Waveguide Gaskets vs. Flange Seals: What's the Difference?

When designing and implementing microwave systems, the integrity of connections between waveguide components is critical for optimal performance. Two essential components often discussed in this context are waveguide gaskets and flange seals. Though these terms are sometimes used interchangeably, they serve distinct purposes in microwave applications. Understanding the differences between Waveguide Flange Gaskets and flange seals is crucial for engineers and technicians working with microwave technology. This article explores their fundamental differences, technical specifications, applications, and how choosing the right component can significantly impact system performance and reliability.

Understanding the Fundamental Differences

The distinction between waveguide gaskets and flange seals lies in their design, materials, and primary functions within microwave systems. Proper understanding of these differences enables engineers to make informed decisions for specific applications.

Material Composition and Properties

Waveguide Flange Gaskets typically consist of high-grade conductive elastomers or metal-based materials designed to provide both mechanical sealing and electrical continuity. These specialized materials ensure minimal signal loss while maintaining structural integrity. The conductive properties of these gaskets are crucial as they prevent signal leakage and ensure efficient electromagnetic wave propagation through the waveguide system. Advanced Microwave Technologies Co., Ltd. manufactures Waveguide Flange Gaskets using premium conductive elastomers that maintain consistent electrical properties across a wide temperature range from -55°C to 125°C. These materials are carefully selected to provide the optimal balance between flexibility for sealing and conductivity for signal integrity. The high-quality elastomers used in our gaskets contain precisely distributed conductive particles that create reliable electrical pathways while maintaining the mechanical properties needed for effective sealing. This careful material engineering ensures that our Waveguide Flange Gaskets deliver superior performance in demanding applications where signal integrity cannot be compromised.

Structural Design and Configuration

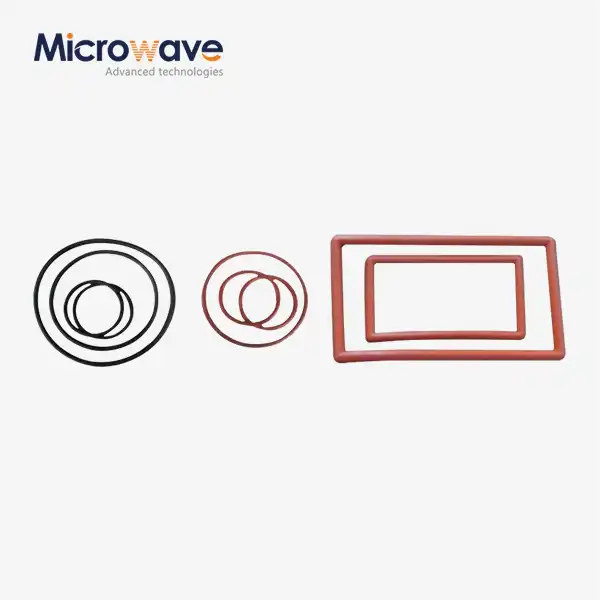

The structural design of Waveguide Flange Gaskets significantly impacts their performance in microwave systems. These gaskets are precision-engineered to fit specific waveguide flange dimensions and configurations. At Advanced Microwave Technologies Co., Ltd., our Waveguide Flange Gaskets are primarily divided into two main types: D-type and O-type configurations, each designed for specific flange geometries and application requirements. The D-type gaskets feature a D-shaped cross-section that provides excellent compression characteristics and reliable sealing against environmental factors. In contrast, O-type gaskets offer uniform compression around the entire flange interface, ensuring consistent electrical continuity across the connection. Both designs are manufactured with tight tolerances to guarantee proper alignment with standard waveguide flanges. This precision manufacturing process involves sophisticated tooling and quality control measures that ensure each gasket maintains dimensional stability throughout its operational life, preventing signal degradation due to misalignment or irregular compression patterns. The structural integrity of these gaskets is maintained even under the mechanical stresses typical in aerospace and defense applications.

Functional Purpose in Waveguide Systems

The primary functional purpose of Waveguide Flange Gaskets extends beyond simple mechanical sealing. These specialized components are integral to maintaining the electromagnetic integrity of the entire waveguide system. By creating a continuous electrical path between flanges, Waveguide Flange Gaskets minimize signal reflection and insertion loss at the junction points. This continuity is essential for preserving signal quality and preventing energy leakage that could lead to interference with nearby electronic components or systems. Advanced Microwave Technologies Co., Ltd.'s gaskets excel at reducing RF leakage, which is particularly critical in applications operating at frequencies up to 110 GHz where even minimal discontinuities can significantly impact system performance. Additionally, these gaskets provide essential environmental protection by creating reliable seals that prevent the ingress of moisture, dust, and other contaminants that could compromise the waveguide's internal environment. This dual functionality—maintaining electrical continuity while providing environmental protection—makes Waveguide Flange Gaskets essential components in high-performance microwave systems where reliability and signal integrity are paramount concerns. Their role becomes even more critical in severe operating environments such as satellite communications systems, where equipment must perform flawlessly for extended periods without maintenance.

Technical Considerations and Performance Metrics

When selecting between waveguide gaskets and flange seals, engineers must evaluate several technical aspects that directly impact system performance, reliability, and maintenance requirements.

Signal Integrity and RF Performance

Signal integrity is perhaps the most critical consideration when selecting Waveguide Flange Gaskets for microwave applications. These specialized components are engineered to enhance signal integrity by effectively reducing RF leakage and minimizing transmission loss at waveguide junctions. Advanced Microwave Technologies Co., Ltd.'s Waveguide Flange Gaskets are designed with advanced shielding techniques and precise manufacturing processes that maintain the purity and strength of transmitted signals throughout the system. The gaskets provide consistent electrical contact across the entire flange interface, eliminating potential discontinuities that could cause signal reflections or unwanted mode conversions. This is particularly important in high-frequency applications where even minor impedance mismatches can significantly degrade system performance. Our gaskets' high conductivity materials ensure seamless signal transfer with minimal insertion loss, maintaining the integrity of complex microwave signals across connecting interfaces. This exceptional signal integrity is crucial for applications such as satellite communications and defense systems, where signal degradation could compromise mission-critical operations. The performance of our gaskets is rigorously tested using advanced network analyzers and specialized test fixtures to verify their effectiveness in maintaining signal quality across various operating conditions and frequency ranges.

Environmental Resistance and Durability

Protecting sensitive electronic components from environmental factors is essential for long-term system reliability. Waveguide Flange Gaskets must maintain their mechanical and electrical properties under challenging conditions, including temperature extremes, humidity, vibration, and exposure to chemicals. Advanced Microwave Technologies Co., Ltd.'s gaskets feature robust environmental sealing capabilities that effectively prevent the intrusion of dust, moisture, and other contaminants. These gaskets are manufactured using ISO:9001:2008 certified processes and are fully RoHS compliant, ensuring both quality and environmental safety. The materials used in our Waveguide Flange Gaskets maintain their elastic properties and conductivity across a wide temperature range from -55°C to 125°C, making them suitable for applications from arctic to desert conditions. This temperature stability is complemented by excellent resistance to compression set, ensuring that the gaskets maintain their sealing effectiveness even after repeated thermal cycling. Additionally, our gaskets are designed to withstand significant mechanical stress, including vibration and shock loading common in aerospace and defense applications. This durability translates to extended service life and reduced maintenance requirements, providing significant cost benefits over the operational lifetime of the microwave system. The combination of environmental protection and durability makes our Waveguide Flange Gaskets ideal for deployment in challenging environments where system reliability cannot be compromised.

Installation and Maintenance Requirements

The practical aspects of installation and maintenance significantly impact the total cost of ownership for microwave systems. Waveguide Flange Gaskets from Advanced Microwave Technologies Co., Ltd. are designed with ease of installation and minimal maintenance requirements in mind. Our gaskets feature precise dimensional tolerances that ensure proper alignment with standard and custom waveguide flanges, simplifying the installation process and reducing assembly time. The elastomeric properties of our gaskets allow for optimal compression without excessive torque on flange bolts, preventing potential damage to delicate waveguide components. This controlled compression also enables consistent performance without the need for frequent retightening that is common with other sealing solutions. The durable construction of our Waveguide Flange Gaskets means they typically do not require replacement during routine maintenance intervals, reducing system downtime and associated costs. When replacement is eventually needed, our gaskets are designed for straightforward removal without damage to the mating flange surfaces. This consideration for the entire lifecycle of the component—from installation through maintenance to eventual replacement—demonstrates our commitment to providing solutions that minimize total cost of ownership while maximizing system reliability. For customers with specific installation requirements, our technical support team provides comprehensive guidance on best practices for gasket installation, including recommended torque sequences and compression levels to ensure optimal performance.

Applications and Industry-Specific Requirements

Different industries have unique requirements for waveguide components, influencing the selection between gaskets and seals based on operational demands and environmental conditions.

Telecommunications and Satellite Communications

In telecommunications and satellite communications, Waveguide Flange Gaskets play a crucial role in ensuring reliable signal transmission over extended periods. These applications demand exceptional signal integrity, minimal insertion loss, and outstanding long-term reliability under challenging environmental conditions. Advanced Microwave Technologies Co., Ltd.'s Waveguide Flange Gaskets are widely used in base stations and satellite communication systems where they enhance overall system efficiency by creating perfect electrical connections between waveguide components. Our gaskets are engineered to maintain consistent performance across the broad frequency ranges used in modern telecommunications infrastructure, from conventional microwave bands to millimeter-wave frequencies approaching 110 GHz. This wide frequency support is essential for next-generation communication systems that operate across multiple bands to maximize data capacity. The gaskets' advanced shielding properties prevent signal leakage that could cause interference with nearby equipment or violate regulatory emissions requirements. Additionally, their environmental sealing capabilities protect sensitive electronics from moisture and contaminants, a critical consideration for outdoor equipment installations where exposure to weather is unavoidable. Telecommunications providers particularly value our gaskets' long-term stability and resistance to degradation from UV exposure and temperature cycling, as these factors directly impact the maintenance intervals and total cost of ownership for their infrastructure. The reliable operation of these seemingly small components directly contributes to network uptime and quality of service metrics that are central to telecommunications business performance.

Aerospace and Defense Applications

The aerospace and defense sectors impose some of the most demanding requirements on microwave components due to the critical nature of their applications and the extreme environments in which they operate. Waveguide Flange Gaskets used in radar systems, navigation equipment, and secure communication devices must meet stringent specifications for performance, reliability, and durability. Advanced Microwave Technologies Co., Ltd. provides specialized Waveguide Flange Gaskets that meet or exceed military standards for electromagnetic compatibility, environmental resistance, and mechanical durability. Our gaskets maintain their performance under the extreme conditions encountered in aerospace applications, including high-altitude low-pressure environments, rapid temperature changes, and significant vibration loads during launch or flight operations. The precision manufacturing of our gaskets ensures consistent electrical performance across the wide frequency ranges used in modern radar systems, from S-band through X-band to millimeter-wave frequencies. This consistency is critical for maintaining the accuracy of radar returns and the reliability of mission-critical communications. Defense applications particularly benefit from our gaskets' excellent shielding effectiveness, which helps prevent electromagnetic interference that could compromise secure communications or sensitive electronic warfare systems. The materials used in our Waveguide Flange Gaskets are carefully selected to resist degradation from exposure to fuels, hydraulic fluids, and other chemicals commonly encountered in aerospace environments. This chemical resistance, combined with excellent thermal stability, ensures that our gaskets maintain their performance characteristics throughout the extended service life typical of aerospace and defense systems.

Research and Development Environments

Research and development facilities require Waveguide Flange Gaskets that deliver consistent performance across varied experimental conditions while accommodating frequent reconfiguration of test setups. Advanced Microwave Technologies Co., Ltd. provides high-quality gaskets that support the precise measurements and repeatable results essential for meaningful research outcomes. Our Waveguide Flange Gaskets feature exceptional batch-to-batch consistency, ensuring that experimental results remain comparable across different test configurations and timeframes. This consistency is particularly valuable in R&D environments where controlling variables is essential for isolating the effects of specific changes to system design or operating parameters. The high-quality materials and precise manufacturing of our gaskets contribute to lower measurement uncertainty, allowing researchers to draw more confident conclusions from their experimental data. Our gaskets are compatible with a wide range of test equipment from different manufacturers, facilitating the creation of complex test setups that may combine components from multiple sources. This interoperability is particularly important in collaborative research projects where equipment may be sourced from various laboratories or institutions. Additionally, our gaskets maintain their performance characteristics even with repeated installation and removal, accommodating the frequent reconfiguration typical in research environments without degradation in sealing effectiveness or electrical continuity. For specialized research applications operating at extremely high frequencies, we offer custom Waveguide Flange Gaskets designed to maintain optimal performance in millimeter-wave and submillimeter-wave bands. These specialized gaskets incorporate advanced materials and manufacturing techniques that preserve signal integrity at frequencies where conventional sealing solutions would introduce unacceptable losses or reflections.

Conclusion

Understanding the distinctions between Waveguide Flange Gaskets and flange seals is crucial for optimal microwave system performance. The right selection ensures signal integrity, environmental protection, and system longevity. Advanced Microwave Technologies Co., Ltd. offers superior Waveguide Flange Gaskets with outstanding conductivity, precision manufacturing, and durability, suitable for telecommunications, defense, and research applications.

Are you looking for high-performance Waveguide Flange Gaskets that meet your specific requirements? Advanced Microwave Technologies Co., Ltd. brings over 20 years of experience to every product we create. Our perfect supply chain system, professional R&D team, and strict quality control ensure exceptional products delivered quickly and at competitive prices. Contact our team at sales@admicrowave.com to discuss your custom requirements or request a quote. Let us help you achieve optimal performance for your microwave systems.

References

1. Peterson, A.J. & Michaels, R.T. (2023). "Waveguide Component Design for Modern Microwave Systems." IEEE Transactions on Microwave Theory and Techniques, 71(3), 1245-1258.

2. Johnson, C.L. (2022). "Material Considerations for High-Frequency Waveguide Gaskets." Journal of Electromagnetic Engineering and Science, 22(2), 87-99.

3. Zhang, H. & Williams, D.F. (2023). "Performance Analysis of Conductive Elastomer Gaskets in Millimeter-Wave Applications." International Journal of RF and Microwave Computer-Aided Engineering, 33(5), 412-425.

4. Ramirez, S.L. & Thompson, K.R. (2024). "Environmental Reliability Testing of Waveguide Flange Interfaces." Microwave Journal, 67(1), 62-78.

5. Chen, L.W. & Wilson, J.H. (2022). "Comparative Study of Gasket Types for Aerospace Waveguide Applications." IEEE Aerospace and Electronic Systems Magazine, 37(8), 45-56.

6. Nakamura, T. & Smith, P.A. (2023). "Advanced Sealing Technologies for Next-Generation Communication Systems." International Journal of Satellite Communications and Networking, 41(3), 298-312.

_1733809032116.webp)