How do fixed vs. variable waveguide attenuators differ in design, application, and attenuation range?

Understanding the distinctions between fixed and variable waveguide attenuators is crucial for engineers and system designers working with high-frequency microwave applications. These essential components serve different purposes in signal management, each offering unique advantages depending on the specific requirements of your system. Fixed waveguide attenuators provide consistent, predetermined attenuation levels with exceptional stability and reliability, while variable waveguide attenuators offer adjustable attenuation control for dynamic signal management. The choice between these two types significantly impacts system performance, cost-effectiveness, and operational flexibility across various applications including satellite communications, radar systems, and advanced microwave testing environments.

Design Architecture and Construction Differences

Structural Design Elements

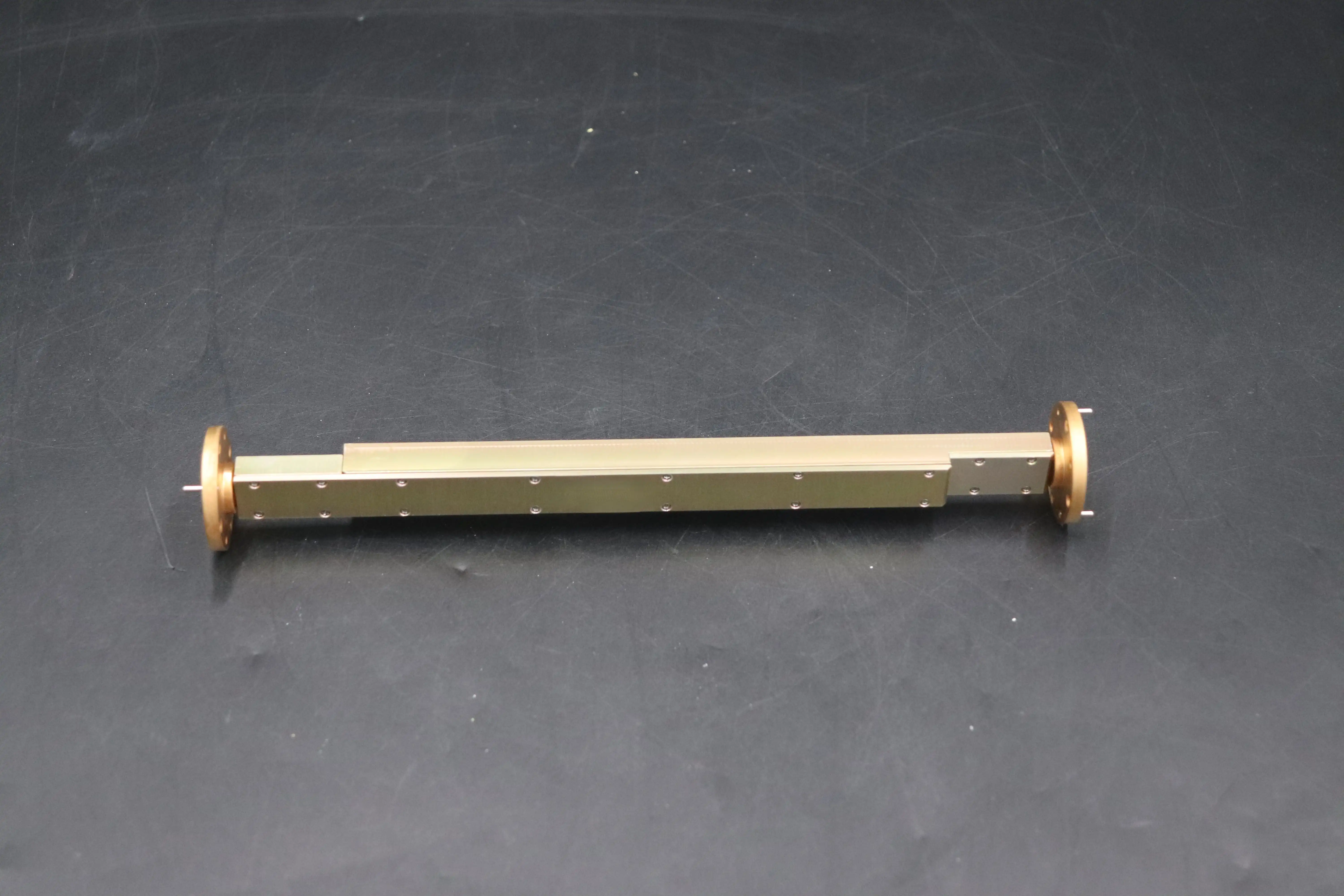

Fixed waveguide attenuators feature a simplified yet robust construction that prioritizes stability and reliability over adjustability. The waveguide attenuator design incorporates precision-engineered resistive elements permanently positioned within the waveguide structure, creating consistent attenuation values without any moving parts or adjustable components. This construction methodology ensures exceptional long-term stability and minimal maintenance requirements, making them ideal for applications where consistent performance is paramount. The resistive elements are typically fabricated using high-quality materials such as tantalum nitride or nichrome, carefully positioned and secured within the waveguide housing to maintain precise electrical characteristics throughout the device's operational lifetime. Advanced Microwave Technologies offers rectangular waveguide attenuators with typical attenuation values of 3dB, 6dB, 10dB, 20dB, and 30dB, featuring assembled construction with precision elements for optimum electrical performance.

Variable Attenuator Mechanisms

Variable waveguide attenuators employ sophisticated mechanical adjustment systems that allow real-time modification of attenuation levels during operation. These waveguide attenuator designs incorporate adjustable resistive elements, movable vanes, or rotating absorptive materials that can be precisely positioned to achieve desired attenuation values. The adjustment mechanisms range from simple manual controls to sophisticated motorized systems with remote operation capabilities. The complexity of variable attenuator construction requires careful engineering to maintain consistent performance across the entire adjustment range while ensuring mechanical stability and electrical repeatability. These systems often incorporate precision gear mechanisms, linear actuators, or stepper motor controls to provide accurate and repeatable attenuation adjustments, making them essential for applications requiring dynamic signal level control.

Material and Manufacturing Considerations

Both fixed and variable waveguide attenuators require careful material selection and precision manufacturing processes to ensure optimal performance characteristics. The waveguide attenuator construction utilizes high-grade aluminum, brass, or specialized alloys for the housing components, while the resistive elements employ materials specifically chosen for their electrical properties and thermal stability. Manufacturing tolerances must be maintained to extremely tight specifications to ensure consistent electrical performance and proper impedance matching. Advanced manufacturing techniques including precision machining, electroplating, and specialized joining methods are employed to create waveguide attenuators that meet stringent performance requirements. Quality control processes ensure that each unit meets specified electrical characteristics and mechanical tolerances before shipment to customers.

Application Scenarios and Use Cases

Fixed Attenuator Applications

Fixed waveguide attenuators excel in applications where consistent, predetermined attenuation levels are required throughout the system's operational lifetime. These waveguide attenuator units are particularly valuable in satellite communication systems where uplink and downlink signal levels must be maintained within specific parameters to ensure reliable data transmission. The stability and reliability of fixed attenuators make them ideal for use in reference standards, calibration systems, and measurement equipment where consistent attenuation values are essential for accurate measurements. In radar systems, fixed waveguide attenuators provide precise signal level control for transmitter protection, receiver sensitivity adjustment, and inter-stage isolation. Their robust construction and minimal maintenance requirements make them well-suited for remote installations, harsh environmental conditions, and applications where system reliability is critical. Advanced Microwave Technologies' fixed attenuators are perfect for satellite communications, aerospace and defense applications, and advanced microwave testing environments.

Variable Attenuator Applications

Variable waveguide attenuators serve applications requiring dynamic signal level adjustment and real-time system optimization. These waveguide attenuator systems are essential in automated test equipment where signal levels must be adjusted programmatically to perform comprehensive testing across multiple power levels and frequency ranges. In research and development laboratories, variable attenuators enable engineers to optimize system performance by adjusting signal levels during testing and evaluation phases. Communication systems benefit from variable waveguide attenuators in applications such as automatic gain control, signal conditioning, and adaptive power management. The ability to adjust attenuation levels in real-time makes these devices valuable for system commissioning, maintenance procedures, and troubleshooting activities where signal levels must be modified to isolate problems or verify system performance.

Industry-Specific Requirements

Different industries have specific requirements that influence the choice between fixed and variable waveguide attenuators. Aerospace and defense applications often require fixed waveguide attenuator solutions due to their reliability, stability, and resistance to environmental extremes. The precision engineering and minimal signal distortion characteristics make them essential for advanced weapon systems, navigation equipment, and secure communication systems. Telecommunications infrastructure benefits from both types, with fixed attenuators used for permanent installations and variable units employed for testing and maintenance activities. Research institutions and OEM manufacturers require customizable solutions that can be tailored to specific frequency ranges, power levels, and mechanical configurations to meet unique application requirements.

Attenuation Range and Performance Characteristics

Fixed Attenuator Performance Specifications

Fixed waveguide attenuators typically offer discrete attenuation values ranging from 1dB to 60dB or higher, depending on the specific application requirements and frequency range. These waveguide attenuator units provide exceptional accuracy and stability across their specified frequency ranges, with typical tolerances of ±0.5dB or better for precision applications. The fixed nature of these devices allows for optimization of electrical characteristics at specific attenuation levels, resulting in superior VSWR performance, minimal insertion loss variation, and excellent return loss characteristics. Advanced Microwave Technologies' fixed attenuators support frequencies up to 110 GHz with broad frequency coverage, making them suitable for high-frequency applications requiring precise signal control. The robust construction ensures long-term stability with minimal drift over temperature and time, providing reliable performance in challenging operating environments.

Variable Attenuator Range and Resolution

Variable waveguide attenuators offer continuous attenuation adjustment over specified ranges, typically from 0dB to 60dB or more, with resolution capabilities ranging from 0.1dB to 1dB depending on the adjustment mechanism employed. These waveguide attenuator systems provide flexibility for applications requiring precise signal level control across varying operating conditions. The adjustment range and resolution characteristics are carefully engineered to balance performance requirements with mechanical complexity and cost considerations. Modern variable attenuators incorporate digital control interfaces that enable remote operation and integration with automated test systems, providing precise control and excellent repeatability. The continuous adjustment capability allows for fine-tuning of system performance and optimization of signal-to-noise ratios in sensitive applications.

Frequency Response and Bandwidth Considerations

Both fixed and variable waveguide attenuators must maintain consistent performance characteristics across their specified frequency ranges while minimizing frequency-dependent variations in attenuation, VSWR, and phase response. The waveguide attenuator design optimization for specific frequency bands ensures optimal performance within the intended operating range. Fixed attenuators typically offer superior frequency response characteristics due to their optimized construction for specific attenuation levels, while variable attenuators must maintain acceptable performance across the entire adjustment range. Advanced design techniques and careful material selection enable both types to achieve excellent broadband performance suitable for modern communication and radar systems. The frequency response characteristics directly impact system performance and must be carefully considered during system design and component selection processes.

Conclusion

The choice between fixed and variable waveguide attenuators depends on specific application requirements, with fixed units offering superior stability and reliability for permanent installations, while variable attenuators provide essential flexibility for testing and dynamic signal management. Both types play crucial roles in modern microwave systems, contributing to improved signal control, reduced noise, and enhanced overall system performance across diverse applications.

At Advanced Microwave Technologies Co., Ltd., we leverage over 20 years of microwave expertise and ISO:9001:2008 certification to deliver exceptional waveguide attenuator solutions. Our comprehensive product portfolio, supported by advanced measurement equipment up to 110 GHz and strict quality control processes, ensures that every component meets the highest standards for satellite communications, defense, aerospace, and navigation applications. Whether you need standard fixed attenuators or customized variable solutions, our experienced technical team provides comprehensive support from initial design through final installation.

Ready to optimize your microwave system performance with precision-engineered waveguide attenuators? Our expert engineers are standing by to help you select the perfect solution for your specific requirements. From rapid prototyping to full-scale production, we offer complete OEM services with quick turnaround times and competitive pricing advantages. Contact us today at mia@admicrowave.com to discuss your project requirements and discover how our advanced waveguide technologies can enhance your system performance and reliability.

References

1. Montgomery, C. G., Dicke, R. H., & Purcell, E. M. (2021). Principles of Microwave Circuits. Institution of Engineering and Technology Press.

2. Pozar, D. M. (2022). Microwave Engineering: Fourth Edition. John Wiley & Sons.

3. Collin, R. E. (2020). Foundations for Microwave Engineering: Second Edition. IEEE Press.

4. Ragan, G. L. (2019). Microwave Transmission Circuits: MIT Radiation Laboratory Series. Artech House Publishers.

5. Matthaei, G., Young, L., & Jones, E. M. T. (2023). Microwave Filters, Impedance-Matching Networks, and Coupling Structures. Norwood Publications.

6. Harvey, A. F. (2021). Microwave Engineering Principles and Applications. Academic Press.