How does an E-plane tee differ from other types of T-junctions in waveguide technology?

In the complex world of microwave engineering and waveguide technology, understanding the fundamental differences between various T-junction configurations is crucial for optimal system design. An E-Plane Tee represents a specialized waveguide component that distinguishes itself through its unique geometric configuration and electromagnetic characteristics. Unlike H-plane tees or magic tees, the E-Plane Tee features its auxiliary arm junction positioned on the broad wall of the main waveguide, creating distinct field patterns and operational characteristics. This configuration results in specific phase relationships and power distribution properties that make it particularly valuable in applications requiring precise signal splitting and combining. The E-Plane Tee's design enables it to handle high-frequency signals with minimal insertion loss while maintaining excellent impedance matching, making it an essential component in satellite communications, radar systems, and aerospace applications where signal integrity is paramount.

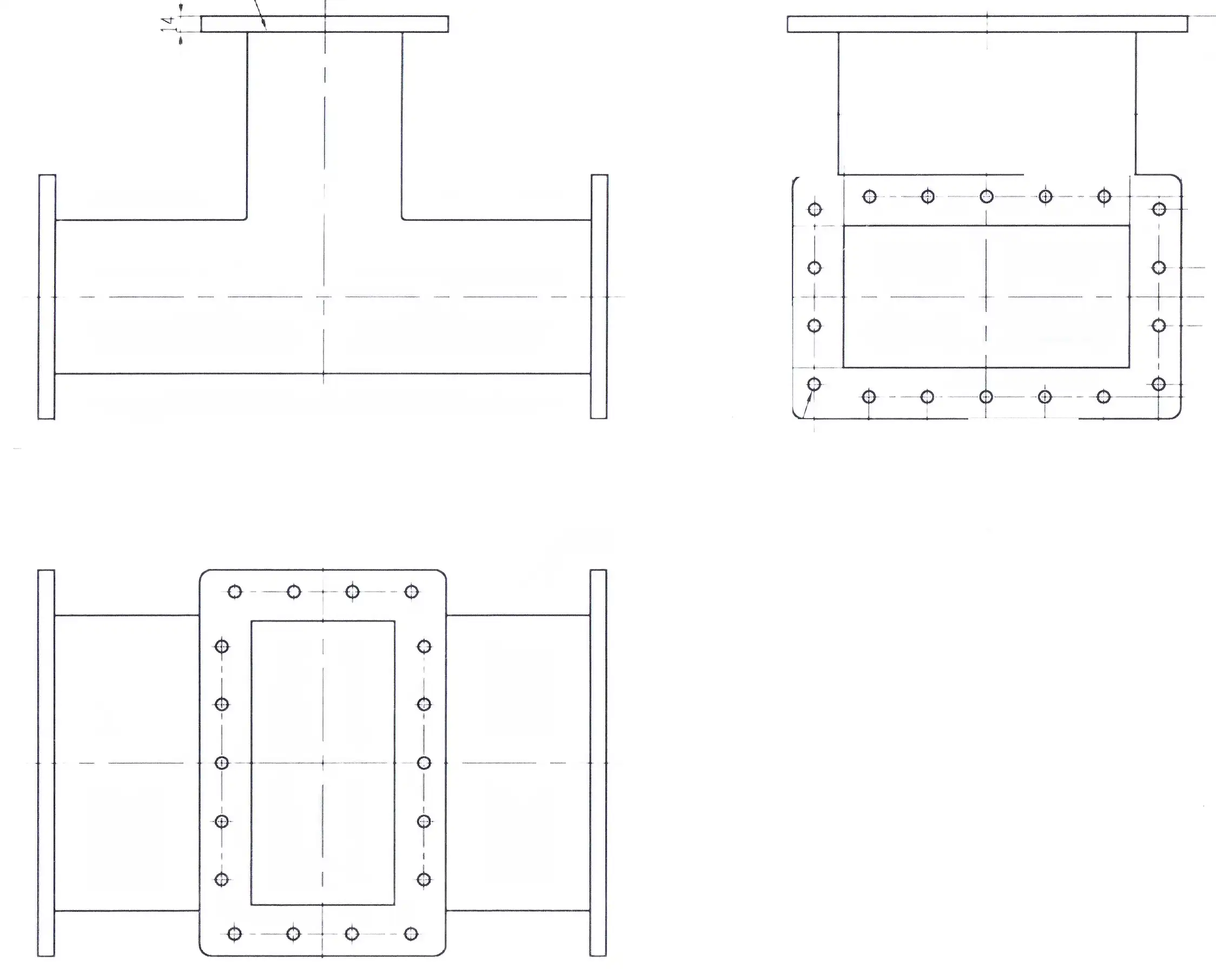

Fundamental Design Principles and Geometric Configuration

Physical Structure and Junction Placement

The E-Plane Tee's most distinguishing characteristic lies in its physical configuration, where the auxiliary arm connects to the broad wall of the main waveguide. This geometric arrangement creates a junction that is perpendicular to the electric field lines within the waveguide, hence the designation "E-plane." Advanced Microwave Technologies Co., Ltd. manufactures E-Plane Tees with precision-engineered junctions that ensure optimal electromagnetic coupling between the main waveguide and the auxiliary arm. The broad wall junction placement allows for efficient power transfer while maintaining the fundamental mode propagation characteristics. This design approach differs significantly from other T-junction types, as it creates a specific field pattern that enables predictable phase relationships between the output ports. The physical dimensions and tolerances of the E-Plane Tee are critical factors that determine its performance across various frequency ranges, with Advanced Microwave's designs supporting frequencies up to 110 GHz through careful geometric optimization and advanced construction techniques.

Electromagnetic Field Distribution Characteristics

The electromagnetic field distribution within an E-Plane Tee exhibits unique properties that set it apart from other waveguide junctions. When electromagnetic energy propagates through the main waveguide and encounters the E-Plane Tee junction, the electric field lines remain primarily oriented in their original direction while the magnetic field lines adapt to the new boundary conditions created by the auxiliary arm. This field configuration results in specific coupling mechanisms that determine how power is distributed between the output ports. The E-Plane Tee's field distribution creates a scenario where the signals at the two output ports maintain a 180-degree phase relationship, which is fundamentally different from the in-phase relationship found in H-plane configurations. Advanced Microwave's E-Plane Tee designs incorporate advanced construction techniques that minimize field disturbances and ensure optimal impedance matching, resulting in superior matching characteristics that reduce signal reflections and losses. The controlled field distribution also contributes to the component's ability to handle high power levels, making it suitable for demanding applications in aerospace and defense systems.

Manufacturing Precision and Quality Standards

The manufacturing process for E-Plane Tees requires exceptional precision to achieve the stringent performance specifications demanded by modern microwave systems. Advanced Microwave Technologies Co., Ltd. employs ISO:9001:2008 certified manufacturing processes that ensure consistent quality and reliability across all production runs. The precision machining of the junction interface is particularly critical, as even minor variations can significantly impact the component's electrical performance and impedance matching characteristics. The E-Plane Tee's manufacturing involves careful attention to surface finish, dimensional accuracy, and material selection to minimize insertion loss and maximize power handling capabilities. Quality control procedures include comprehensive testing using advanced microwave measurement equipment to verify performance parameters such as return loss, insertion loss, and isolation characteristics. The manufacturing process also incorporates RoHS-compliant materials, ensuring environmental responsibility without compromising performance. Each E-Plane Tee undergoes rigorous testing to validate its ability to maintain signal integrity across the specified frequency range, with particular attention to the unique phase relationships that characterize this type of junction.

Performance Characteristics and Electrical Properties

Insertion Loss and Signal Integrity

The E-Plane Tee's performance in terms of insertion loss represents one of its most significant advantages over alternative T-junction configurations. The unique junction geometry creates minimal discontinuities in the electromagnetic field pattern, resulting in exceptionally low insertion loss characteristics that preserve signal integrity throughout the transmission path. Advanced Microwave's E-Plane Tee designs achieve minimal signal loss through optimized junction geometries and precision manufacturing techniques that reduce parasitic reflections and mode conversions. The low insertion loss characteristic is particularly important in high-frequency applications where signal attenuation can significantly impact system performance. The E-Plane Tee's ability to maintain signal strength while providing reliable power splitting makes it an ideal choice for applications requiring multiple signal paths without compromising the original signal quality. The component's design ensures that the insertion loss remains consistently low across the entire operating frequency range, providing predictable performance for system designers. This characteristic, combined with the E-Plane Tee's robust construction, enables reliable operation even in harsh environmental conditions where signal integrity is critical for mission success.

Power Handling Capabilities and Thermal Management

Power handling capability represents another crucial performance parameter that distinguishes the E-Plane Tee from other waveguide junction types. The junction's design and construction enable it to support high power levels without experiencing breakdown or performance degradation, making it suitable for high-power microwave applications. Advanced Microwave's E-Plane Tee incorporates robust materials and advanced construction techniques that ensure reliable operation under high-power conditions. The thermal management characteristics of the E-Plane Tee are enhanced by its geometric configuration, which provides efficient heat dissipation pathways that prevent localized heating and potential component failure. The power handling capability is further enhanced by the precision manufacturing processes that eliminate sharp edges and discontinuities that could create field concentrations and potential breakdown points. The E-Plane Tee's ability to handle high power levels while maintaining low insertion loss makes it particularly valuable in radar systems and satellite communication applications where both high power and signal fidelity are essential. The component's durable and reliable construction ensures long-lasting performance even when subjected to repeated high-power cycling and varying environmental conditions.

Frequency Response and Bandwidth Characteristics

The frequency response characteristics of an E-Plane Tee demonstrate its versatility across a wide range of microwave applications. The component's design enables consistent performance across broad frequency ranges, with Advanced Microwave's E-Plane Tees supporting frequencies up to 110 GHz through careful optimization of the junction geometry and dimensional parameters. The bandwidth characteristics are determined by the junction's ability to maintain proper impedance matching and minimize reflections across the operating frequency range. The E-Plane Tee's frequency response exhibits excellent stability, ensuring that the phase relationships and power distribution characteristics remain consistent regardless of the operating frequency within the specified range. This broad bandwidth capability makes the E-Plane Tee particularly suitable for applications involving frequency-agile systems or broadband communications where consistent performance across multiple frequencies is essential. The component's frequency response is further enhanced by Advanced Microwave's customizable design options, which allow for optimization of the frequency characteristics to match specific application requirements. The stable frequency response, combined with the E-Plane Tee's other performance characteristics, makes it an ideal choice for modern communication systems that demand reliable operation across diverse frequency bands.

Applications and System Integration Advantages

Satellite Communication Systems Implementation

In satellite communication systems, the E-Plane Tee plays a critical role in signal distribution and power splitting applications where reliable performance and minimal loss are essential for maintaining communication link quality. The component's unique phase characteristics make it particularly suitable for applications requiring specific signal routing and combining functions in satellite transponders and ground station equipment. Advanced Microwave's E-Plane Tee designs are widely used in satellite communications for signal distribution and splitting, providing the reliability and performance required for continuous operation in space-based systems. The component's compact design enables efficient integration into satellite payload systems where space and weight constraints are critical considerations. The E-Plane Tee's ability to maintain signal integrity while providing precise power distribution makes it an essential component in satellite communication systems that must operate reliably for extended periods without maintenance. The environmental resilience of Advanced Microwave's E-Plane Tee designs ensures consistent performance despite the extreme temperature variations and radiation exposure encountered in satellite applications. The component's proven reliability in satellite systems demonstrates its capability to meet the stringent requirements of space-qualified hardware while providing the performance characteristics essential for successful mission completion.

Radar System Integration and Performance

Radar systems represent another major application area where the E-Plane Tee's unique characteristics provide significant advantages over alternative T-junction configurations. The component's ability to distribute power with minimal loss while maintaining specific phase relationships makes it ideal for radar applications requiring precise beam forming and signal processing capabilities. Advanced Microwave's E-Plane Tee supports radar applications by distributing power with minimal loss, ensuring that radar systems can achieve maximum detection range and resolution performance. The component's high power handling capability enables its use in high-power radar transmitters where reliable operation under extreme conditions is essential for mission success. The E-Plane Tee's consistent performance characteristics across wide frequency ranges make it suitable for frequency-agile radar systems that must operate across multiple frequency bands to counter electronic warfare threats. The component's robust construction and reliable performance ensure that radar systems can maintain operational capability even in harsh environmental conditions where other components might fail. The integration of E-Plane Tees in radar systems contributes to overall system reliability and performance, enabling radar operators to achieve superior detection and tracking capabilities while maintaining system availability.

Aerospace and Defense Applications

The aerospace and defense industries represent critical application areas where the E-Plane Tee's performance characteristics and reliability are essential for mission success. The component's ability to operate reliably under extreme environmental conditions makes it suitable for aircraft, missile, and spacecraft applications where failure is not an option. Advanced Microwave's E-Plane Tee is crucial for power splitting and combining in navigation and defense systems, ensuring reliable signal transmission in high-frequency applications where precision and reliability are paramount. The component's compact design and lightweight construction make it ideal for airborne applications where size and weight constraints are critical design considerations. The E-Plane Tee's proven performance in aerospace applications demonstrates its ability to meet the stringent requirements of military and space-qualified hardware while providing the electrical performance essential for system operation. The component's resistance to vibration, shock, and temperature extremes ensures reliable operation throughout the operational life of aerospace and defense systems. The use of E-Plane Tees in navigation systems contributes to positioning accuracy and system reliability, enabling precise navigation capabilities that are essential for both civilian and military aviation applications.

Conclusion

The E-Plane Tee represents a specialized waveguide component that offers distinct advantages over other T-junction configurations through its unique geometric design and electromagnetic characteristics. Its broad wall junction placement, superior power handling capabilities, and exceptional frequency response make it an indispensable component in modern microwave systems. Advanced Microwave Technologies Co., Ltd.'s expertise in E-Plane Tee design and manufacturing ensures optimal performance across diverse applications, from satellite communications to aerospace systems, providing the reliability and precision that today's demanding applications require.

Ready to enhance your microwave system performance with precision-engineered E-Plane Tees? Advanced Microwave Technologies Co., Ltd. combines over 20 years of manufacturing expertise with state-of-the-art facilities equipped with measurement capabilities up to 110 GHz. Our advantages include a perfect supply chain system, rich production experience, professional technical R&D team, fast delivery, competitive pricing, strict quality control, and strong after-sales support. We offer integrated production and R&D services with global export capabilities, providing ISO:9001:2008 certified and RoHS-compliant products for satellite communications, defense, aerospace, and navigation applications. Whether you're a multinational corporation or an R&D-driven company, we deliver customized OEM solutions with quick prototyping turnaround, comprehensive technical support, and efficient manufacturing processes. Contact our expert engineers today at mia@admicrowave.com to discuss your specific requirements and discover how our E-Plane Tee solutions can optimize your system performance.

References

1. Pozar, David M. "Microwave Engineering: Power Dividers and Directional Couplers." Fourth Edition, John Wiley & Sons, 2012.

2. Collin, Robert E. "Foundations for Microwave Engineering: Waveguide Theory and Applications." Second Edition, McGraw-Hill Education, 2001.

3. Matthaei, George L., Leo Young, and E.M.T. Jones. "Microwave Filters, Impedance-Matching Networks, and Coupling Structures." Artech House Publishers, 1980.

4. Rizzi, Peter A. "Microwave Engineering: Passive Circuits and Applications to Systems Design." Prentice Hall, 1988.

5. Sorrentino, Roberto and Giovanni Bianchi. "Microwave and RF Engineering: Passive and Active Circuit Design." John Wiley & Sons, 2007.

6. Edwards, Terry C. and Michael B. Steer. "Foundations of Interconnect and Microstrip Design." Third Edition, John Wiley & Sons, 2000.