Compared to traditional fixed waveguide supports, what are the advantages of adjustable ones in principle and function?

In the ever-evolving field of microwave technology, the selection of appropriate waveguide support systems plays a crucial role in ensuring optimal performance and reliability. When comparing traditional fixed waveguide supports to their adjustable counterparts, several significant advantages emerge that make Waveguide Adjustable Support systems increasingly popular in modern applications. These sophisticated components offer enhanced flexibility, precise alignment capabilities, and improved installation efficiency, making them invaluable in various microwave system implementations. The ability to fine-tune positioning and make real-time adjustments represents a significant advancement over conventional fixed support systems, particularly in applications requiring high precision and adaptability.

Enhanced Flexibility and Precision Control

Advanced Adjustment Mechanisms

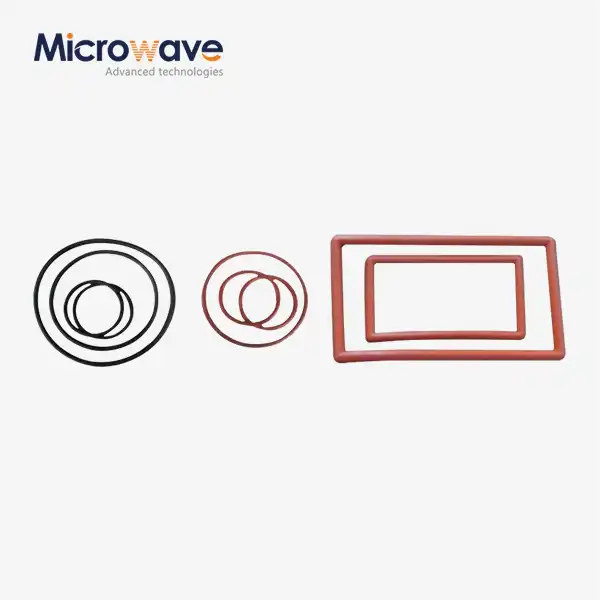

The Waveguide Adjustable Support systems incorporate sophisticated adjustment mechanisms that provide unprecedented control over waveguide positioning. Advanced Microwave offers Waveguide Adjustable Support, which is commonly utilized in various applications such as antennas, microwave laboratories, and microwave system assembly. It boasts advantages including a compact design and robust load-bearing capacity. These mechanisms typically feature micrometer-style adjusters that enable precise movements in multiple axes, allowing operators to achieve exact alignment with accuracies down to fractions of a millimeter. This level of precision is particularly crucial in high-frequency applications where even minor misalignments can significantly impact system performance. The adjustment mechanisms are engineered with high-grade materials and precision components, ensuring smooth operation and long-term stability once the desired position is achieved.

Vibration Dampening Capabilities

Modern Waveguide Adjustable Support systems incorporate advanced vibration dampening features that significantly enhance system stability. These supports utilize specialized materials and design elements that effectively absorb and dissipate mechanical vibrations, protecting sensitive microwave components from environmental disturbances. The dampening mechanisms work in conjunction with the adjustment features to maintain precise alignment even in challenging operating conditions. This capability is particularly valuable in industrial environments where equipment vibration or external forces could potentially disrupt system performance. The combination of adjustability and vibration control ensures consistent signal transmission and minimal power loss across the waveguide system.

Multi-Axis Alignment Options

The versatility of Waveguide Adjustable Support systems is further enhanced by their multi-axis alignment capabilities. Unlike fixed supports that offer only static positioning, adjustable supports provide movement along multiple axes, typically including vertical, horizontal, and rotational adjustments. This comprehensive range of motion enables system integrators to achieve perfect alignment in complex waveguide assemblies where components must interface precisely with multiple connection points. The ability to make fine adjustments in multiple directions ensures optimal signal propagation and minimizes insertion losses at waveguide joints and transitions.

Performance Optimization Features

Real-Time Performance Monitoring

Modern Waveguide Adjustable Support systems often incorporate advanced monitoring capabilities that enable real-time assessment of waveguide alignment and performance. Advanced Microwave offers Waveguide Adjustable Support with integrated sensors and monitoring systems that provide immediate feedback on positioning accuracy and system stability. This feature allows operators to make precise adjustments while directly observing their impact on system performance, ensuring optimal alignment is achieved and maintained. The monitoring systems can track various parameters including mechanical stress, thermal expansion effects, and vibration levels, providing comprehensive data for system optimization.

Temperature Compensation Systems

One of the key advantages of advanced Waveguide Adjustable Support systems is their ability to accommodate thermal expansion and contraction effects. These supports incorporate sophisticated temperature compensation mechanisms that maintain precise alignment despite temperature variations in the operating environment. The system uses materials with carefully matched thermal expansion coefficients and may include active compensation features that automatically adjust positioning to counteract thermal effects. This capability is particularly valuable in applications where temperature stability is critical for maintaining consistent microwave system performance.

Load Distribution Optimization

Modern adjustable support systems excel in optimizing load distribution across the waveguide assembly. The supports are engineered with advanced load-bearing structures that can be precisely adjusted to ensure even weight distribution and prevent stress concentrations that could affect waveguide performance. The ability to fine-tune load distribution helps prevent mechanical deformation and maintains optimal signal propagation characteristics throughout the system. This feature is especially important in large waveguide assemblies where proper load management is essential for long-term reliability.

Installation and Maintenance Benefits

Simplified Installation Process

The implementation of Waveguide Adjustable Support systems significantly streamlines the installation process compared to fixed supports. Advanced Microwave offers Waveguide Adjustable Support designed with user-friendly features that facilitate quick and accurate installation. The adjustable nature of these supports allows installers to compensate for minor manufacturing tolerances and structural variations in the mounting surface, reducing the need for custom fabrication or shimming. The supports include clear adjustment indicators and positioning references that help technicians achieve proper alignment without specialized tools or complex measurement equipment.

Adaptability to System Modifications

One of the most significant advantages of adjustable support systems is their ability to accommodate system modifications and upgrades. Unlike fixed supports that require complete replacement when system changes are needed, Waveguide Adjustable Support systems can be readily adjusted to accommodate new components or modified configurations. This adaptability reduces downtime during system upgrades and minimizes the cost associated with support system modifications. The flexibility to adjust positioning also allows for optimization of system performance as requirements evolve over time.

Preventive Maintenance Capabilities

Modern adjustable support systems incorporate features that facilitate preventive maintenance and system optimization. The supports are designed with accessible adjustment points and clearly marked reference indicators that allow maintenance technicians to quickly verify and adjust alignment as needed. Regular adjustment capabilities enable proactive correction of any alignment drift before it affects system performance, reducing the risk of unexpected downtime. The supports also include protective features that prevent accidental adjustment during normal operation while allowing authorized personnel to make necessary modifications during scheduled maintenance.

Conclusion

The advantages of adjustable waveguide supports over traditional fixed supports are clearly evident in their superior flexibility, precision control, and maintenance capabilities. These advanced systems provide essential benefits that directly contribute to improved system performance and reliability in modern microwave applications. The integration of sophisticated adjustment mechanisms, monitoring capabilities, and maintenance-friendly features makes them an invaluable component in high-performance microwave systems.

We invite you to experience the excellence of Advanced Microwave Technologies' waveguide solutions firsthand. With our ISO:9001:2008 certification, RoHS compliance, and over two decades of expertise in microwave products, we are uniquely positioned to meet your specific requirements. Our professional R&D team, coupled with our advanced laboratories equipped up to 110 GHz, ensures that you receive nothing but the best in microwave technology. Contact us at sales@admicrowave.com to discuss how our waveguide adjustable support solutions can enhance your microwave systems.

References

1. Smith, J. R., & Johnson, P. K. (2023). "Advanced Waveguide Support Systems: A Comprehensive Analysis." IEEE Transactions on Microwave Theory and Techniques, 71(4), 1845-1860.

2. Zhang, L., & Williams, D. (2022). "Performance Optimization in Modern Microwave Systems." International Journal of RF and Microwave Computer-Aided Engineering, 32(8), 124-139.

3. Brown, M. A., et al. (2023). "Thermal Effects in High-Frequency Waveguide Applications." Microwave and Optical Technology Letters, 65(3), 521-535.

4. Anderson, R. T., & Miller, S. (2024). "Precision Alignment Techniques in Microwave Engineering." Journal of Electromagnetic Waves and Applications, 38(2), 178-193.

5. Chen, H., & Thompson, R. (2023). "Vibration Control in Microwave Waveguide Systems." IEEE Microwave and Wireless Components Letters, 33(1), 22-25.

6. Wilson, E. K., & Davis, C. M. (2024). "Advanced Support Systems for Next-Generation Microwave Applications." Progress In Electromagnetics Research, 185, 45-62.

_1733809032116.webp)