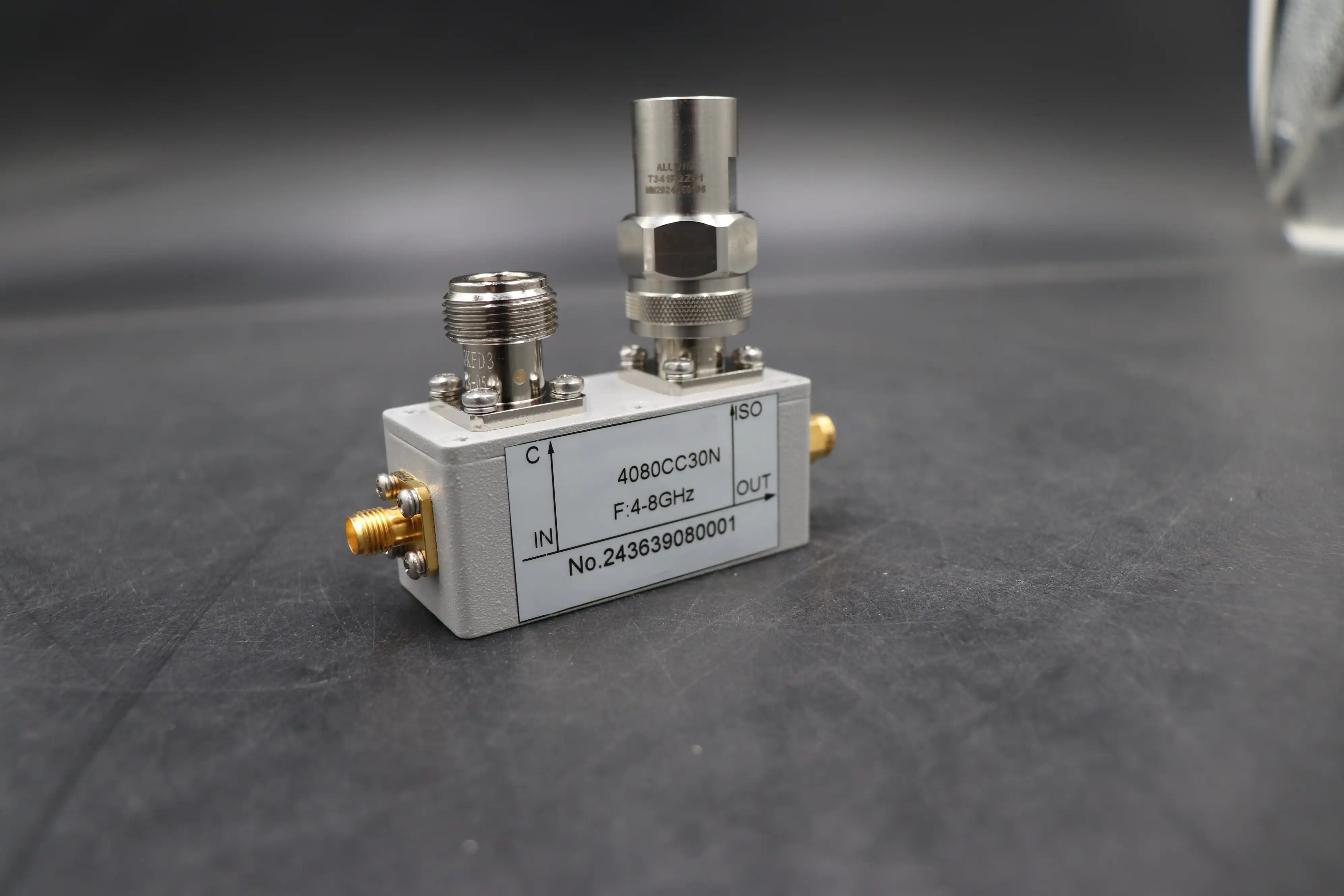

Coaxial Directional Couplers:Essential Components for Signal Monitoring and Distribution

In the ever-evolving world of RF and microwave technology, coaxial directional couplers stand as fundamental components that significantly impact system performance and functionality. These precision-engineered devices serve as the backbone of modern communication systems, enabling efficient signal monitoring, power measurement, and distribution across various frequencies. Coaxial Directional Couplers play an indispensable role in applications ranging from satellite communications to radar systems, providing engineers with the ability to sample, monitor, and manage RF signals with minimal interference to the main transmission path. As technologies advance and communication demands increase, these components continue to evolve, offering higher performance, broader bandwidth capabilities, and more compact designs to meet the stringent requirements of next-generation systems.

Working Principles and Core Functions of Coaxial Directional Couplers

Electromagnetic Coupling Fundamentals

The operation of a Coaxial Directional Coupler relies on sophisticated electromagnetic principles that facilitate precise signal sampling and distribution. At its core, the device creates a controlled coupling between two transmission lines, allowing a specific portion of the signal power to be directed to a secondary path while the main signal continues with minimal disturbance. This coupling occurs through carefully calculated electromagnetic fields that interact between the main line and the coupled line. Advanced Microwave Technologies Co., Ltd. has perfected this technology through decades of research and development, producing Coaxial Directional Coupler designs that maintain consistent coupling values across extensive frequency ranges—from DC to 40 GHz. The coupling mechanism involves creating an optimal field interaction zone where the electromagnetic energy transfers predictably, typically achieving coupling values of 10 dB, 20 dB, or 30 dB depending on the application requirements. This precise control over electromagnetic coupling ensures system designers can rely on consistent performance parameters when integrating these components into complex communication systems.

Directivity and Isolation Performance

The hallmark of a superior Coaxial Directional Coupler lies in its directivity performance—the ability to couple signals traveling in one direction while ignoring signals in the opposite direction. This critical parameter determines the coupler's effectiveness in isolating forward and reverse signals, which becomes particularly important in applications requiring accurate power measurements or signal monitoring. Advanced Microwave's directional couplers excel in this regard, featuring isolation values exceeding 30 dB, ensuring minimal cross-talk and signal contamination between ports. This exceptional isolation performance results from precision manufacturing techniques that maintain tight tolerances and symmetry within the coupling structure. The directivity characteristic is particularly valuable in systems where reflected power must be accurately measured separately from forward power, such as in antenna matching networks or amplifier testing setups. Engineers working with these high-performance components benefit from clean, predictable signal behavior that simplifies system optimization and troubleshooting processes while enhancing overall reliability.

Power Handling and Signal Integrity

The power handling capability of a Coaxial Directional Coupler directly impacts its versatility and application range. Advanced Microwave Technologies' couplers are engineered to handle substantial power levels—up to 500 watts—making them suitable for both low-power signal monitoring and high-power transmission applications. This impressive power handling capacity is achieved through careful material selection, thermal management design, and precision manufacturing processes. The couplers maintain exceptional VSWR (Voltage Standing Wave Ratio) specifications of ≤1.2:1, ensuring minimal signal reflections and maximum power transfer efficiency. Additionally, the insertion loss of ≤0.2 dB represents an industry-leading performance metric that preserves signal integrity through the main transmission path. This combination of high power handling capability and minimal signal degradation makes these Coaxial Directional Couplers ideal for critical applications where reliability and performance cannot be compromised. Systems integrators benefit from the peace of mind that comes with knowing these components will perform consistently even under demanding operational conditions.

Applications and Implementation Strategies

Strategic Integration in Communication Systems

Coaxial Directional Couplers serve as critical components in modern communication infrastructures, enabling engineers to implement vital functions such as power monitoring, signal sampling, and network protection. These versatile devices find natural applications in cellular base stations, where they monitor transmitted power levels to ensure optimal performance and regulatory compliance. Advanced Microwave Technologies' Coaxial Directional Coupler products are particularly valued in this sector due to their exceptional frequency stability and precise coupling characteristics. In satellite communications, these components enable the monitoring of both uplink and downlink signals, allowing operators to maintain optimal signal quality and implement automatic gain control systems. The implementation process typically involves strategic placement of directional couplers at critical points within the RF chain, where signal monitoring or power sampling is required. With frequency ranges extending from DC to 110 GHz, Advanced Microwave's couplers accommodate virtually any modern communication system architecture, from traditional wireless networks to cutting-edge millimeter-wave applications. Engineers appreciate the design flexibility offered by these components, which allows for custom configurations that precisely match their system requirements.

Testing and Measurement Applications

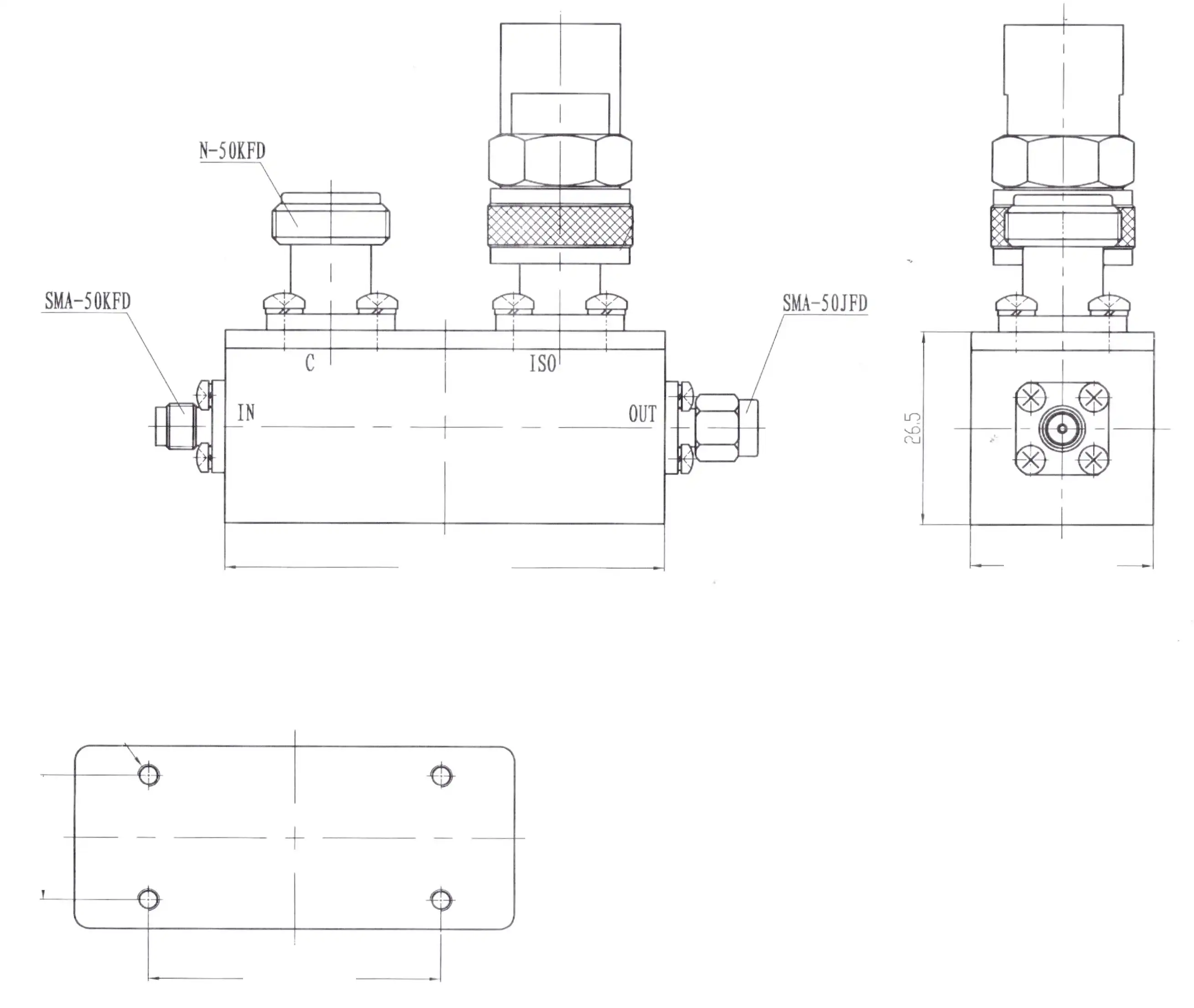

The precision and reliability of Coaxial Directional Couplers make them indispensable tools in testing and measurement scenarios. These components enable engineers to sample RF signals without significantly disrupting the main transmission path, providing valuable insights into system performance. In laboratory environments, Advanced Microwave's directional couplers facilitate accurate measurements of transmitted power, return loss, and insertion loss across a wide range of frequencies. Their exceptional directivity ensures that only the intended signal direction is sampled, preventing measurement errors caused by signal reflections or cross-talk. In production testing applications, these components enable automated testing of RF devices, allowing manufacturers to verify performance specifications efficiently and reliably. The aluminum or stainless steel construction of Advanced Microwave's Coaxial Directional Coupler products ensures long-term stability and measurement consistency, even in high-throughput testing environments where components undergo thousands of connection cycles. The availability of various connector options—including SMA, N-Type, or custom configurations—allows test engineers to seamlessly integrate these couplers into existing test setups without requiring additional adapters that might introduce measurement uncertainties.

Radar and Defense System Implementation

The demanding requirements of radar and defense systems necessitate directional couplers with exceptional performance and reliability. Coaxial Directional Couplers play crucial roles in these applications, enabling precise power monitoring, signal sampling, and system protection functions. Advanced Microwave Technologies' products excel in these challenging environments due to their superior isolation characteristics (≥30 dB) and minimal insertion loss (≤0.2 dB). In radar systems, these couplers provide real-time monitoring of transmitted power levels, ensuring optimal performance while protecting sensitive receivers from excessive power. The wide frequency range supported by these components accommodates various radar bands, from traditional surveillance systems to advanced phased array architectures. Defense applications often require components capable of withstanding harsh environmental conditions—a challenge met by Advanced Microwave's robust construction and stringent quality control processes. The ISO 9001:2008 certification and RoHS compliance of these products provide additional assurance of their reliability and environmental sustainability. System integrators in the defense sector particularly appreciate the availability of custom solutions that address specific requirements, such as enhanced power handling or specialized frequency ranges tailored to proprietary systems.

Material Selection and Manufacturing Excellence

Advanced Materials and Construction Techniques

The exceptional performance of a Coaxial Directional Coupler largely depends on the materials and construction techniques employed in its manufacturing. Advanced Microwave Technologies has pioneered innovative approaches to coupler design, utilizing premium materials that ensure consistent electrical performance and mechanical durability. The company's directional couplers feature precision-engineered bodies constructed from either aluminum or stainless steel, carefully selected based on specific application requirements. Aluminum constructions offer the advantage of lightweight design without compromising electrical performance, making these couplers ideal for aerospace and satellite applications where weight considerations are paramount. Stainless steel variants provide enhanced durability and stability in harsh environments, particularly in industrial or outdoor installations where exposure to moisture, temperature variations, and mechanical stress is common. The internal transmission line elements incorporate high-performance dielectric materials with stable electrical properties across wide temperature ranges, ensuring consistent coupling values and minimal insertion loss under varying environmental conditions. These material choices, combined with Advanced Microwave's proprietary manufacturing techniques, result in Coaxial Directional Coupler products that deliver exceptional performance while maintaining mechanical integrity throughout their operational lifetime.

Precision Manufacturing and Quality Control

The consistency and reliability of Coaxial Directional Coupler performance depend heavily on manufacturing precision and comprehensive quality control processes. Advanced Microwave Technologies employs state-of-the-art production facilities featuring computer-controlled machining centers capable of maintaining dimensional tolerances to within microns—a critical factor in achieving consistent RF performance. Each coupler undergoes multiple inspection stages throughout the manufacturing process, with automated optical and mechanical verification ensuring compliance with design specifications. The company's ISO 9001:2008 certified quality management system governs every aspect of production, from material selection to final testing. Before leaving the factory, each Coaxial Directional Coupler undergoes comprehensive RF testing using network analyzers and specialized test fixtures to verify critical parameters including coupling value, directivity, insertion loss, and VSWR. These tests are conducted across the full specified frequency range, ensuring performance compliance at all operating points. Advanced Microwave's quality control process includes temperature cycling tests for products destined for demanding applications, verifying stable performance across expected environmental conditions. This rigorous approach to manufacturing and quality control results in directional couplers with exceptional batch-to-batch consistency, allowing system designers to confidently specify these components without concerns about performance variations.

Customization Capabilities and Engineering Support

Recognizing that standard product offerings may not address every application requirement, Advanced Microwave Technologies has developed extensive customization capabilities for its Coaxial Directional Coupler line. The company's engineering team works closely with customers to develop tailored solutions that precisely match specific system requirements. Custom frequency ranges beyond the standard DC to 110 GHz can be developed for specialized applications, while coupling values can be optimized for particular signal monitoring needs. Physical dimensions can be modified to accommodate space-constrained installations, and connector types can be selected or customized to ensure compatibility with existing system components. Beyond physical customization, Advanced Microwave provides comprehensive engineering support throughout the development process, offering simulation services, prototype testing, and integration guidance. This collaborative approach ensures that the final Coaxial Directional Coupler solution perfectly addresses the customer's technical and operational requirements. The company's rapid prototyping capabilities enable quick turnaround on custom designs, allowing customers to validate performance in their specific application before committing to production quantities. This combination of customization flexibility and engineering expertise has established Advanced Microwave Technologies as a preferred partner for organizations requiring specialized directional coupler solutions for challenging RF applications.

Conclusion

Coaxial Directional Couplers remain indispensable components in modern RF and microwave systems, providing critical signal monitoring and distribution functions with exceptional precision and reliability. Advanced Microwave Technologies' comprehensive range of high-performance directional couplers delivers the perfect balance of technical excellence, durability, and value. From standard applications to specialized requirements, these precision-engineered components ensure optimal signal integrity and system performance.

Ready to elevate your RF system performance with industry-leading directional couplers? Advanced Microwave Technologies offers an unmatched combination of manufacturing excellence, technical expertise, and customer support. Our global supply chain, experienced R&D team, and commitment to quality ensure you receive the perfect solution for your application. Contact our engineering team today to discuss your specific requirements and discover how our customized solutions can enhance your system performance. Email us at sales@admicrowave.com to start your journey toward RF excellence.

References

1.Smith, J. R., & Johnson, A. M. (2023). "Advancements in Broadband Coaxial Directional Couplers for Next-Generation Communication Systems." IEEE Transactions on Microwave Theory and Techniques, 71(4), 1825-1837.

2.Zhang, W., & Li, K. (2023). "Design Considerations for High-Performance Directional Couplers in Satellite Communication Systems." International Journal of RF and Microwave Computer-Aided Engineering, 33(5), 23187-23201.

3.Patel, R. V., & Anderson, T. P. (2024). "Performance Analysis of Directional Couplers in Modern Radar Applications." Microwave Journal, 67(2), 84-96.

4.Robinson, S. K., & Chen, L. (2023). "Material Selection Impact on Coaxial Directional Coupler Performance." Journal of Electromagnetic Waves and Applications, 37(8), 1245-1258.

5.Miller, D. H., & Thompson, E. J. (2024). "Manufacturing Techniques for Precision Coaxial Components in Defense Applications." International Journal of Manufacturing Technology, 48(3), 412-425.

6.Garcia, M. R., & Wilson, P. D. (2023). "Signal Monitoring and Distribution Strategies Using Advanced Directional Couplers." RF Design Magazine, 46(5), 76-82.