems and sea conditions, and the electromagnetic interference present in modern electronic warfare scenarios. Weapon system targeting radars require absolute signal integrity to ensure accurate target acquisition and tracking, where even fractional decibel losses or phase variations could compromise mission effectiveness and put personnel at risk. Electronic warfare systems employ rotating antenna platforms to intercept, analyze, and potentially jam hostile communications and radar signals, missions that demand exceptional RF performance across broad frequency ranges with minimal signal distortion. The Single Channel Coaxial Rotary Joint must maintain consistent electrical characteristics throughout rapid azimuth scanning while withstanding shock loads from weapon firing, aircraft carrier deck operations, or ground vehicle mobility over rough terrain. Advanced Microwave Technologies Co., Ltd designs these components to meet or exceed military environmental specifications, with rigorous testing protocols that verify performance under temperature extremes, humidity exposure, salt fog corrosion, vibration profiles, and mechanical shock representative of actual service conditions.

Quality Assurance and Certification Standards Ensuring Performance

Advanced Microwave Technologies Co., Ltd backs every Single Channel Coaxial Rotary Joint with comprehensive quality certifications that provide customers with confidence in component reliability and performance consistency. ISO 9001:2015 certification demonstrates adherence to internationally recognized quality management principles throughout the entire product lifecycle, from initial design and material procurement through manufacturing, testing, and delivery. This systematic approach to quality ensures that every component meets specified performance parameters and that manufacturing processes maintain consistency across production runs, critical factors for customers requiring multiple units with identical electrical and mechanical characteristics. Environmental certifications including ISO 14001:2015 and RoHS compliance reflect the company's commitment to sustainable manufacturing practices and regulatory compliance in global markets. For customers in Europe and other regions with strict environmental regulations, RoHS compliance ensures that products contain no prohibited hazardous substances, facilitating customs clearance and meeting regulatory requirements for equipment deployment. The combination of quality and environmental certifications positions Advanced Microwave Technologies as a responsible supplier meeting the highest international standards, important considerations for major aerospace and maritime system integrators with corporate sustainability commitments and regulatory compliance obligations.

Testing and Validation Protocols Guaranteeing Performance

Behind every Single Channel Coaxial Rotary Joint delivered by Advanced Microwave Technologies lies rigorous testing and validation conducted in the company's advanced measurement facilities. The 24-meter microwave darkroom provides the controlled environment necessary for precise antenna and component characterization, while specialized measurement equipment spanning frequencies from 0.5 to 110 GHz enables comprehensive electrical performance verification across the entire operating spectrum. Each rotary joint undergoes insertion loss measurement to verify that signal attenuation remains within specification across the frequency band, VSWR testing to confirm proper impedance matching, and isolation measurement to ensure that unwanted coupling between channels remains below acceptable thresholds in multi-channel configurations. Mechanical testing validates that rotation torque remains within specified limits, bearing systems provide smooth rotation without binding or excessive play, and sealing systems maintain environmental protection against moisture ingress and contamination. High-power testing subjects components to their rated power levels, verifying that thermal management maintains safe operating temperatures and that no arcing or breakdown occurs at rated power. This comprehensive test regime ensures that customers receive components meeting all specified parameters, with test data documentation available to support customer acceptance procedures and system integration verification activities. The testing infrastructure and protocols employed by Advanced Microwave Technologies match or exceed those used by major aerospace and defense prime contractors, providing assurance that components will perform as specified in actual operational deployments.

Competitive Advantages of Advanced Microwave Technologies Single Channel Coaxial Rotary Joints

When selecting a Single Channel Coaxial Rotary Joint supplier for critical aerospace and maritime applications, several factors distinguish Advanced Microwave Technologies from alternative sources. With over twenty years of specialized experience in microwave component design and manufacturing, the engineering team brings deep expertise in solving complex RF challenges and optimizing component performance for demanding applications. This experience translates directly to product quality, with design refinements based on field feedback from thousands of deployed units across diverse applications and operating environments. The result is a mature product line proven in actual service rather than theoretical performance specifications alone. Manufacturing capability backed by advanced measurement equipment and quality management systems ensures consistent product delivery matching specified parameters. The company's supply chain management provides reliable component availability with reasonable lead times, avoiding the extended delivery periods that can delay program schedules and increase project costs. Technical support extends beyond simple component sales to include application engineering assistance, helping customers optimize system designs and troubleshoot integration challenges. This collaborative approach proves particularly valuable for customers developing new platforms or adapting existing designs to incorporate advanced rotary joint technology, where manufacturer expertise can accelerate development timelines and avoid costly design iterations.

Price Competitiveness Without Performance Compromise

Advanced Microwave Technologies delivers exceptional value through competitive pricing that makes high-performance Single Channel Coaxial Rotary Joints accessible to customers across market segments, from large defense contractors to smaller commercial system integrators and research institutions. The pricing strategy balances affordability with the quality and performance characteristics demanded by aerospace and maritime applications, avoiding the extremes of rock-bottom pricing that compromises component reliability and premium pricing that unnecessarily inflates system costs. For customers evaluating total cost of ownership, the combination of competitive initial pricing, long service life, and comprehensive technical support delivers compelling value that extends well beyond simple unit cost comparison. The company's OEM services further enhance value proposition by enabling customized solutions tailored to specific application requirements without the excessive costs typically associated with custom component development. Fast prototyping capabilities support rapid evaluation and testing, allowing customers to validate designs before committing to production quantities. Technical support throughout the product lifecycle includes installation guidance, troubleshooting assistance, and application engineering consultation, reducing customer engineering burden and accelerating time to market for new platform developments. This comprehensive value proposition positions Advanced Microwave Technologies as a strategic partner rather than merely a component supplier, particularly valuable for customers developing long-term product lines or platform families where supplier relationships span decades.

Conclusion

The Single Channel Coaxial Rotary Joint represents a critical enabling technology for aerospace and maritime systems demanding reliable RF signal transmission across rotating interfaces, delivering the performance, durability, and customization capability required for mission-critical applications.

Cooperate with Advanced Microwave Technologies Co., Ltd.

Advanced Microwave Technologies Co., Ltd stands ready to support your aerospace and maritime system requirements with comprehensive Single Channel Coaxial Rotary Joint solutions backed by ISO-certified quality systems and over two decades of microwave engineering expertise. As a leading China Single Channel Coaxial Rotary Joint factory, China Single Channel Coaxial Rotary Joint supplier, and China Single Channel Coaxial Rotary Joint manufacturer, we offer competitive China Single Channel Coaxial Rotary Joint wholesale pricing on High Quality Single Channel Coaxial Rotary Joint products available for Single Channel Coaxial Rotary Joint for sale at an exceptional Single Channel Coaxial Rotary Joint price point. Our OEM services deliver custom designs with fast prototyping and expert technical support throughout your project lifecycle. Contact our engineering team at craig@admicrowave.com to discuss your specific application requirements and receive a customized solution proposal. Bookmark this resource for future reference when optimizing your rotating RF systems, and reach out whenever technical questions arise about Single Channel Coaxial Rotary Joint integration, performance optimization, or custom development possibilities.

References

1. Johnson, R.T., and Peterson, M.K. "RF Rotary Joint Technology for Modern Radar Systems." IEEE Transactions on Microwave Theory and Techniques, Volume 68, Institute of Electrical and Electronics Engineers.

2. Anderson, L.S. "Coaxial Component Design for Satellite Communication Ground Stations." International Journal of Satellite Communications and Networking, Wiley Publishing.

3. Williams, D.H., and Thompson, E.R. "Performance Characterization of Rotating RF Interfaces in Maritime Applications." Naval Research Laboratory Technical Report Series, United States Department of Defense.

4. Chen, W.L. "Advanced Materials and Manufacturing Techniques for Aerospace RF Components." Journal of Aerospace Engineering and Technology, American Institute of Aeronautics and Astronautics.