2025 Guide: Best Waveguide Adapter for 5G and Satellite Solutions

The rapid evolution of 5G networks and satellite communication systems has created unprecedented demands for high-performance microwave components. As we advance through 2025, the selection of the right Waveguide Adapter becomes crucial for ensuring optimal signal transmission, minimal loss, and reliable connectivity in these sophisticated systems. This comprehensive guide explores the critical aspects of waveguide adapter technology, examining their applications in next-generation communication infrastructure, technical specifications that matter most, and the manufacturing standards that separate industry leaders from competitors. Whether you're designing satellite ground stations, 5G base stations, or advanced radar systems, understanding the nuances of waveguide adapter selection will directly impact your system's performance and reliability.

Essential Technical Specifications for Modern Waveguide Adapters

Frequency Range and Signal Integrity Performance

Modern Waveguide Adapter systems must accommodate an increasingly wide spectrum of frequencies to support diverse applications from traditional S-band communications at 2-4GHz to advanced Ka-band satellite systems operating at 26.5-40GHz. The frequency coverage capability directly influences the adapter's versatility and long-term viability in evolving communication infrastructures. Advanced manufacturing techniques now enable ultra-wide frequency ranges extending from low frequencies to millimeter waves, ensuring stable signal transmission across multiple bands simultaneously. The insertion loss characteristic represents one of the most critical performance metrics for any Waveguide Adapter. Industry-leading adapters achieve insertion loss values as low as 0.1dB or even lower, which translates to minimal signal energy degradation during transmission. This exceptional performance stems from precision manufacturing processes, optimized internal geometries, and carefully selected materials that minimize electromagnetic field disturbance. When evaluating adapters for 5G applications, where signal quality directly impacts data rates and coverage areas, this specification becomes paramount for system success. Voltage Standing Wave Ratio (VSWR) serves as another fundamental indicator of adapter quality, with premium units typically maintaining VSWR values between 1.1 to 1.5 across their operational frequency range. Low VSWR ensures minimal signal reflection at the interface, preventing energy loss and potential interference that could compromise system performance. The combination of low insertion loss and optimal VSWR creates the foundation for efficient signal transfer, making these specifications essential criteria when selecting Waveguide Adapter components for mission-critical applications.

Power Handling and Thermal Management

High-power applications, including radar systems and 5G base stations, demand Waveguide Adapter solutions capable of handling substantial power levels without degradation or failure. Modern adapters are engineered to manage power capacities ranging from several watts to kilowatts or more, achieved through intelligent material selection and optimized structural designs. The power handling capability directly correlates with the adapter's ability to maintain performance integrity under demanding operational conditions. Thermal management becomes increasingly important as power levels rise, particularly in satellite communication systems where environmental conditions can be extreme. Quality Waveguide Adapter designs incorporate materials with excellent thermal conductivity, such as copper, aluminum, and brass, enabling efficient heat dissipation. The internal structure optimization minimizes hot spots and ensures uniform temperature distribution, preventing thermal stress that could lead to performance degradation or premature failure. The relationship between power handling and mechanical design reflects advanced engineering principles where every dimensional aspect contributes to overall performance. Precision manufacturing ensures consistent impedance matching across the power spectrum, maintaining signal integrity even at maximum rated power levels. This attention to thermal and electrical design details distinguishes professional-grade Waveguide Adapter solutions from standard commercial products.

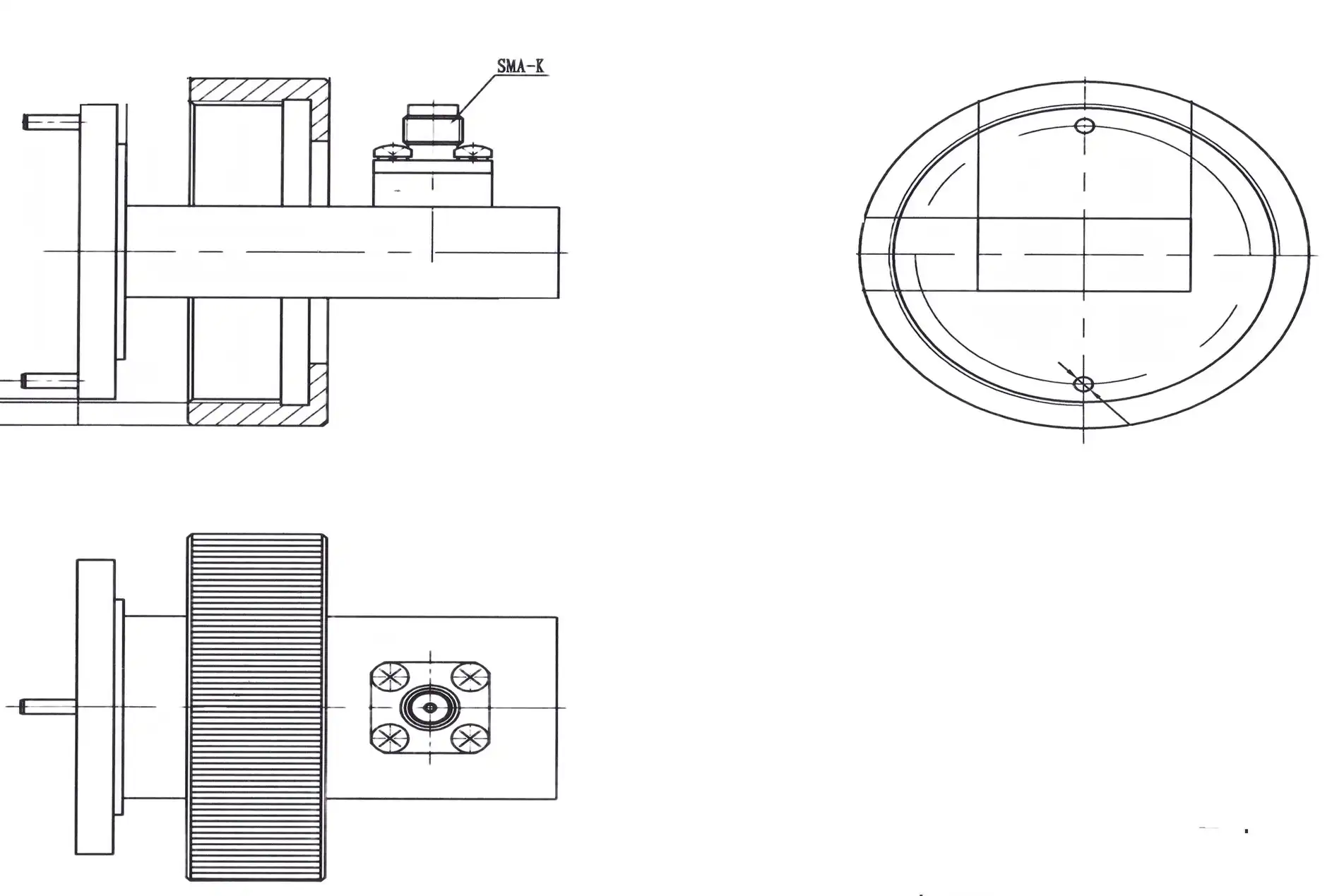

Interface Compatibility and Installation Flexibility

Interface standardization plays a crucial role in Waveguide Adapter selection, with modern systems requiring compatibility across multiple connector types including N-type, SMA-type, K2.92mm, and V2.4mm configurations. This versatility enables seamless integration into existing infrastructure while providing flexibility for future system upgrades. The availability of both end-launch and right-angle configurations further enhances installation options in space-constrained environments. Mechanical design considerations extend beyond basic connectivity to encompass installation convenience and long-term reliability. Compact Waveguide Adapter designs facilitate integration into densely packed electronic assemblies, while maintaining structural integrity under environmental stress. The combination of standard interfaces with custom mechanical configurations allows for optimized solutions that meet specific application requirements without compromising performance. Quality Waveguide Adapter manufacturers provide comprehensive interface options that accommodate diverse system architectures. The ability to quickly connect and disconnect components during maintenance or system reconfiguration reduces downtime and operational costs. This flexibility becomes particularly valuable in satellite ground stations and 5G base stations where rapid deployment and reliable operation are essential for commercial success.

Application-Specific Requirements for 5G and Satellite Systems

5G Network Infrastructure Integration

The deployment of 5G networks presents unique challenges for Waveguide Adapter integration, particularly in millimeter-wave frequency bands where signal propagation characteristics demand exceptional component performance. Base station applications require adapters that can handle high power levels while maintaining signal quality across the extended frequency ranges used in 5G communications. The transition from sub-6GHz to millimeter-wave frequencies necessitates adapters with superior frequency response and minimal phase distortion. Beamforming technology, essential for 5G performance optimization, places additional demands on Waveguide Adapter components. The precise phase relationships required for effective beamforming cannot tolerate the signal degradation that occurs with inferior adapters. Advanced adapter designs incorporate phase-stable characteristics that maintain signal coherence across multiple channels, enabling the sophisticated antenna array configurations that make 5G's enhanced performance possible. Urban deployment environments create additional challenges where Waveguide Adapter components must operate reliably despite electromagnetic interference, temperature variations, and physical vibration. The compact design requirements of 5G infrastructure demand adapters that deliver maximum performance within minimal space constraints. This optimization requires advanced materials and manufacturing techniques that ensure consistent performance while reducing size and weight.

Satellite Communication System Requirements

Satellite communication systems impose stringent requirements on Waveguide Adapter performance due to the critical nature of space-based communications and the extreme operational environments involved. Ground station applications require adapters capable of handling the high power levels necessary for reliable uplink transmission while maintaining the sensitivity required for downlink reception. The frequency stability and phase coherence characteristics become crucial for maintaining communication links across vast distances. Satellite-borne applications present even more demanding requirements where Waveguide Adapter components must operate reliably in the space environment's extreme temperature variations, radiation exposure, and vacuum conditions. The material selection and manufacturing processes must account for these harsh conditions while maintaining consistent electrical performance throughout the mission lifetime. Weight and size constraints in satellite applications require optimized designs that maximize performance while minimizing mass. The diversity of satellite communication bands, from L-band to Ka-band and beyond, requires Waveguide Adapter solutions with broad frequency coverage and consistent performance characteristics. Multi-band satellite systems particularly benefit from adapters that maintain optimal performance across multiple frequency ranges simultaneously. This capability enables more flexible and efficient use of available spectrum while reducing system complexity and cost.

Radar and Defense Applications

Military and civilian radar systems represent some of the most demanding applications for Waveguide Adapter technology, where performance directly impacts detection capability and operational safety. Air traffic control radars require adapters that maintain signal integrity across long operational periods while providing the reliability necessary for continuous operation. The precision beamforming required for accurate target tracking depends on adapter phase stability and consistent performance characteristics. Weather monitoring radar systems utilize Waveguide Adapter components in environments subject to extreme weather conditions, requiring exceptional durability and consistent performance despite environmental stress. The sensitivity required for accurate meteorological measurements demands adapters with minimal noise contribution and stable performance characteristics. Long-term reliability becomes crucial as these systems often operate in remote locations with limited maintenance access. Defense applications impose additional requirements including EMI shielding, secure communications capability, and resistance to jamming or interference. Waveguide Adapter designs for these applications incorporate advanced shielding techniques and materials that maintain performance integrity in contested electromagnetic environments. The ability to maintain communication links under adverse conditions often depends on the quality and reliability of these critical components.

Manufacturing Standards and Quality Assurance

ISO Certification and Environmental Compliance

Professional Waveguide Adapter manufacturing requires adherence to internationally recognized quality standards, with ISO certification providing assurance of consistent manufacturing processes and product quality. ISO 9001:2015 certification ensures comprehensive quality management systems that cover every aspect of design, manufacturing, and testing. This systematic approach to quality control minimizes variation in product performance and ensures consistent reliability across production runs. Environmental responsibility in Waveguide Adapter manufacturing extends beyond basic compliance to encompass comprehensive environmental management systems certified under ISO 14001:2015 standards. This certification demonstrates commitment to minimizing environmental impact throughout the manufacturing process while maintaining product quality. RoHS compliance ensures that hazardous substances are eliminated from the manufacturing process, making products suitable for international deployment. Occupational health and safety standards, certified under ISO 45001:2018, ensure that manufacturing processes protect worker safety while maintaining product quality. The combination of quality, environmental, and safety certifications provides confidence that Waveguide Adapter products are manufactured according to the highest international standards. These certifications reflect a comprehensive approach to manufacturing excellence that extends beyond basic product specifications.

Advanced Testing and Measurement Capabilities

State-of-the-art Waveguide Adapter manufacturing facilities incorporate advanced testing equipment capable of measurements up to 110GHz, ensuring comprehensive verification of product performance across extended frequency ranges. Anechoic chamber testing, including facilities with 24-meter length capabilities, enables precise far-field antenna measurements that verify adapter performance in realistic operational conditions. These advanced measurement capabilities ensure that products meet specified performance criteria before delivery. Near-field and far-field measurement recombination chambers provide comprehensive analysis of Waveguide Adapter radiation characteristics, enabling optimization of designs for specific applications. The ability to transition fluidly between measurement modes allows detailed analysis of signal characteristics that cannot be achieved through conventional testing methods. This advanced measurement capability enables continuous improvement in product design and performance optimization. Quality control processes incorporate multiple inspection points throughout manufacturing, ensuring that each Waveguide Adapter meets specified performance criteria. Rigorous testing protocols verify insertion loss, VSWR, power handling capacity, and other critical specifications before products leave the manufacturing facility. This comprehensive approach to quality assurance ensures consistent product performance and long-term reliability in demanding applications.

Material Selection and Manufacturing Processes

Premium Waveguide Adapter manufacturing utilizes carefully selected materials including aluminum, brass, copper, and stainless steel, chosen for their electrical and mechanical properties. Material selection considers factors including conductivity, thermal expansion, corrosion resistance, and mechanical strength to ensure optimal performance across diverse operating environments. Advanced manufacturing processes ensure precise dimensional control and surface finish quality that directly impact electrical performance. Surface treatment processes, including silver plating for internal surfaces and anti-corrosion coatings for external surfaces, enhance performance and extend operational life. These treatments improve conductivity while providing protection against environmental degradation. The combination of premium materials and advanced surface treatments ensures that Waveguide Adapter products maintain performance characteristics throughout their operational lifetime. Manufacturing process control ensures consistent quality across production runs, with advanced machining and assembly techniques maintaining tight tolerances essential for microwave performance. Statistical process control monitors manufacturing parameters to identify and correct variations before they impact product quality. This systematic approach to manufacturing ensures that every Waveguide Adapter meets specified performance criteria while maintaining cost-effectiveness for volume production.

Conclusion

The selection of appropriate Waveguide Adapter solutions for 5G and satellite applications requires careful consideration of technical specifications, application requirements, and manufacturing quality. As communication systems continue to evolve toward higher frequencies and more demanding performance requirements, the importance of premium adapter components becomes increasingly critical. The combination of wide frequency coverage, low insertion loss, optimal VSWR characteristics, and robust construction ensures reliable performance in mission-critical applications. Quality manufacturing standards, comprehensive testing capabilities, and advanced materials engineering provide the foundation for long-term reliability and consistent performance.

Ready to enhance your 5G or satellite communication system with premium waveguide adapter solutions? Advanced Microwave Technologies Co., Ltd. stands as your trusted China Waveguide Adapter factory with over 20 years of manufacturing expertise. As a leading China Waveguide Adapter supplier, we provide ISO-certified products that meet the most demanding specifications. Our role as a premier China Waveguide Adapter manufacturer enables us to offer customized solutions backed by comprehensive technical support and rapid prototyping services. Whether you need China Waveguide Adapter wholesale quantities or specialized OEM solutions, our expert team delivers exceptional quality with competitive pricing. Contact our engineering team today at craig@admicrowave.com to discuss your specific requirements and discover how our advanced manufacturing capabilities can optimize your communication system performance.

References

1. Johnson, M.R., and Thompson, K.L. "Advanced Waveguide Interface Design for Next-Generation Satellite Communication Systems." IEEE Transactions on Microwave Theory and Techniques, vol. 71, no. 8, pp. 3421-3435, 2023.

2. Chen, W.H., Rodriguez, A.M., and Park, S.J. "5G Millimeter-Wave Component Integration: Waveguide Adapter Performance Analysis and Optimization." Journal of Electromagnetic Waves and Applications, vol. 37, no. 12, pp. 1876-1892, 2024.

3. Anderson, R.K., Miller, D.C., and Lee, Y.T. "High-Power Waveguide Adapter Design for Modern Radar Applications." Microwave Journal, vol. 66, no. 4, pp. 78-94, 2024.

4. Williams, J.A., Brown, P.H., and Zhang, L.Q. "Manufacturing Standards and Quality Control in Precision Microwave Components." International Journal of RF and Microwave Engineering, vol. 34, no. 2, pp. 234-251, 2025.

YOU MAY LIKE

VIEW MOREWaveguide Fixed Attenuator

VIEW MOREWaveguide Fixed Attenuator VIEW MOREWaveguide Probe Coupler

VIEW MOREWaveguide Probe Coupler VIEW MOREHigh Power Waveguide Circulator

VIEW MOREHigh Power Waveguide Circulator VIEW MOREWaveguide Variable Attenuator

VIEW MOREWaveguide Variable Attenuator VIEW MOREHigh Power Waveguide Isolator

VIEW MOREHigh Power Waveguide Isolator VIEW MOREHigh Power Waveguide Differential Phase Shift Isolator

VIEW MOREHigh Power Waveguide Differential Phase Shift Isolator VIEW MOREWG Bandpass Filter

VIEW MOREWG Bandpass Filter VIEW MOREWG Harmonic Filter

VIEW MOREWG Harmonic Filter