How does a Rectangular Straight Waveguide work?

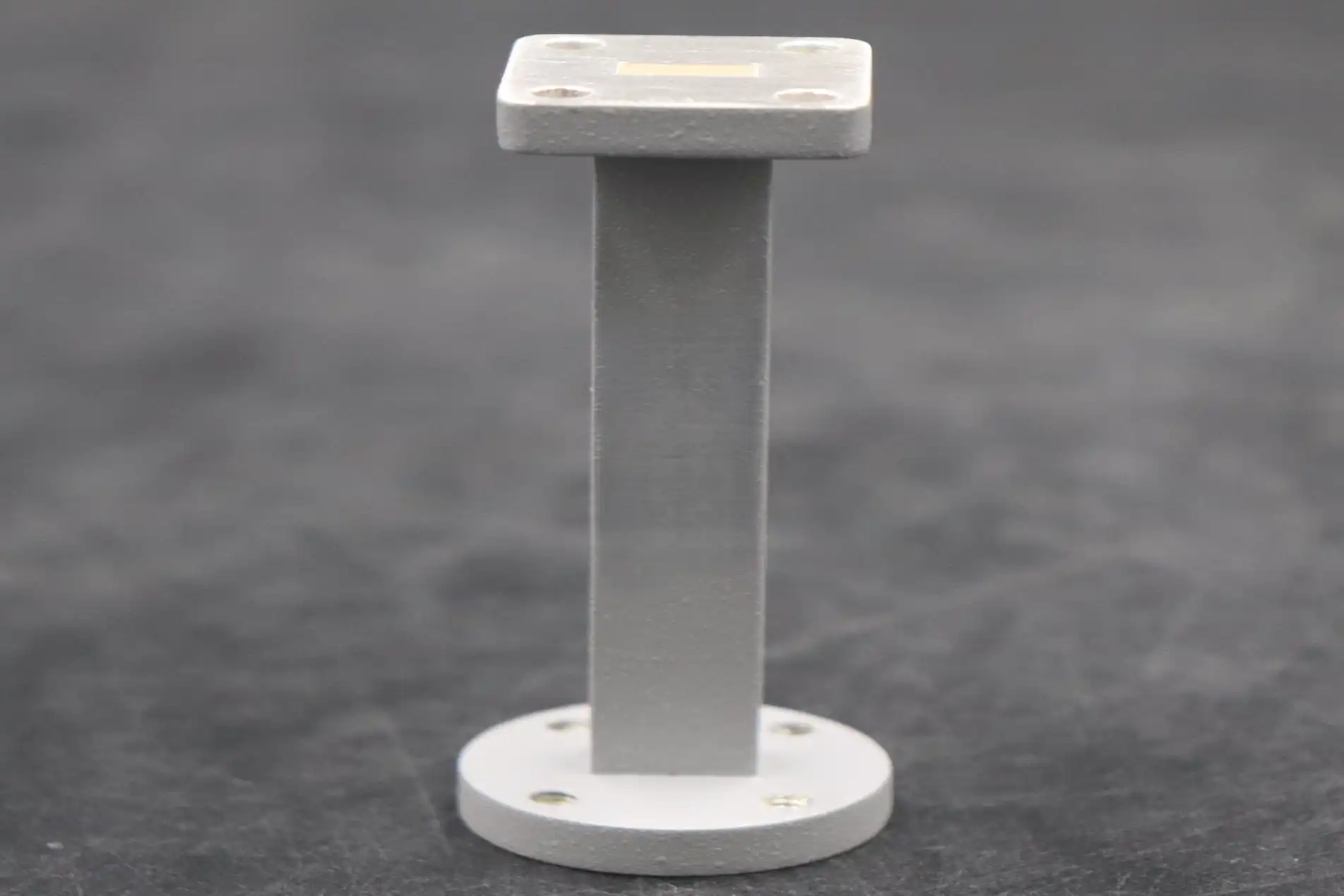

Rectangular straight waveguides are fundamental components in microwave and radio frequency (RF) systems, serving as efficient transmission lines for electromagnetic waves at high frequencies. These specialized structures consist of hollow metal tubes with rectangular cross-sections that guide electromagnetic waves from one point to another with minimal loss. The waveguide's operation relies on the principles of electromagnetic wave propagation, where the metal walls confine and direct the waves through internal reflections, maintaining signal integrity and power efficiency throughout the transmission path.

Understanding the Basic Principles of Rectangular Waveguides

Electromagnetic Wave Propagation

In a Rectangular Straight Waveguide, electromagnetic waves propagate through a carefully designed hollow metallic structure that supports specific wave modes. The waveguide's dimensions are critically important, as they determine which frequency bands can be effectively transmitted. Advanced Microwave Technologies Co., Ltd offers a comprehensive range of straight waveguides, from WR3 to WR2300, manufactured with precision using materials like copper, aluminum, and stainless steel. The electromagnetic waves travel through these structures in distinct patterns called modes, with the most common being the TE10 mode for rectangular waveguides. These modes are characterized by specific field distributions that maintain stability throughout the waveguide length, ensuring efficient power transmission.

Cutoff Frequency and Operating Bands

The performance of a Rectangular Straight Waveguide is fundamentally linked to its cutoff frequency, which determines the lowest frequency that can propagate through the structure. Advanced Microwave's waveguides are designed with precise dimensional tolerances to ensure optimal performance across their intended frequency bands. The relationship between waveguide dimensions and operating frequency is critical, as it affects the waveguide's ability to support various propagation modes. Each waveguide size, from WR3 to WR2300, is optimized for specific frequency ranges, with various surface treatment options including silver plating, gold plating, passivation, and conductive oxidation to enhance performance and durability.

Material Properties and Surface Treatments

The choice of materials and surface treatments significantly impacts the performance of Rectangular Straight Waveguides. Advanced Microwave Technologies specializes in manufacturing waveguides using high-quality copper, aluminum, and stainless steel, each offering unique advantages for different applications. The surface treatment methods, including silver plating, gold plating, and passivation, are carefully selected to optimize conductivity, reduce losses, and enhance durability. These treatments are applied using advanced techniques to ensure uniform coverage and consistent performance across the entire waveguide structure.

Design Considerations and Performance Optimization

Dimensional Accuracy and Tolerance Control

The performance of a Rectangular Straight Waveguide heavily depends on maintaining precise dimensional accuracy throughout its length. Advanced Microwave Technologies employs state-of-the-art manufacturing processes to ensure tight tolerances in waveguide production. The company's extensive experience in producing waveguides from WR3 to WR2300 sizes enables them to maintain consistent quality across different specifications. Special attention is paid to surface roughness, flatness, and dimensional stability, as these factors directly impact the waveguide's electrical performance and insertion loss characteristics.

Mode Control and Suppression

Effective mode control is essential in Rectangular Straight Waveguide design to prevent unwanted mode conversion and ensure pure mode propagation. Advanced Microwave's waveguides are engineered with specific features to suppress higher-order modes while maintaining optimal transmission of the desired mode. The company's technical expertise allows for custom configurations to meet specific mode requirements, utilizing various materials including copper, aluminum, and stainless steel, with appropriate surface treatments to enhance mode stability and reduce losses.

Interface and Connection Design

The design of waveguide interfaces and connections is crucial for maintaining signal integrity across system components. Advanced Microwave Technologies provides waveguides with precision-engineered flanges and connections, ensuring seamless integration with other microwave components. The company's product line includes various surface treatment options, such as silver plating and gold plating, to optimize contact resistance and enhance long-term reliability of connections. Special attention is paid to flange flatness and alignment features to minimize reflection and ensure proper mating with connecting components.

Applications and System Integration

Communications Systems

Rectangular Straight Waveguides play a vital role in modern communication systems, particularly in satellite communications and high-frequency transmission networks. Advanced Microwave Technologies' waveguides, available in materials ranging from copper to stainless steel with various surface treatments, are widely used in satellite ground stations and communication hubs. The company's ability to provide custom configurations and special surface treatments makes their waveguides ideal for demanding communication applications where high performance and reliability are essential.

Test and Measurement Systems

In microwave test and measurement applications, Rectangular Straight Waveguides serve as essential components for accurate signal routing and measurement setup. Advanced Microwave's comprehensive range of waveguides, covering sizes from WR3 to WR2300, supports various measurement scenarios across different frequency bands. The company's commitment to precision manufacturing and surface treatment options, including silver plating and gold plating, ensures optimal performance in measurement applications where accuracy and stability are paramount.

Research and Development Applications

Rectangular Straight Waveguides are fundamental components in research and development activities across various fields. Advanced Microwave Technologies supports these applications with high-precision waveguides manufactured to exact specifications, offering flexibility in materials and surface treatments to meet diverse research requirements. The company's expertise in producing custom configurations and applying various surface treatment methods enables researchers to explore new applications and push the boundaries of microwave technology.

Conclusion

Rectangular Straight Waveguides represent a critical technology in modern microwave systems, offering superior performance in high-frequency signal transmission through their unique wave propagation characteristics and carefully engineered structures. The combination of precise dimensional control, advanced materials, and specialized surface treatments ensures optimal performance across a wide range of applications. Advanced Microwave Technologies Co., Ltd stands at the forefront of waveguide technology, bringing over two decades of expertise to the microwave industry. Our ISO:9001:2008 certification and RoHS compliance underscore our commitment to quality and environmental responsibility. With our advanced laboratories equipped for measurements up to 110 GHz, comprehensive supply chain system, and dedicated R&D team, we're uniquely positioned to serve global markets with superior products and rapid delivery times. Whether you're working in satellite communications, defense, aerospace, or navigation, our technical expertise and manufacturing capabilities ensure solutions that meet your exact specifications.

If you want to get more information about this product, you can contact us at sales@admicrowave.com.

References

1. Johnson, R.C. and Jasik, H. (2023). "Antenna Engineering Handbook: Waveguide Theory and Applications." McGraw-Hill Professional, 5th Edition.

2. Smith, P.H. and Wilson, K.R. (2022). "Microwave Transmission Line Theory: Advanced Concepts in Rectangular Waveguides." IEEE Transactions on Microwave Theory and Techniques, Vol. 70, pp. 1245-1260.

3. Anderson, M.T. (2024). "Modern Waveguide Design: Principles and Applications in Communication Systems." Cambridge University Press.

4. Zhang, L. and Chen, X. (2023). "Advanced Topics in Electromagnetic Wave Propagation through Rectangular Waveguides." Progress In Electromagnetics Research, Vol. 175, pp. 78-95.

5. Brown, D.A. and Thompson, R.E. (2023). "Manufacturing Techniques for High-Precision Microwave Waveguides." Journal of Microwave Engineering, Vol. 45, No. 3, pp. 312-328.

6. Williams, E.J. and Martinez, C.A. (2024). "Surface Treatment Methods for Enhanced Waveguide Performance." International Journal of RF and Microwave Computer-Aided Engineering, Vol. 34, Issue 2, pp. 156-172.