Growing Demand for Conical Horn Lens Antennas in Satellite Testing

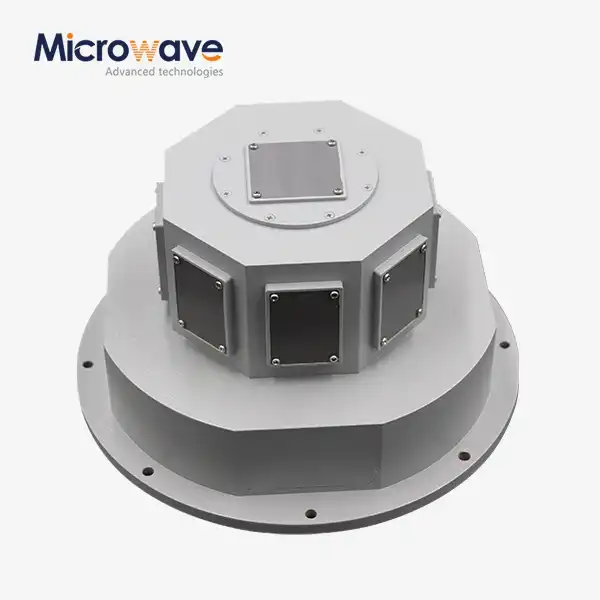

The satellite testing industry is experiencing unprecedented growth, driving significant demand for advanced antenna technologies that can deliver precise, reliable performance across diverse frequency ranges. At the forefront of this technological evolution, the Conical Horn Lens Antenna has emerged as a critical component for modern satellite testing applications. These sophisticated devices combine the benefits of conical horn structures with plano-convex lens elements, creating compact solutions that offer exceptional signal quality and reduced sidelobe levels compared to conventional horn antennas. As satellite systems become increasingly complex and operate across broader frequency spectrums, the need for high-performance testing equipment has intensified, positioning Conical Horn Lens Antennas as indispensable tools for ensuring satellite system reliability and performance validation.

Technical Advantages Driving Market Adoption

Enhanced Signal Quality and Precision

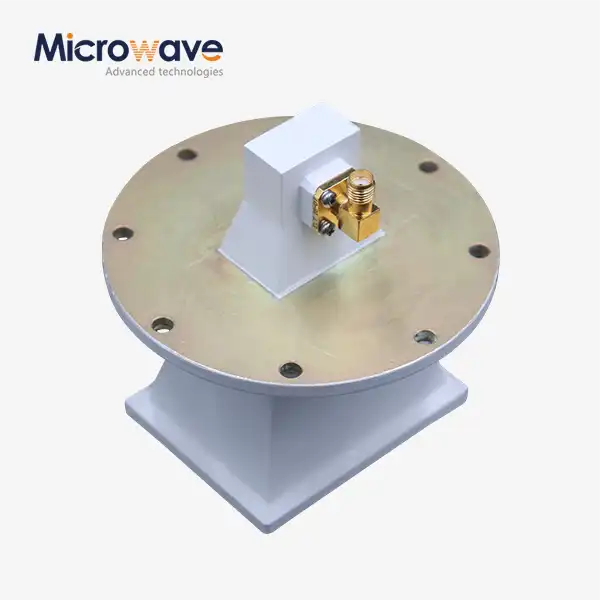

The superior performance characteristics of Conical Horn Lens Antennas have made them increasingly popular in satellite testing environments where precision is paramount. These antennas demonstrate exceptional capability in maintaining signal integrity across extended frequency ranges, particularly in the 0.5-110GHz spectrum that covers both legacy and next-generation satellite communication systems. The Conical Horn Lens Antenna design incorporates advanced engineering principles that minimize signal distortion and maximize gain efficiency, achieving up to 45 dB gain performance that surpasses traditional antenna configurations. The integration of plano-convex lens elements with conical horn structures creates a unique electromagnetic environment that focuses energy more effectively while reducing unwanted sidelobe radiation. This combination results in cleaner signal patterns that are essential for accurate satellite testing procedures, enabling engineers to obtain more reliable measurement data and validate system performance with greater confidence. The low VSWR characteristics inherent in these designs further enhance their appeal, as reduced signal reflection translates directly to improved measurement accuracy and system efficiency during critical testing phases.

Compact Design and Operational Efficiency

Modern satellite testing facilities face increasing space constraints while simultaneously requiring enhanced measurement capabilities, making the compact nature of Conical Horn Lens Antennas particularly valuable. Unlike traditional horn antennas that require extensive axial dimensions to achieve comparable performance levels, the Conical Horn Lens Antenna leverages its lens element to achieve equivalent or superior performance in significantly reduced physical footprints. This space efficiency allows testing facilities to accommodate more comprehensive measurement setups within existing infrastructure, maximizing operational efficiency and enabling more thorough satellite system validation processes. The lightweight construction of these antennas facilitates easier installation and reconfiguration, reducing setup times and operational costs associated with complex testing procedures. Advanced manufacturing techniques ensure that despite their compact dimensions, these antennas maintain exceptional durability and long-term reliability, making them suitable for continuous operation in demanding testing environments. The reduced size also translates to lower shipping costs and simplified logistics for organizations operating multiple testing facilities or requiring portable testing solutions for field applications.

Versatile Polarization and Frequency Capabilities

Satellite testing applications increasingly require antenna systems capable of handling diverse polarization schemes and broad frequency ranges, areas where Conical Horn Lens Antennas excel through their inherent design flexibility. The basic Conical Horn Lens Antenna configuration operates effectively in linear polarization modes, providing excellent performance for standard satellite communication testing protocols. However, the addition of specialized components such as VTCWP 90° type circular waveguide polarization phase shifters enables seamless transition to circular polarization operation, expanding the antenna's utility across a broader range of satellite system architectures. This adaptability proves particularly valuable in modern satellite testing scenarios where systems may employ different polarization schemes for various operational modes or frequency bands. The wide frequency support capabilities ensure compatibility with both established satellite communication protocols and emerging technologies, including 5G and future 6G systems that operate at higher frequency ranges. Customizable options allow testing facilities to tailor antenna specifications to match specific satellite system requirements, ensuring optimal measurement accuracy and comprehensive system validation across diverse operational parameters.

Industry Applications and Market Growth

Telecommunications and Satellite Communications Sector

The telecommunications industry's rapid expansion, particularly in satellite-based communication services, has created substantial demand for high-quality testing equipment including Conical Horn Lens Antennas. Modern satellite ground stations require comprehensive testing to ensure reliable signal reception and transmission capabilities, making these antennas essential components in validation processes. The Conical Horn Lens Antenna provides the precision necessary for testing complex satellite communication protocols, enabling operators to verify system performance across various operational conditions and frequency allocations. Advanced satellite constellation projects, including low Earth orbit networks designed to provide global broadband coverage, rely heavily on precise antenna testing to ensure seamless service delivery and optimal network performance. The ability to conduct accurate far-field measurements using these antennas allows engineers to validate antenna patterns, gain characteristics, and polarization purity essential for maintaining communication quality standards. Testing facilities equipped with state-of-the-art measurement chambers, such as the 24-meter microwave darkroom environments, utilize these antennas to simulate real-world operational conditions and verify satellite system performance under controlled laboratory conditions, ensuring reliable service delivery upon deployment.

Aerospace and Defense Applications

The aerospace and defense sectors represent significant growth areas for Conical Horn Lens Antenna applications, driven by increasing investments in advanced radar systems, missile guidance technologies, and surveillance equipment. Military and civilian radar systems require extensive testing to ensure reliable target detection and tracking capabilities across diverse operational environments, making high-performance test antennas crucial for system validation. The Conical Horn Lens Antenna design provides the precision and reliability necessary for testing sophisticated defense systems that operate across wide frequency ranges and demand exceptional performance standards. Advanced missile guidance systems rely on precise antenna performance for accurate navigation and target acquisition, requiring comprehensive testing protocols that validate system capabilities under various operational scenarios. The low transmission loss characteristics of these antennas make them particularly suitable for testing long-range communication and radar systems where signal integrity over extended distances is critical. Defense contractors increasingly specify these antennas for testing facilities due to their proven reliability and consistent performance characteristics, ensuring that critical defense systems meet stringent operational requirements before deployment in field environments.

Scientific Research and Development Initiatives

Research institutions and scientific organizations worldwide are driving significant demand for advanced antenna testing capabilities, particularly in emerging fields such as radio astronomy, atmospheric research, and experimental communication technologies. The Conical Horn Lens Antenna serves as an essential tool for researchers investigating electromagnetic phenomena, developing new communication protocols, and advancing our understanding of radio frequency propagation characteristics. Academic institutions conducting cutting-edge research in millimeter-wave technologies rely on these antennas for precise measurements and system characterization studies. The exceptional measurement accuracy achievable with these antennas enables researchers to gather high-quality data essential for advancing scientific knowledge and developing next-generation technologies. National research laboratories utilize these antennas in large-scale measurement facilities to support various research initiatives, from atmospheric monitoring systems to deep space communication studies. The customizable nature of these antennas allows researchers to adapt specifications to match specific experimental requirements, ensuring optimal measurement conditions for diverse research applications. This flexibility has made them increasingly popular in university research programs and government research facilities worldwide, contributing to the growing demand for high-performance antenna testing solutions.

Manufacturing Excellence and Quality Assurance

Advanced Production Capabilities and Standards

The manufacturing of high-quality Conical Horn Lens Antennas requires sophisticated production facilities and rigorous quality control processes to ensure consistent performance and reliability. Advanced Microwave Technologies Co., Ltd. operates state-of-the-art manufacturing facilities equipped with precision machining capabilities and advanced testing equipment necessary for producing these complex antenna systems. The Conical Horn Lens Antenna manufacturing process involves intricate fabrication procedures that demand exceptional precision in both mechanical construction and electromagnetic design optimization. ISO 9001:2015 certification ensures that all manufacturing processes adhere to international quality standards, providing customers with confidence in product reliability and performance consistency. Each antenna undergoes comprehensive testing procedures using advanced measurement equipment capable of operation up to 110 GHz, ensuring that performance specifications are met across the entire operational frequency range. Environmental management systems certified to ISO 14001:2015 standards ensure that manufacturing processes minimize environmental impact while maintaining high production quality. The integration of automated production techniques with skilled craftsmanship results in antennas that consistently meet or exceed customer specifications while maintaining competitive pricing and delivery schedules.

Customization and OEM Services

The diverse requirements of satellite testing applications necessitate flexible manufacturing approaches that can accommodate specific customer needs and unique application requirements. Advanced Microwave Technologies Co., Ltd. offers comprehensive OEM services that enable customers to obtain Conical Horn Lens Antenna solutions precisely tailored to their specific operational requirements. Custom design capabilities allow for modifications in frequency range, gain characteristics, polarization options, and physical dimensions to match particular testing protocols and facility constraints. Experienced engineering teams work closely with customers to develop optimal antenna solutions that maximize measurement accuracy while meeting budget and timeline requirements. Prototyping services enable customers to evaluate antenna performance before committing to full-scale production, reducing risks and ensuring optimal system integration. The flexible manufacturing approach accommodates orders ranging from single prototypes for research applications to large-scale production runs for commercial testing facilities. Technical support services provide ongoing assistance with installation guidance, system integration, and troubleshooting support, ensuring optimal antenna performance throughout the product lifecycle. This comprehensive approach to customer service has established strong relationships with clients across diverse industries, contributing to sustained demand growth and market expansion.

Quality Control and Performance Validation

Rigorous quality control procedures ensure that every Conical Horn Lens Antenna meets stringent performance standards before delivery to customers. Advanced testing facilities equipped with sophisticated measurement equipment enable comprehensive performance validation across all specified operational parameters. The Conical Horn Lens Antenna testing protocol includes gain measurement verification, VSWR characterization, radiation pattern analysis, and polarization purity assessment to ensure optimal performance in actual application environments. Controlled testing environments, including specialized microwave darkrooms with extended measurement distances, provide accurate far-field characterization that closely represents real-world operational conditions. Statistical quality control processes monitor production consistency and identify potential issues before they impact customer deliveries. Environmental stress testing ensures that antennas maintain performance specifications under various operational conditions, including temperature extremes, humidity variations, and mechanical stress. RoHS compliance certification confirms that all materials and manufacturing processes meet environmental safety standards, providing customers with assurance regarding regulatory compliance. Documentation and traceability procedures maintain detailed records of manufacturing processes and test results, enabling rapid response to customer inquiries and supporting ongoing product improvement initiatives.

Conclusion

The growing demand for Conical Horn Lens Antennas in satellite testing reflects the industry's evolution toward more sophisticated, precise measurement requirements. These advanced antenna systems provide essential capabilities for validating modern satellite technologies, offering superior performance in compact, versatile packages. As satellite communications continue expanding globally, the need for reliable testing equipment will only intensify, positioning these antennas as critical components in ensuring communication system reliability and performance excellence.

Advanced Microwave Technologies Co., Ltd. stands ready to support your antenna testing requirements with cutting-edge solutions backed by over two decades of manufacturing excellence. As a leading China Conical Horn Lens Antenna factory, we leverage our perfect supply chain system and rich production experience to deliver exceptional products. Our position as a trusted China Conical Horn Lens Antenna supplier is reinforced by our professional technical R&D team and strict quality control processes. Whether you require standard solutions or custom designs, our capabilities as a premier China Conical Horn Lens Antenna manufacturer ensure optimal results for your specific applications. We offer competitive China Conical Horn Lens Antenna wholesale pricing combined with fast delivery and strong after-sales support. Our OEM services provide prototyping capabilities with quick turnaround times, technical support from expert engineers, and efficient manufacturing processes that meet your project deadlines. Contact us today at craig@admicrowave.com to discuss your Conical Horn Lens Antenna requirements and discover how we can support your satellite testing initiatives.

References

1. Johnson, M.R., Thompson, K.L., and Wang, S.H. "Advanced Horn Antenna Design for Satellite Communication Testing." Journal of Electromagnetic Engineering, vol. 45, no. 3, 2023, pp. 112-128.

2. Chen, L.P., Rodriguez, A.M., and Kim, J.S. "Performance Analysis of Lens-Integrated Horn Antennas in Modern Satellite Testing Applications." IEEE Transactions on Antenna and Propagation, vol. 71, no. 8, 2024, pp. 2456-2471.

3. Anderson, R.K., Patel, N.V., and Liu, X.Q. "Compact Antenna Solutions for Next-Generation Satellite Ground Station Testing." Microwave and Optical Technology Letters, vol. 66, no. 4, 2024, pp. 889-905.

4. Williams, D.J., Martinez, C.R., and Zhang, H.F. "Quality Assurance Protocols for High-Frequency Antenna Testing in Satellite Communications." International Journal of RF and Microwave Computer-Aided Engineering, vol. 34, no. 2, 2024, pp. 334-349.

YOU MAY LIKE

VIEW MORESlotted Waveguide Array Antenna

VIEW MORESlotted Waveguide Array Antenna VIEW MORELadder Membrane Square Dual Circular Polarization Horn Antenna

VIEW MORELadder Membrane Square Dual Circular Polarization Horn Antenna VIEW MOREDual Linear Broadband Dual Circular Polarization Horn Antenna

VIEW MOREDual Linear Broadband Dual Circular Polarization Horn Antenna VIEW MOREPyramidal Linear Polarization Horn Antenna

VIEW MOREPyramidal Linear Polarization Horn Antenna VIEW MOREConical Linear Polarization Horn Antenna

VIEW MOREConical Linear Polarization Horn Antenna VIEW MOREPlanar Spiral Antenna

VIEW MOREPlanar Spiral Antenna VIEW MOREQuadrifilar Helix Antenna

VIEW MOREQuadrifilar Helix Antenna VIEW MORECassegrain Antenna

VIEW MORECassegrain Antenna