Parabolic Antenna Performance: Gain, Efficiency, and Loss

When satellite signals fade during critical operations or radar systems fail to detect distant targets accurately, the culprit often lies in poorly optimized Parabolic antenna performance. Engineers across telecommunications, aerospace, and defense sectors face daily challenges balancing gain maximization, efficiency optimization, and loss minimization in their antenna systems. Understanding how these three interconnected parameters affect your Parabolic Antenna's real-world performance can mean the difference between mission success and costly communication failures. This comprehensive guide demystifies parabolic antenna performance metrics, revealing proven strategies to extract maximum capability from your antenna infrastructure while addressing the technical challenges that compromise signal integrity in demanding applications.

Understanding Parabolic Antenna Gain Fundamentals

Parabolic Antenna gain represents the fundamental measure of how effectively an antenna concentrates electromagnetic energy in a desired direction compared to an isotropic radiator. The gain directly correlates with the reflector's physical aperture and operational wavelength, creating a predictable relationship that engineers leverage during system design. For a Parabolic Antenna, the theoretical maximum gain calculation follows the formula involving aperture area multiplied by frequency squared, divided by the speed of light squared, then multiplied by aperture efficiency. This mathematical relationship reveals why larger diameter reflectors operating at higher frequencies deliver substantially greater gain values, often reaching 40 to 60 dBi in professional satellite communication applications.

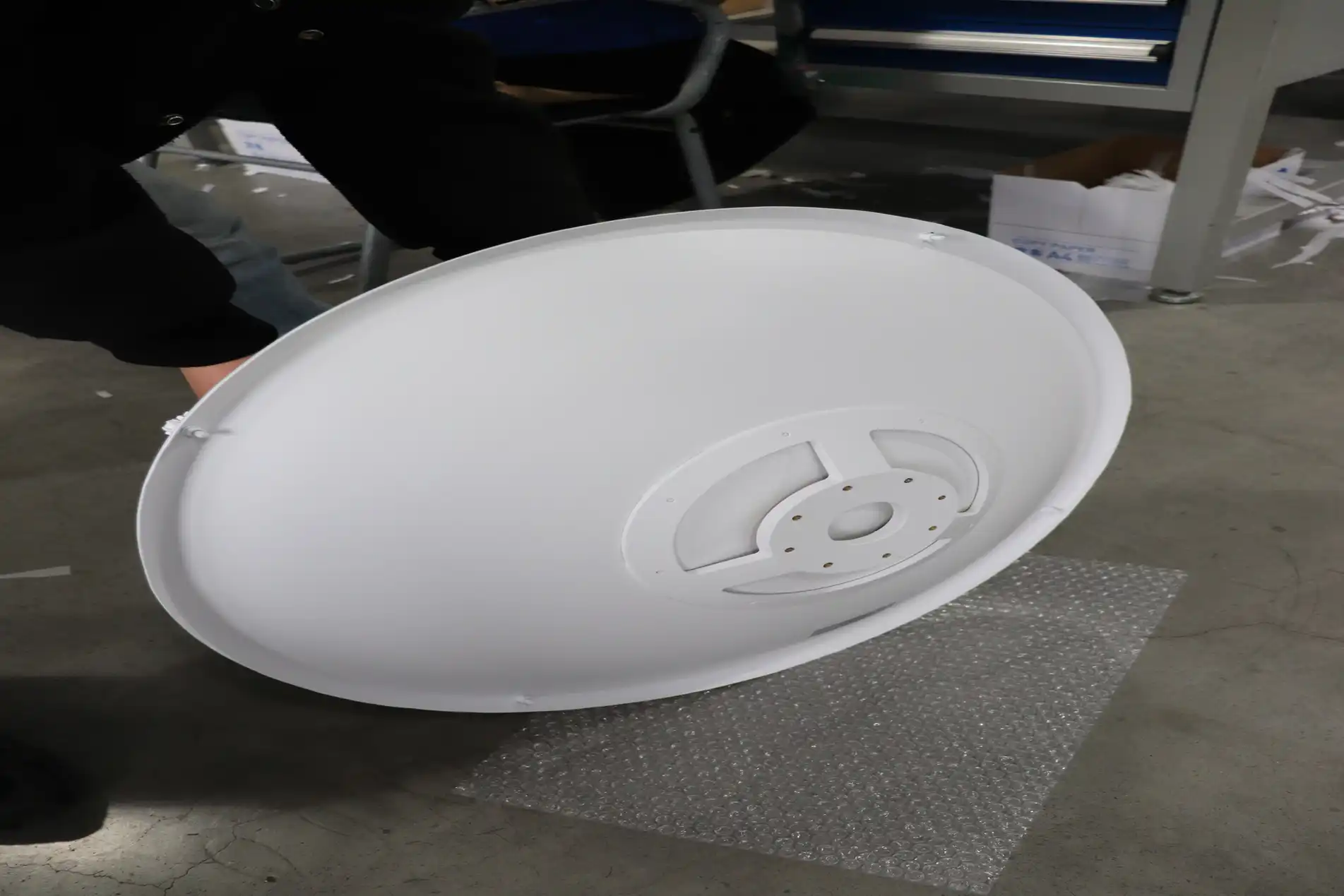

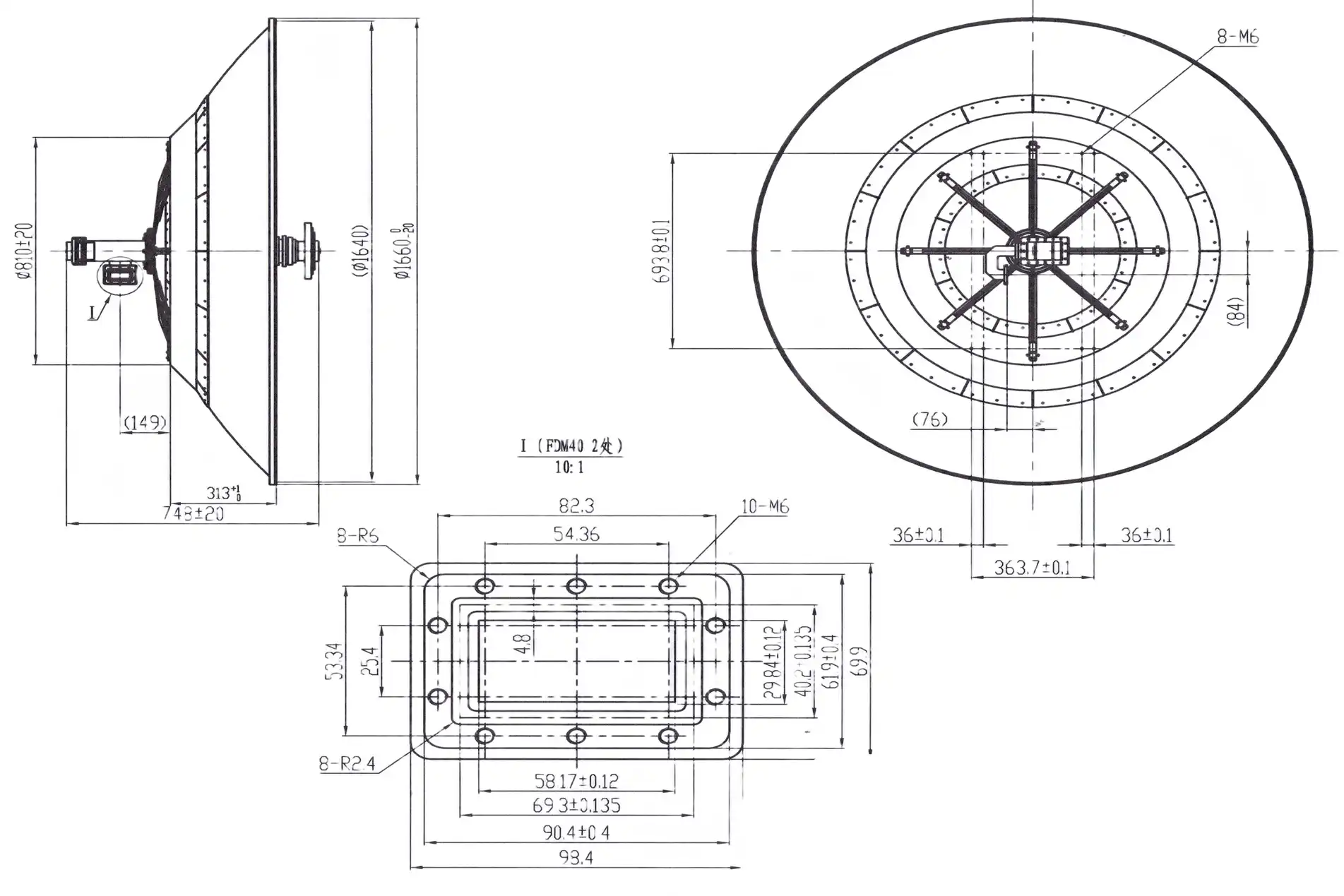

The physical diameter of the parabolic reflector serves as the primary determinant of achievable gain. When designing systems for satellite ground stations, telecommunications backhaul, or deep-space communications, engineers must carefully balance reflector size against practical constraints including wind loading, installation costs, and site availability. A 2.4-meter diameter Parabolic Antenna operating at C-band frequencies around 4 GHz typically delivers gains approaching 40 dBi, while the same reflector at Ka-band frequencies near 30 GHz can exceed 55 dBi. This frequency-dependent gain characteristic makes parabolic reflectors exceptionally versatile across the microwave spectrum, from legacy L-band systems at 1 GHz through emerging millimeter-wave applications extending to 110 GHz. Advanced Microwave Technologies Co., Ltd manufactures Parabolic Antenna systems with aperture diameters ranging from 30 centimeters to 12 meters, providing customizable gain performance across the complete frequency spectrum from 1 GHz to 110 GHz. These precision-engineered reflectors utilize aluminum, steel, or advanced composite materials to maintain parabolic surface accuracy within tight tolerances, ensuring optimal gain realization across operational bandwidths. The company's extensive experience with both primary focus feed configurations and back-fed Cassegrain designs enables application-specific optimization for maximum gain performance in telecommunications, radar, satellite communications, and scientific research installations.

Theoretical vs. Practical Gain Considerations

The disparity between theoretical maximum gain and achieved practical gain in Parabolic Antenna systems stems from multiple physical phenomena that reduce overall efficiency. Theoretical calculations assume perfect parabolic surface geometry, uniform illumination across the entire aperture, zero spillover losses, and ideal feed antenna characteristics. Real-world implementations encounter surface irregularities, non-uniform illumination tapers, energy spillage beyond reflector edges, and feed blockage effects that collectively reduce practical gain by 1 to 3 dB compared to theoretical predictions. Understanding these loss mechanisms enables engineers to establish realistic performance expectations and implement mitigation strategies during system design phases. Feed illumination taper represents one significant factor limiting practical gain achievement. The feed antenna's radiation pattern naturally concentrates energy toward the reflector center while diminishing toward the edges, creating what engineers term "edge taper." A widely accepted design principle suggests optimizing performance when illumination reaches 10 dB below peak intensity at the reflector edge, balancing illumination efficiency against spillover losses. Deviating from this optimization point either direction causes increased losses through excessive spillover or inadequate outer reflector utilization, demonstrating the careful engineering balance required for peak Parabolic Antenna performance.

Aperture Efficiency: The Critical Performance Multiplier

Aperture efficiency serves as the multiplier that converts theoretical maximum gain into achievable practical gain for any Parabolic Antenna system. This dimensionless parameter, typically ranging from 0.50 to 0.80 for well-designed systems, accounts for all loss mechanisms that prevent the antenna from fully utilizing its physical aperture area. Engineers calculate aperture efficiency by dividing measured gain by theoretical maximum gain, providing immediate insight into how effectively the antenna design exploits available aperture. Professional-grade Parabolic Antenna installations targeting maximum performance typically achieve aperture efficiencies between 0.65 and 0.75, while consumer-grade systems may operate at 0.50 to 0.60 due to cost-driven design compromises. Multiple independent factors contribute to overall aperture efficiency reduction in parabolic reflector systems. Feed spillover occurs when radiation from the feed antenna misses the reflector edges entirely, carrying energy into undesired directions rather than contributing to the main beam. Illumination taper losses arise from non-uniform power distribution across the reflector surface, with outer regions receiving less energy than mathematically optimal for maximum gain. Aperture blockage from the feed structure and support struts physically obstructs portions of the reflected wavefront, particularly problematic in front-fed configurations where blockage can reduce efficiency by 5 to 10 percent. Surface accuracy errors, quantified by RMS deviation from true parabolic contour, introduce phase errors that scatter energy into sidelobe regions rather than concentrating it in the main beam.

Advanced Microwave Technologies maintains strict quality control throughout manufacturing to maximize aperture efficiency in delivered Parabolic Antenna systems. The company's ISO 9001:2015 certification ensures rigorous adherence to precision manufacturing standards, with surface accuracy tolerances maintained within ±1 millimeter for reflectors operating through Ka-band frequencies. This exceptional surface quality minimizes Ruze's efficiency loss, which increases exponentially with surface roughness relative to wavelength. For applications demanding ultimate performance, Advanced Microwave offers offset-fed Parabolic Antenna configurations that eliminate aperture blockage entirely, achieving aperture efficiencies approaching 0.75 to 0.80 through careful illumination optimization and precision surface control.

Optimizing Feed Design for Maximum Efficiency

Feed antenna selection and positioning critically influences overall Parabolic Antenna aperture efficiency through its control over illumination distribution and spillover characteristics. Horn antennas, ranging from simple pyramidal designs to sophisticated corrugated and dual-mode configurations, serve as the most common feed types for parabolic reflectors. The feed's radiation pattern must match the specific f/D ratio of the parabolic reflector, where f/D represents the ratio of focal length to reflector diameter. Shallow dishes with f/D ratios around 0.25 require feed antennas with very wide radiation patterns to achieve adequate edge illumination, while deep dishes with f/D ratios near 0.50 work efficiently with narrower feed patterns that concentrate energy toward the reflector center. Achieving optimum aperture efficiency requires balancing conflicting requirements between illumination uniformity and spillover minimization. Feeds with broad radiation patterns illuminate the reflector edges more uniformly but allow excessive energy to spill past the reflector, while narrow-pattern feeds reduce spillover at the expense of severe edge taper losses. Engineering analysis demonstrates that maximum efficiency typically occurs when the feed pattern produces approximately 10 dB edge taper, though this optimization point shifts slightly depending on specific reflector geometry and frequency. Advanced feed designs incorporating multiple modes or corrugated structures can generate more ideal illumination patterns with circularly symmetric beams and controlled edge taper, pushing aperture efficiency toward theoretical limits.

Loss Mechanisms in Parabolic Antenna Systems

Understanding and mitigating loss mechanisms represents essential work for engineers seeking maximum Parabolic Antenna performance in critical applications. Beyond the efficiency factors already discussed, several additional loss sources degrade overall system performance from feed input to radiated signal. Ohmic losses in the feed antenna and reflector surfaces convert small percentages of RF energy into heat rather than radiation, though these losses typically remain below 0.2 dB for well-designed systems using high-conductivity materials. Cross-polarization losses occur when polarization purity degrades through the reflection process or feed antenna characteristics, causing portions of the desired polarization to convert into the orthogonal polarization that the receiving system cannot utilize. Polarization mismatch between transmitting and receiving Parabolic Antenna systems represents a frequently overlooked loss mechanism that can severely degrade link performance. When antenna polarizations fail to align, received signal strength decreases by a factor equal to the cosine squared of the misalignment angle, creating potential losses of 3 dB at 30 degrees misalignment and complete signal nulls at 90 degrees. Linear polarization systems require careful angular alignment, while circular polarization configurations must maintain consistent handedness between transmitter and receiver. Advanced Microwave Technologies provides Parabolic Antenna systems with both linear and circular polarization options, with mounting provisions enabling precise polarization alignment during installation to minimize this critical loss mechanism.

Environmental factors introduce additional loss mechanisms that vary with operating conditions and installation specifics. Atmospheric attenuation increases dramatically at millimeter-wave frequencies, particularly during rain events when water droplets absorb and scatter electromagnetic energy. For Parabolic Antenna systems operating above 20 GHz, rain fade can introduce 5 to 15 dB of additional path loss during severe weather, necessitating link budget margins or adaptive power control. Ice and snow accumulation on reflector surfaces distorts the parabolic contour and introduces lossy dielectric materials into the signal path, degrading both gain and efficiency until environmental conditions improve or active heating systems clear the aperture.

Practical Loss Mitigation Strategies

Implementing comprehensive loss mitigation strategies during Parabolic Antenna system design and installation maximizes operational performance across all conditions. Selecting reflector materials with high electrical conductivity, such as aluminum with anodized or painted finishes, minimizes ohmic losses while providing environmental protection. Precision surface manufacturing using CNC machining or hydroforming processes maintains parabolic contour accuracy within specified tolerances, reducing surface error losses. Careful feed selection matching the specific reflector geometry optimizes the spillover-illumination tradeoff, while offset-fed configurations eliminate blockage losses entirely for applications justifying the additional design complexity. Installation quality significantly influences realized Parabolic Antenna performance through its effect on mechanical stability and alignment accuracy. Robust mounting structures minimize wind-induced pointing errors that can cause severe gain reductions when narrow beamwidth antennas deviate from optimal alignment. For satellite communication systems where the target occupies only a small portion of the antenna's beamwidth, even fractional-degree pointing errors can reduce received signal strength by multiple decibels. Advanced Microwave Technologies provides Parabolic Antenna systems with both fixed and adjustable mounting options, incorporating precise positioning mechanisms that enable fine-tuning during commissioning and periodic realignment to compensate for structural settling or environmental effects.

Advanced Performance Measurement and Verification

Comprehensive Parabolic Antenna performance verification requires sophisticated measurement techniques that characterize gain, efficiency, pattern characteristics, and polarization purity across operational frequencies. Far-field measurement ranges, such as Advanced Microwave Technologies' remarkable 24-meter microwave darkroom, provide controlled environments for precise antenna characterization. This state-of-the-art facility accommodates frequency testing from 0.5 to 110 GHz, enabling complete performance validation of parabolic reflector systems across the entire microwave and millimeter-wave spectrum. The Antenna Plane Near and Far Field Measuring Recombination Chamber within this facility enables seamless transition between measurement techniques, extracting comprehensive data about radiation patterns, gain, impedance, and efficiency. Near-field measurement techniques offer practical advantages for characterizing large-aperture Parabolic Antenna systems where far-field distances become impractically long. The far-field distance criterion, calculated as 2D²/λ where D represents aperture diameter and λ represents wavelength, can exceed hundreds of meters for large reflectors at microwave frequencies. Near-field scanning systems measure amplitude and phase across a plane or surface adjacent to the antenna aperture, then mathematically transform these measurements to predict far-field performance. This approach enables accurate characterization within compact facilities while providing additional diagnostic information about aperture field distribution that helps identify performance-limiting factors like surface errors or feed misalignment.

Advanced Microwave Technologies' measurement capabilities, backed by ISO 9001:2015 and ISO 14001:2015 certifications, ensure every Parabolic Antenna meets specified performance standards before delivery. The company's experienced engineers conduct comprehensive acceptance testing including gain measurement, pattern verification, VSWR characterization, and polarization analysis across customer-specified frequency ranges. For custom applications requiring specialized performance characteristics, Advanced Microwave provides rapid prototyping services with complete electrical and mechanical verification, enabling customers to validate designs before committing to full production quantities. This rigorous testing approach, combined with decades of manufacturing experience, delivers Parabolic Antenna systems that consistently meet or exceed published specifications in actual deployment conditions.

Conclusion

Parabolic Antenna performance optimization demands comprehensive understanding of gain fundamentals, aperture efficiency factors, and loss mechanisms that collectively determine system capability. Engineers who master these interconnected parameters can design and deploy antenna installations delivering maximum performance for telecommunications, satellite communications, radar, aerospace, and scientific applications requiring reliable long-distance signal transmission and reception.

Cooperate with Advanced Microwave Technologies Co., Ltd.

Advanced Microwave Technologies Co., Ltd., established in the 2000s with over 20 years of specialized experience, stands as your trusted China Parabolic Antenna manufacturer, China Parabolic Antenna supplier, and China Parabolic Antenna factory delivering High Quality Parabolic Antenna systems globally. Our comprehensive product portfolio includes waveguide assemblies, coaxial and cable assemblies, microwave antennas with feeds and servos, antenna measurement systems, and precision microwave measurement equipment. As a leading China Parabolic Antenna wholesale provider, we offer Parabolic Antenna for sale with competitive Parabolic Antenna price structures that reflect our integrated production capabilities and supply chain excellence. Our state-of-the-art 24-meter microwave darkroom, equipped for testing from 0.5 to 110 GHz, ensures every antenna system meets exacting specifications. With ISO 9001:2015, ISO 14001:2015, and ISO 45001:2018 certifications demonstrating our commitment to quality, environmental stewardship, and workplace safety, we deliver customized solutions for satellite communications, defense, aerospace, weather monitoring, UAV, and direction-finding applications. Our expert engineering team provides comprehensive OEM services including design customization, material selection, rapid prototyping, and technical support throughout your project lifecycle. Contact craig@admicrowave.com today to discuss your specific Parabolic Antenna requirements and discover how our proven expertise, advanced manufacturing capabilities, and customer-focused approach can optimize your microwave communication systems.

References

1. Cutler, C.C., "Parabolic-Antenna Design for Microwaves," Proceedings of the Institute of Radio Engineers, November 1947.

2. Jasik, Henry, "Antenna Engineering Handbook," McGraw-Hill Book Company, First Edition, 1961.

3. Love, A.W., "Reflector Antennas," IEEE Press, 1978.

4. Rudge, A.W., Milne, K., Olver, A.D., and Knight, P., "The Handbook of Antenna Design," Peter Peregrinus Ltd., 1986.

5. International Telecommunication Union, "Recommendation ITU-R S.465: Reference Radiation Pattern for Earth Station Antennas in the Fixed-Satellite Service for Use in Coordination and Interference Assessment," ITU Radiocommunication Sector.

YOU MAY LIKE

VIEW MOREWaveguide Fixed Attenuator

VIEW MOREWaveguide Fixed Attenuator VIEW MOREWaveguide Probe Coupler

VIEW MOREWaveguide Probe Coupler VIEW MOREHigh Power Waveguide Circulator

VIEW MOREHigh Power Waveguide Circulator VIEW MOREHigh Power Waveguide Differential Phase Shift Circulator

VIEW MOREHigh Power Waveguide Differential Phase Shift Circulator VIEW MOREWaveguide Variable Attenuator

VIEW MOREWaveguide Variable Attenuator VIEW MOREHigh Power Waveguide Isolator

VIEW MOREHigh Power Waveguide Isolator VIEW MOREWG Bandpass Filter

VIEW MOREWG Bandpass Filter VIEW MOREWG Harmonic Filter

VIEW MOREWG Harmonic Filter